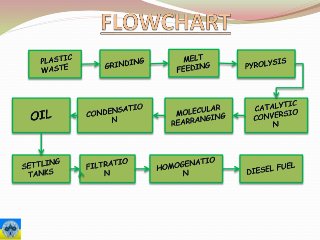

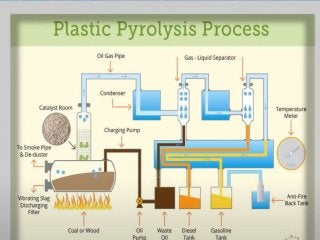

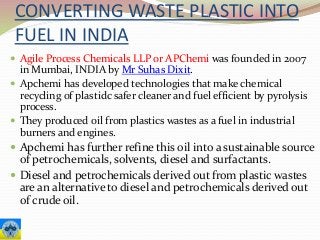

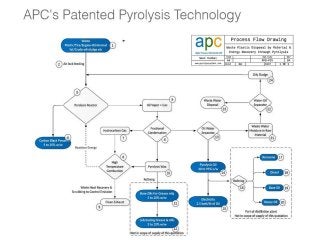

This document summarizes a student project on producing thermofuel from waste plastics. The student, Hritwik Ghosh, aims to address both environmental pollution from plastic waste and the need for alternative fuels. The process involves liquefying plastic waste through pyrolysis to produce a fuel that can be used in diesel engines, vehicles, and generators. Advantages include reducing landfill waste and greenhouse gas emissions while creating new jobs and revenue streams from waste treatment. The student cites an example of a company in India that has established a plant to produce diesel fuel from plastic waste.