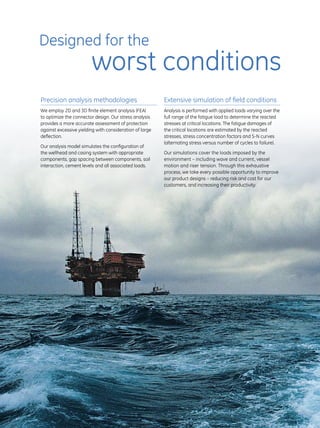

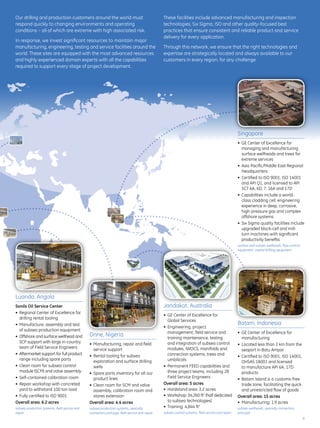

GE provides specialty connectors and pipe for oil and gas wells that are subjected to extreme pressures, temperatures, and environments. Their products are designed using advanced materials and testing to ensure reliability under harsh conditions. They have a global network of manufacturing and service facilities equipped to deliver customized solutions and support customers anywhere in the world.