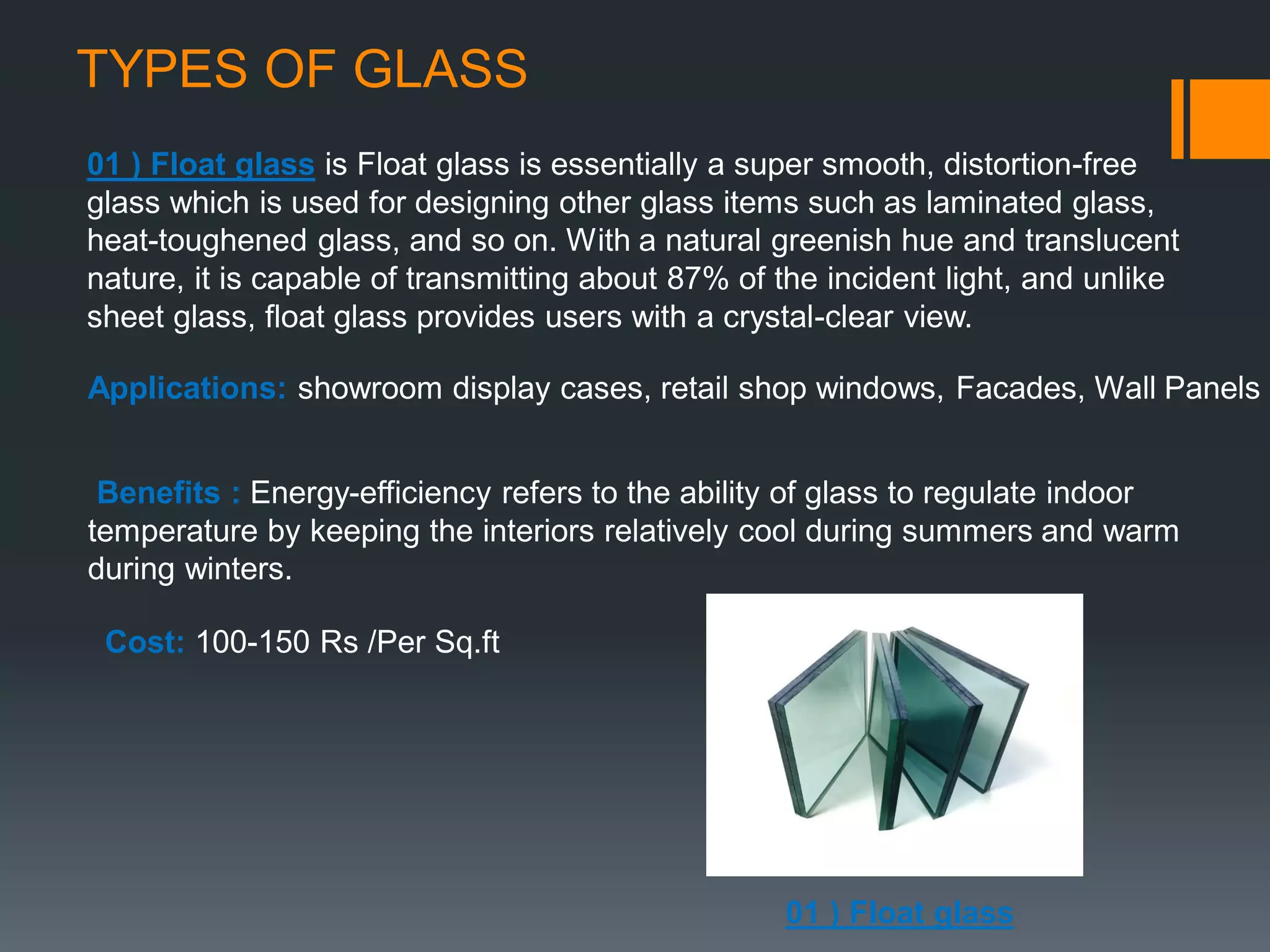

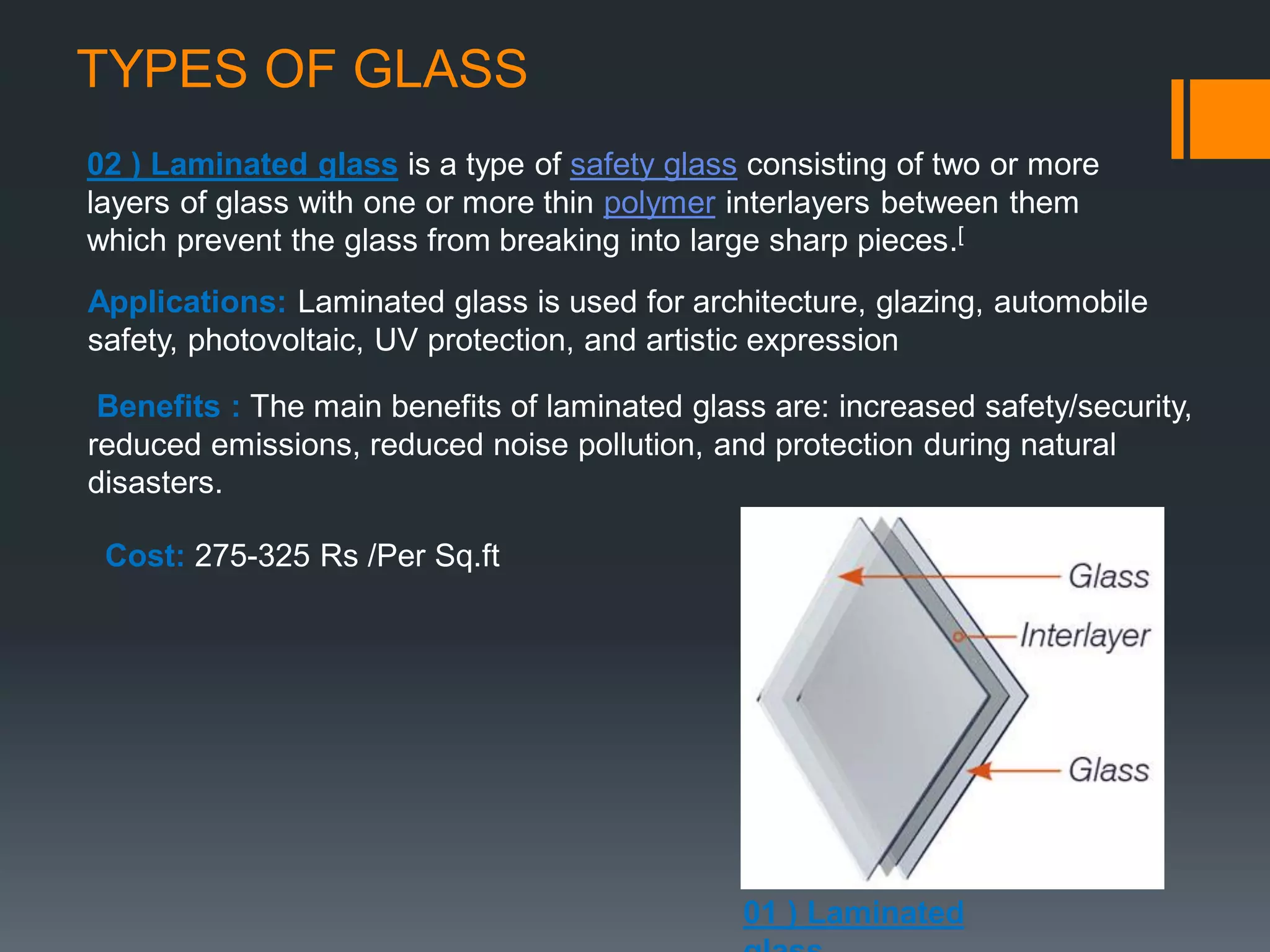

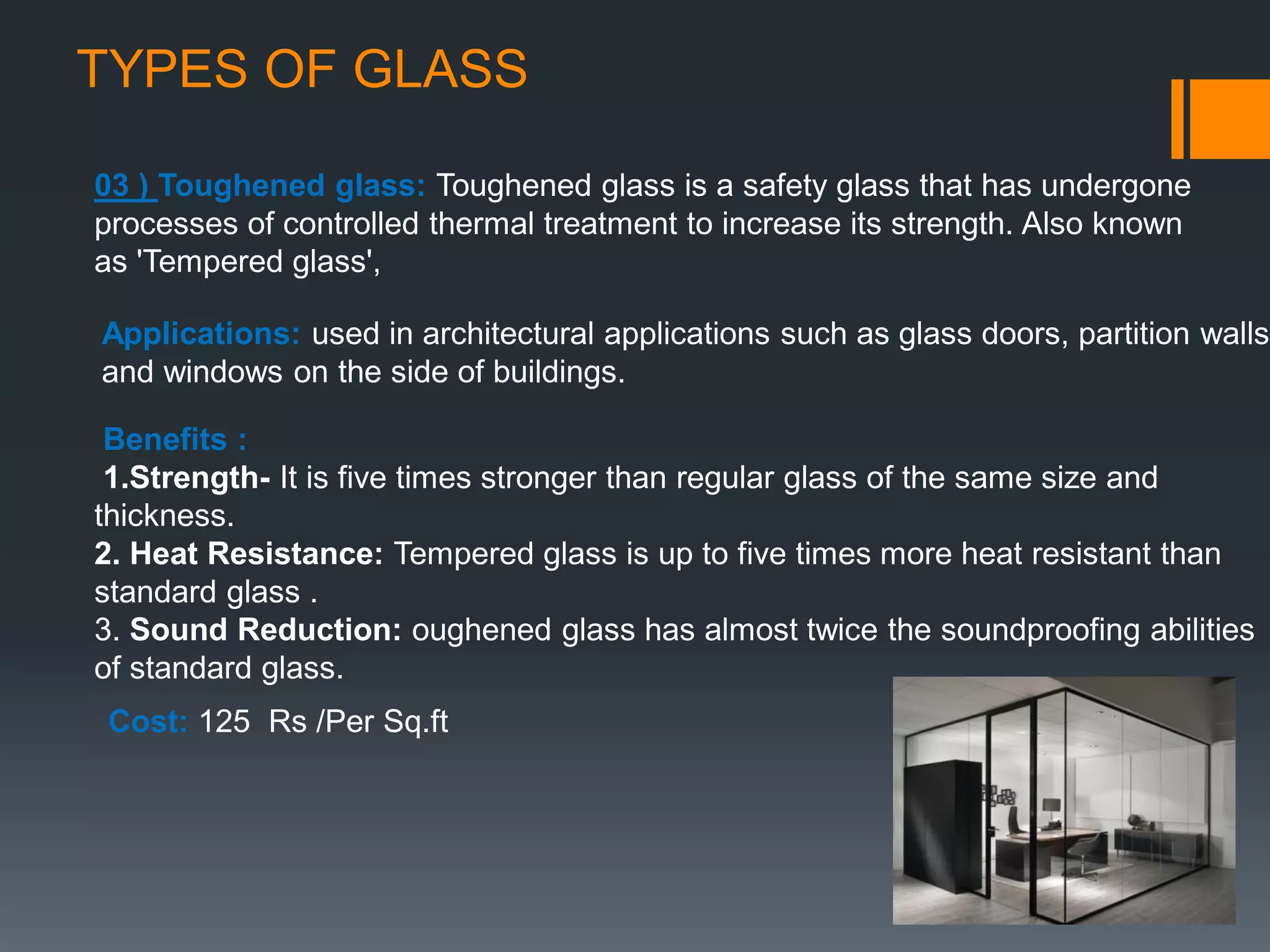

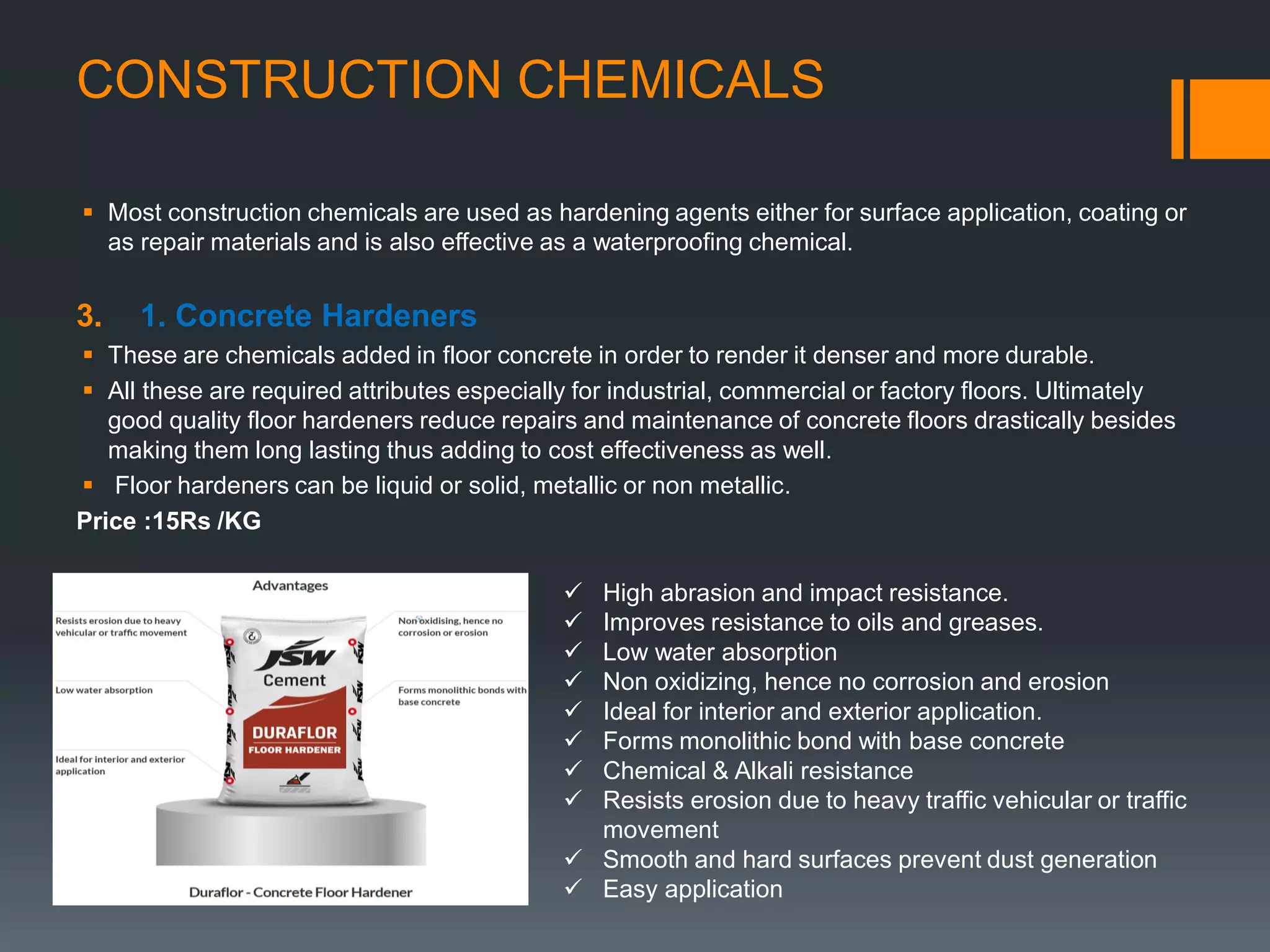

This document discusses various construction materials including glass, chemicals, fabrics, and polymers. It provides details on three types of glass - float glass, laminated glass, and toughened glass. It also discusses various construction chemicals such as concrete hardeners, epoxy coatings, and mould releasing agents. Three construction fabrics - geotextile, fiberglass, and carbon fibre are outlined. Finally, it covers two construction polymers - rubber and polypropylene. The document provides information on applications, benefits, and costs for each material.