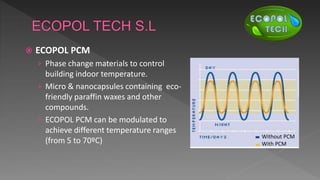

Ecopol Tech specializes in innovative and environmentally friendly polymers, focusing on intensive R&D and addressing challenges in polymer chemistry and encapsulation. They offer various products, including solvent-free polyurethane resins, high-performance coatings, and phase change materials for temperature control, aimed at multiple industries such as construction, textiles, and coatings. Additionally, the company provides technological consulting and develops specialty polymers and nanostructured materials for other companies.