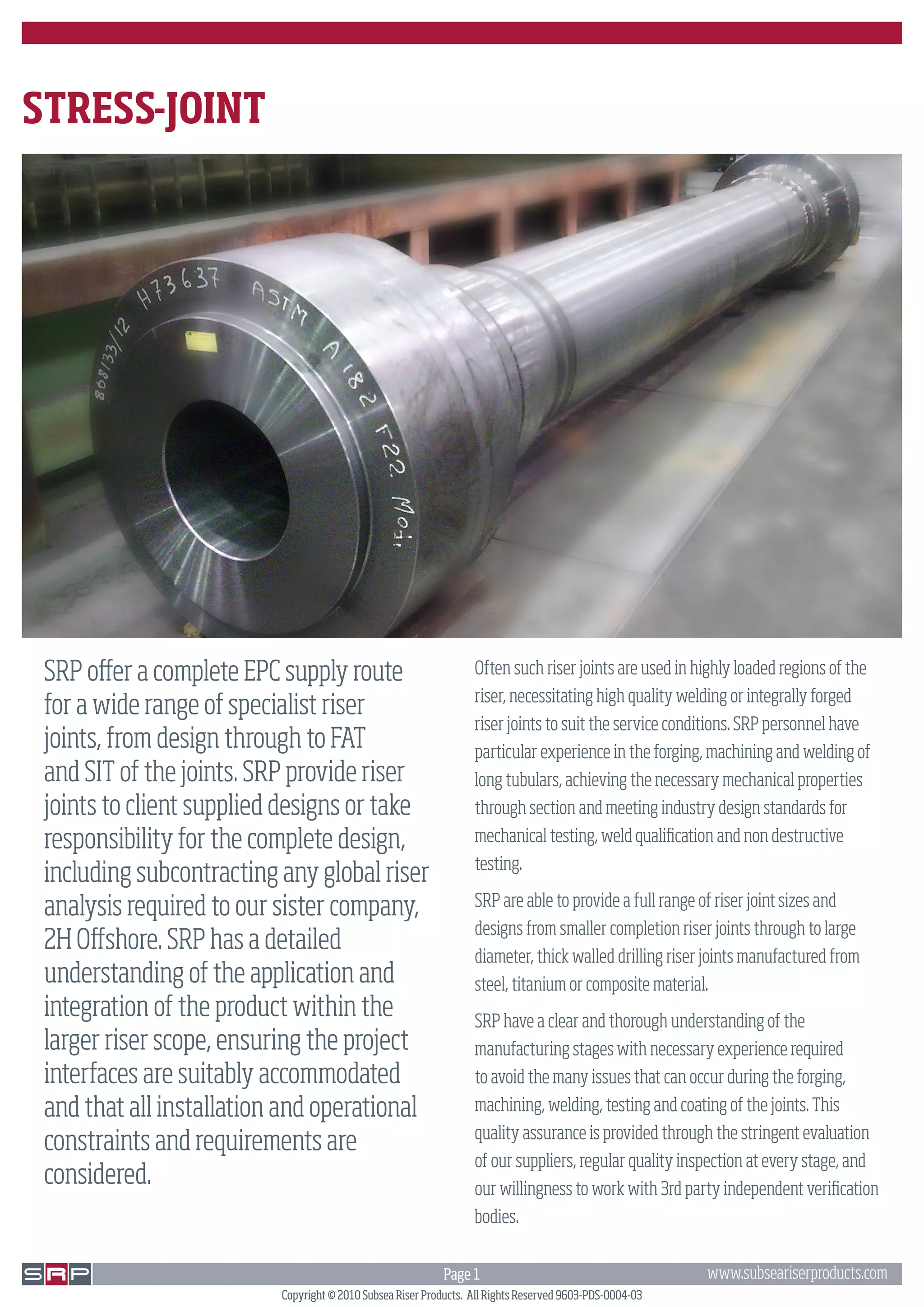

SRP offers design, manufacturing, and testing of specialized riser joints. They have experience forging, machining, and welding large tubular joints to meet industry standards. SRP can provide a full range of joint sizes from small completion joints to large diameter drilling riser joints made from steel, titanium, or composites. They ensure quality through supplier evaluation, inspection at all stages, and independent verification.