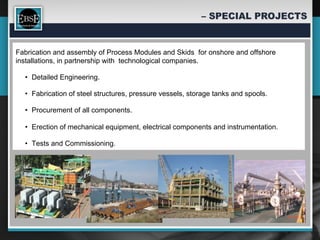

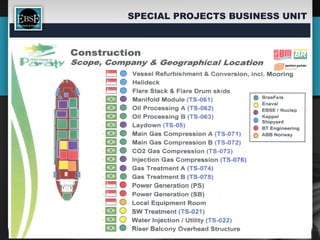

EBSE Engenharia de Soluções is a Brazilian factory founded in 1913 that produces industrial equipment, large diameter pipes, and heavy duty steel components. It was acquired in 2000 by the MPE Group. The factory is located on 100,000 square meters near transport infrastructure in Rio de Janeiro. EBSE has expertise in designing, fabricating, and assembling equipment and pipes for industries such as oil and gas, energy, and pulp and paper. It is certified to various international quality and safety standards.