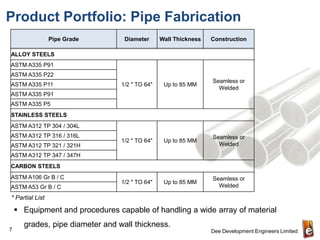

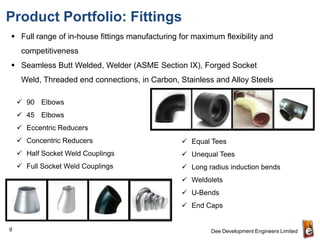

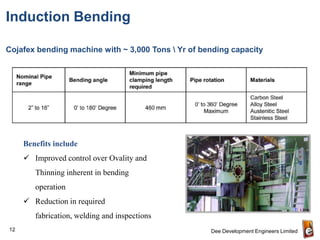

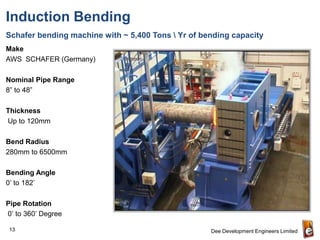

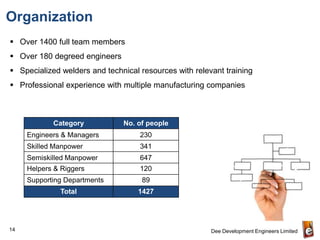

Dee Development Engineers Limited is a global manufacturer of piping systems and fittings established in 1983. It has over 1400 employees including 200+ engineers and operates manufacturing facilities in India with a combined annual capacity of over 58,000 metric tons. The company specializes in the fabrication of carbon, stainless, and alloy steel pipes and fittings for industries including power, chemical, and oil and gas. It has extensive quality certifications and offers customized engineering and fabrication services to customers worldwide.