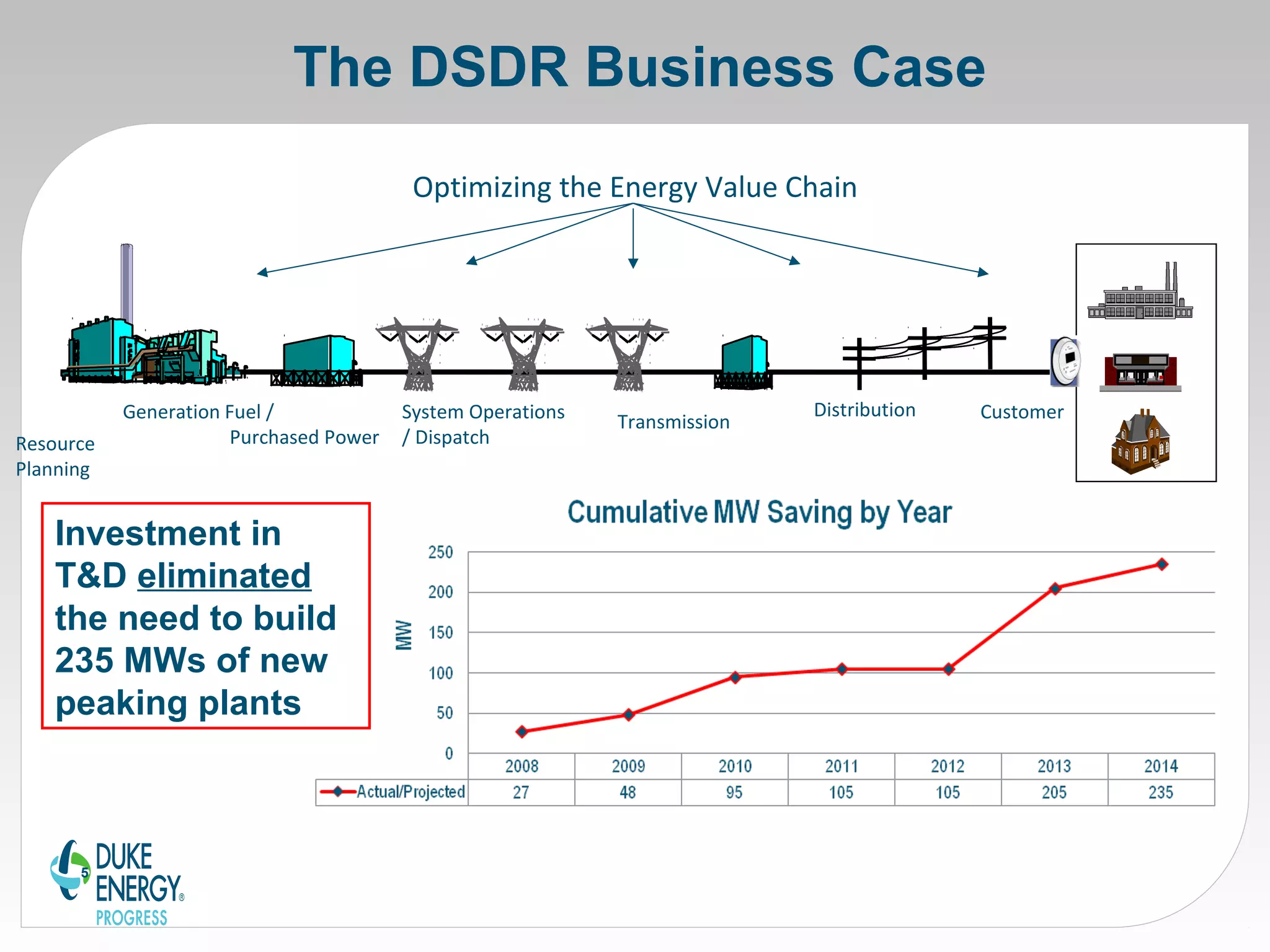

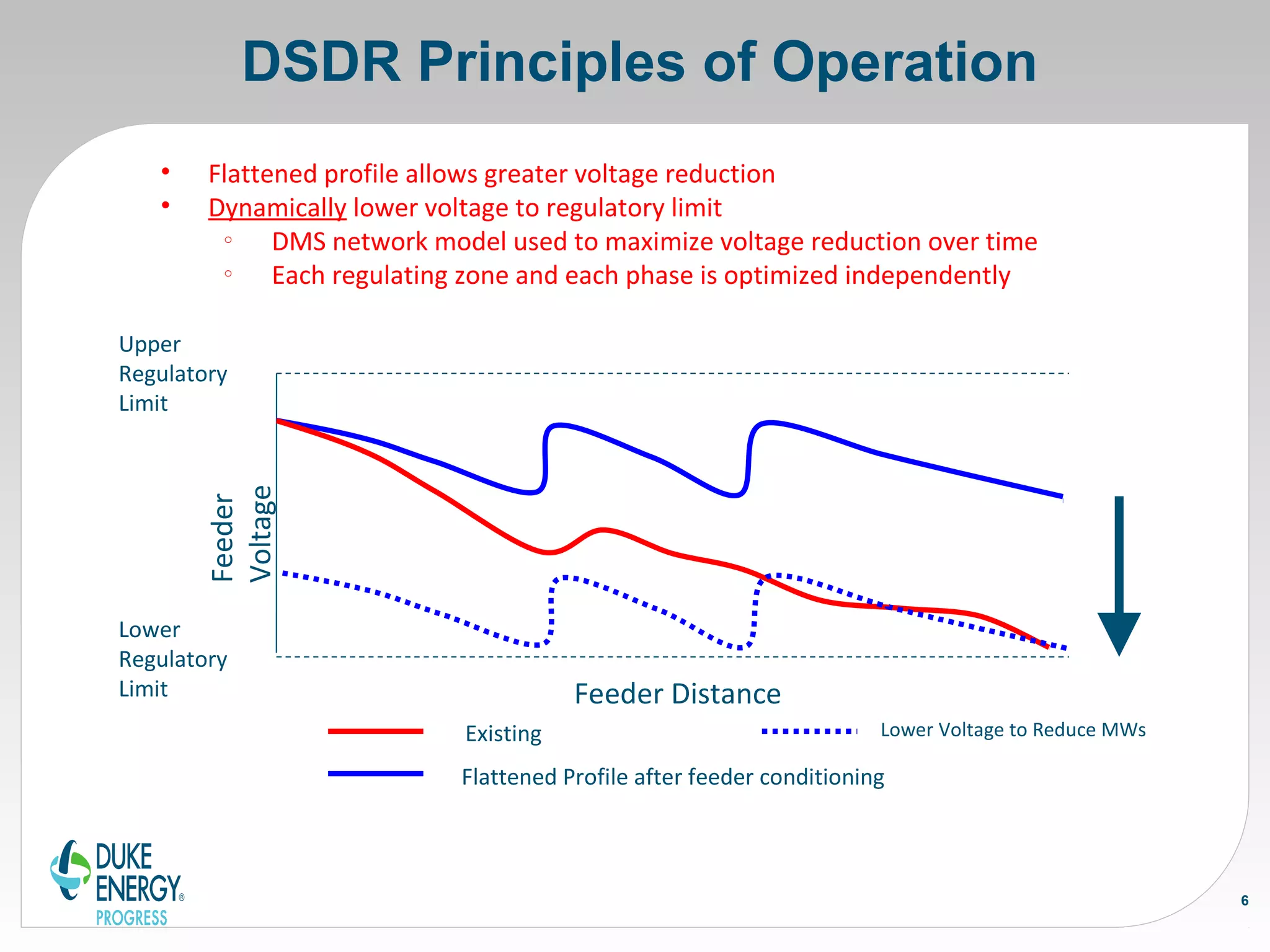

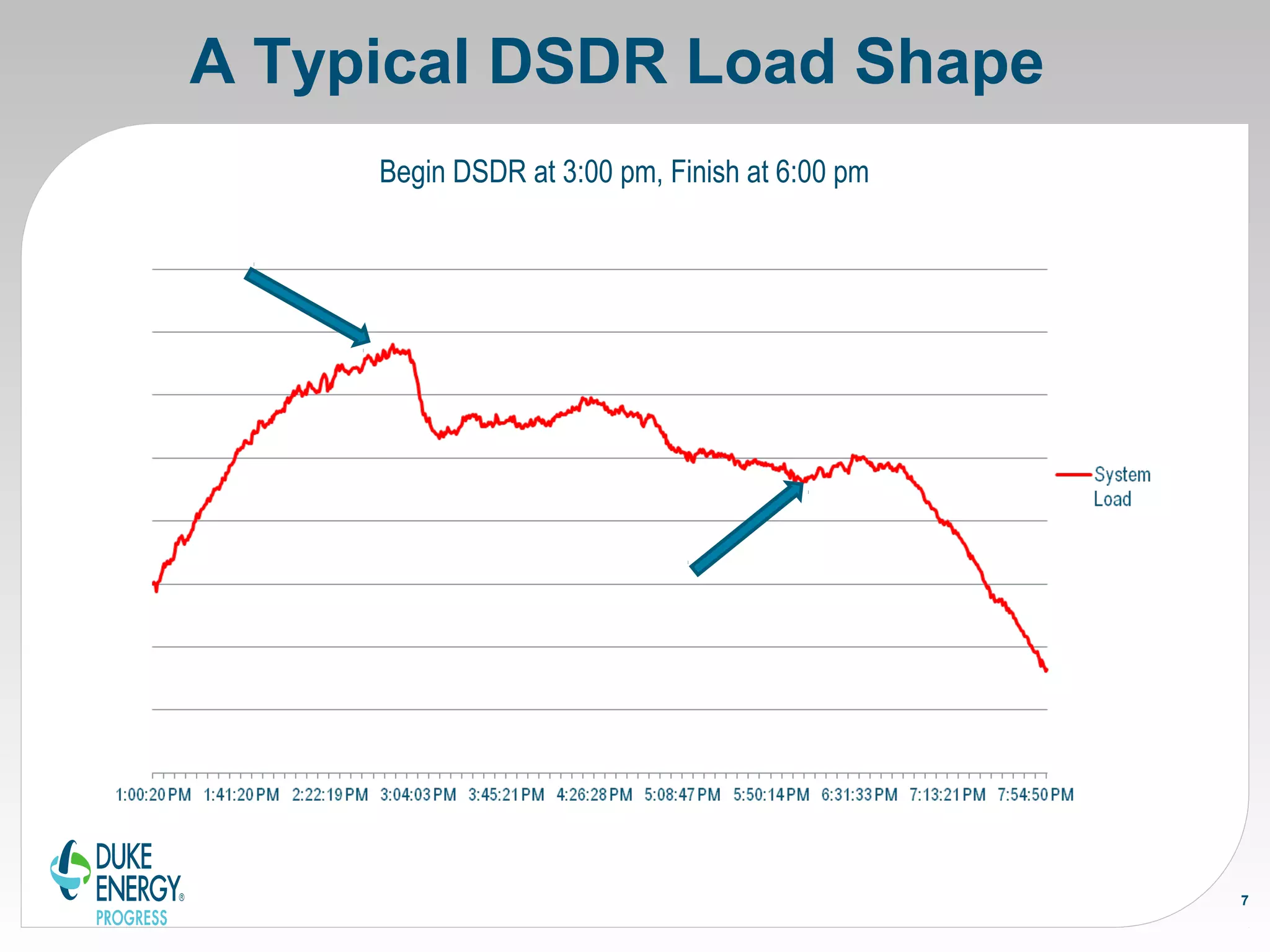

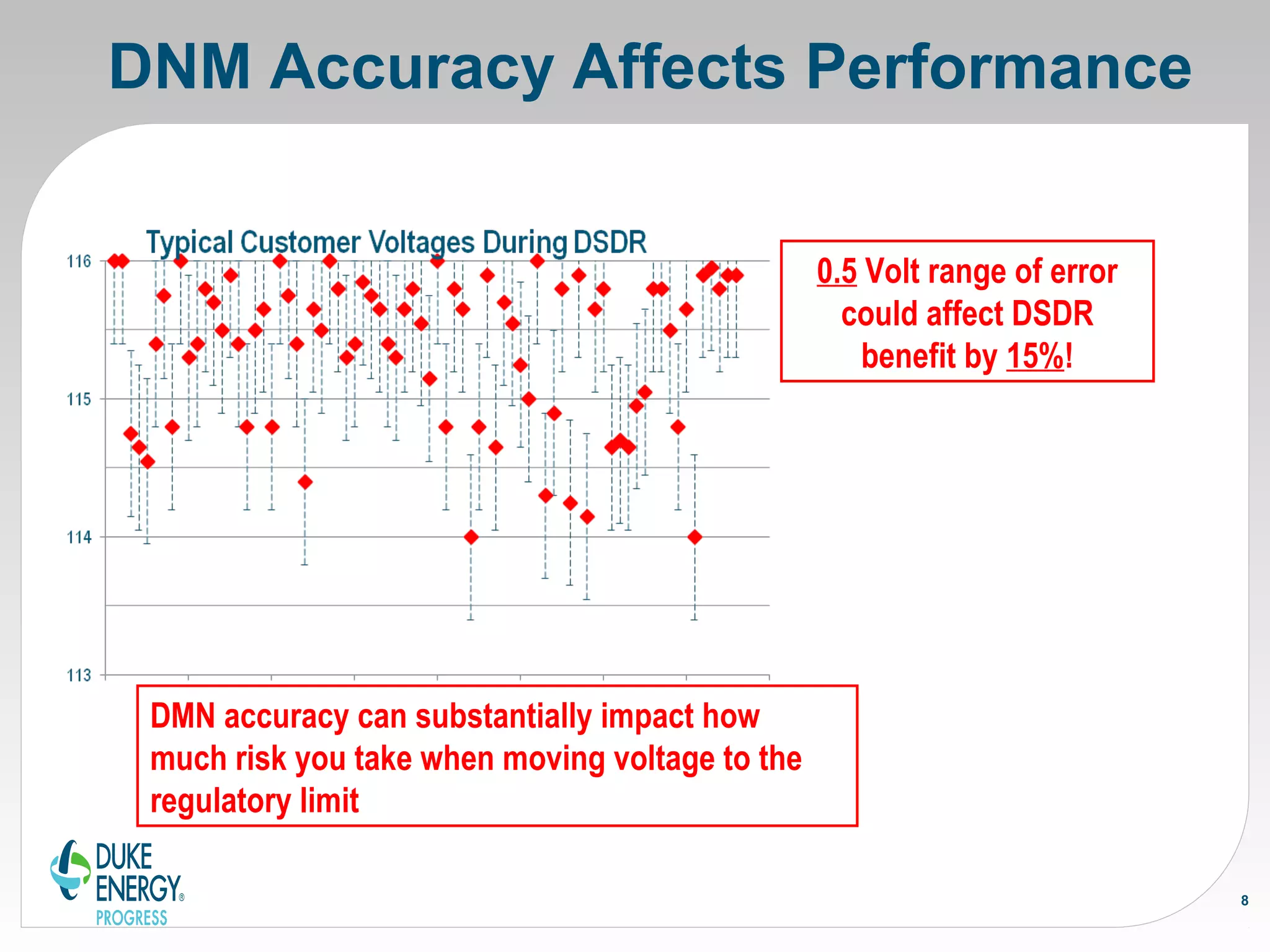

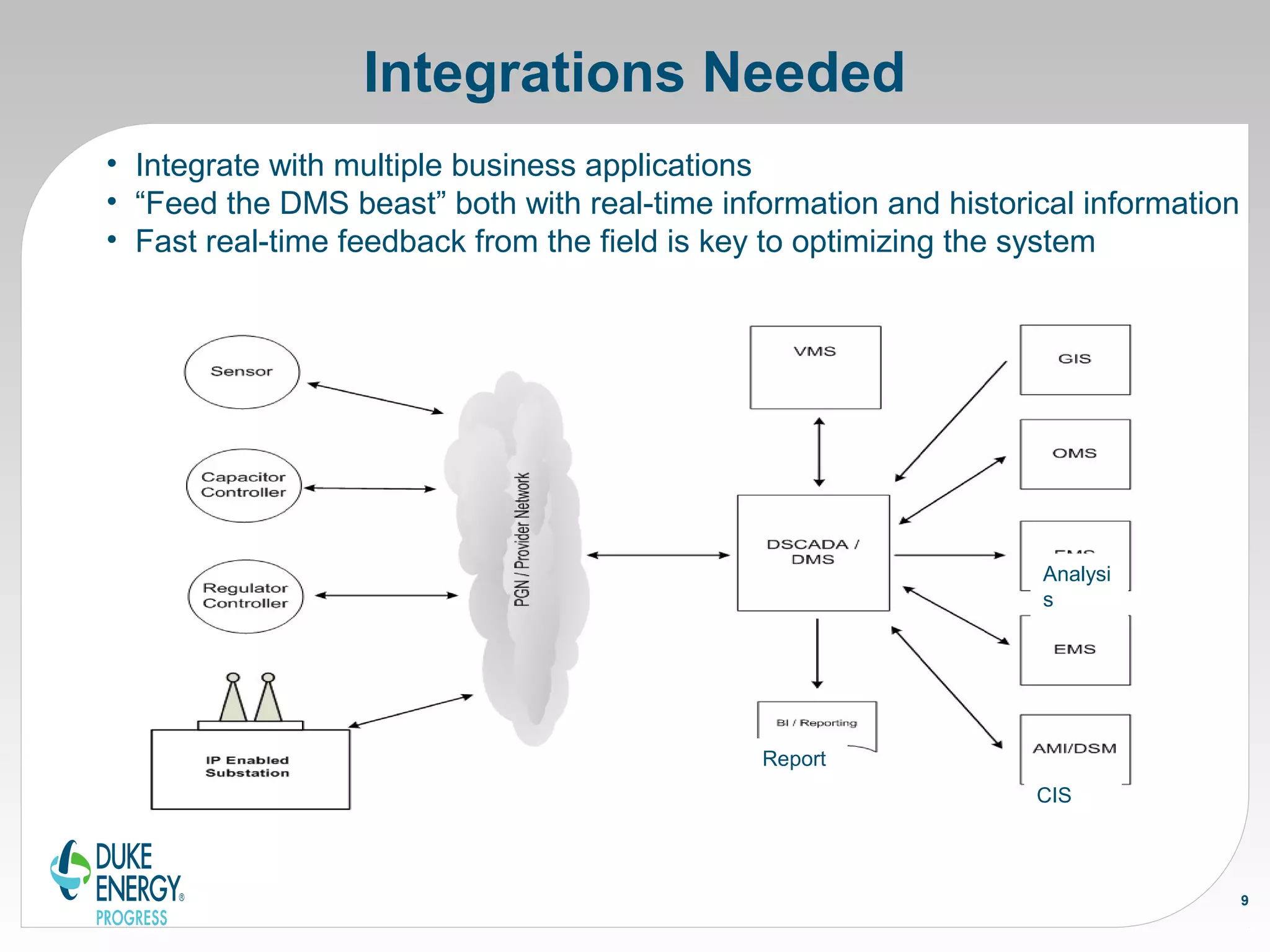

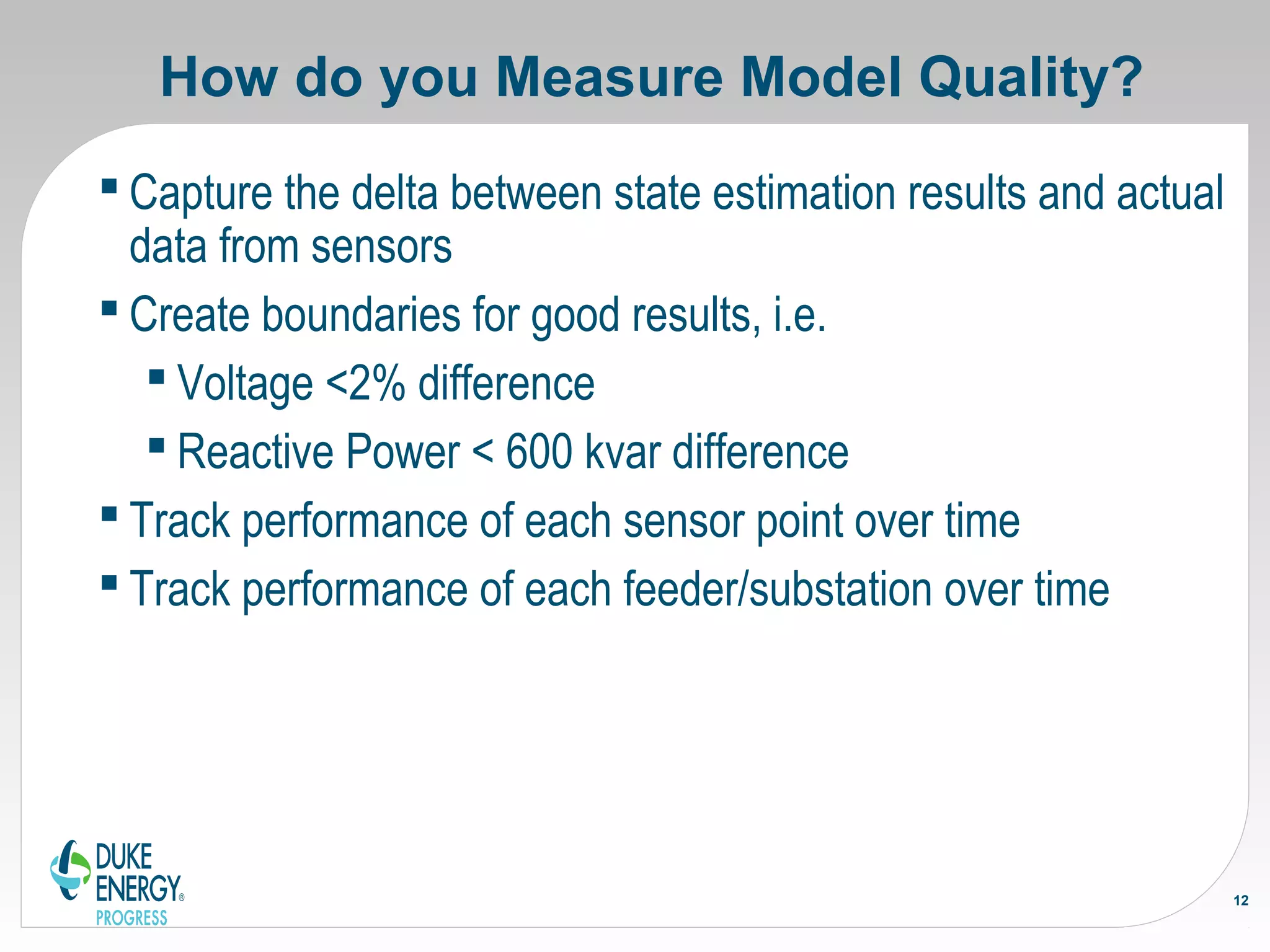

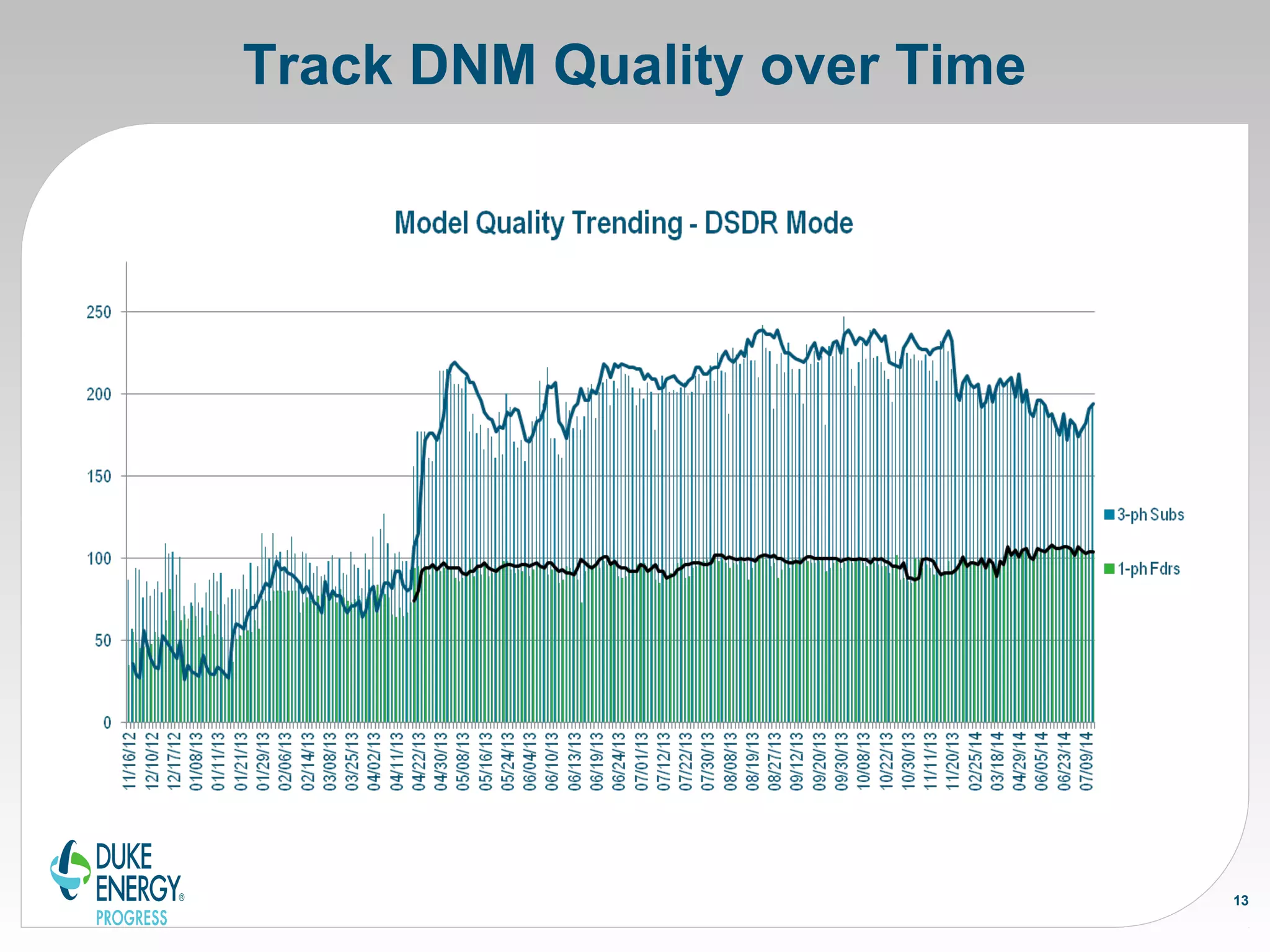

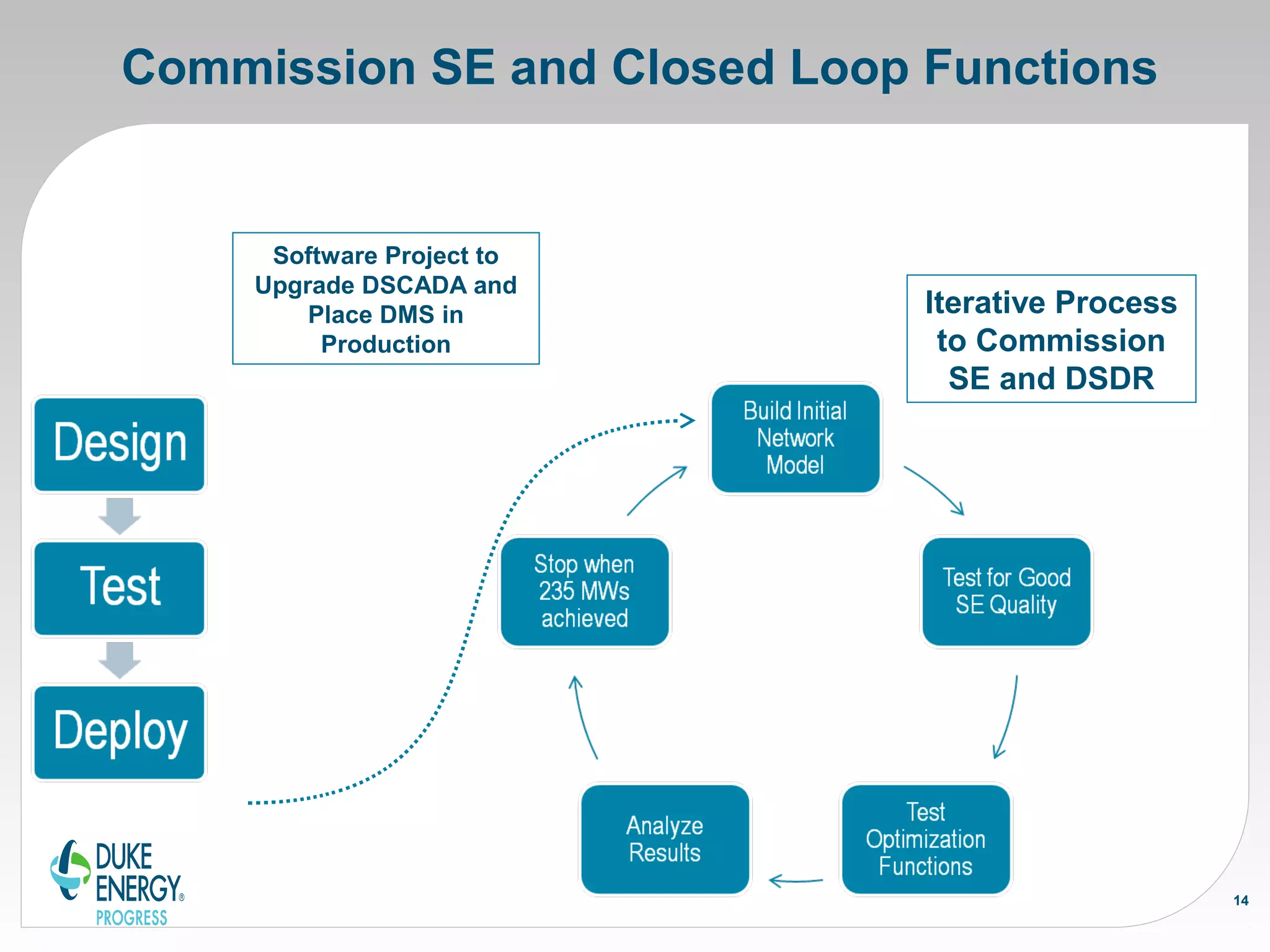

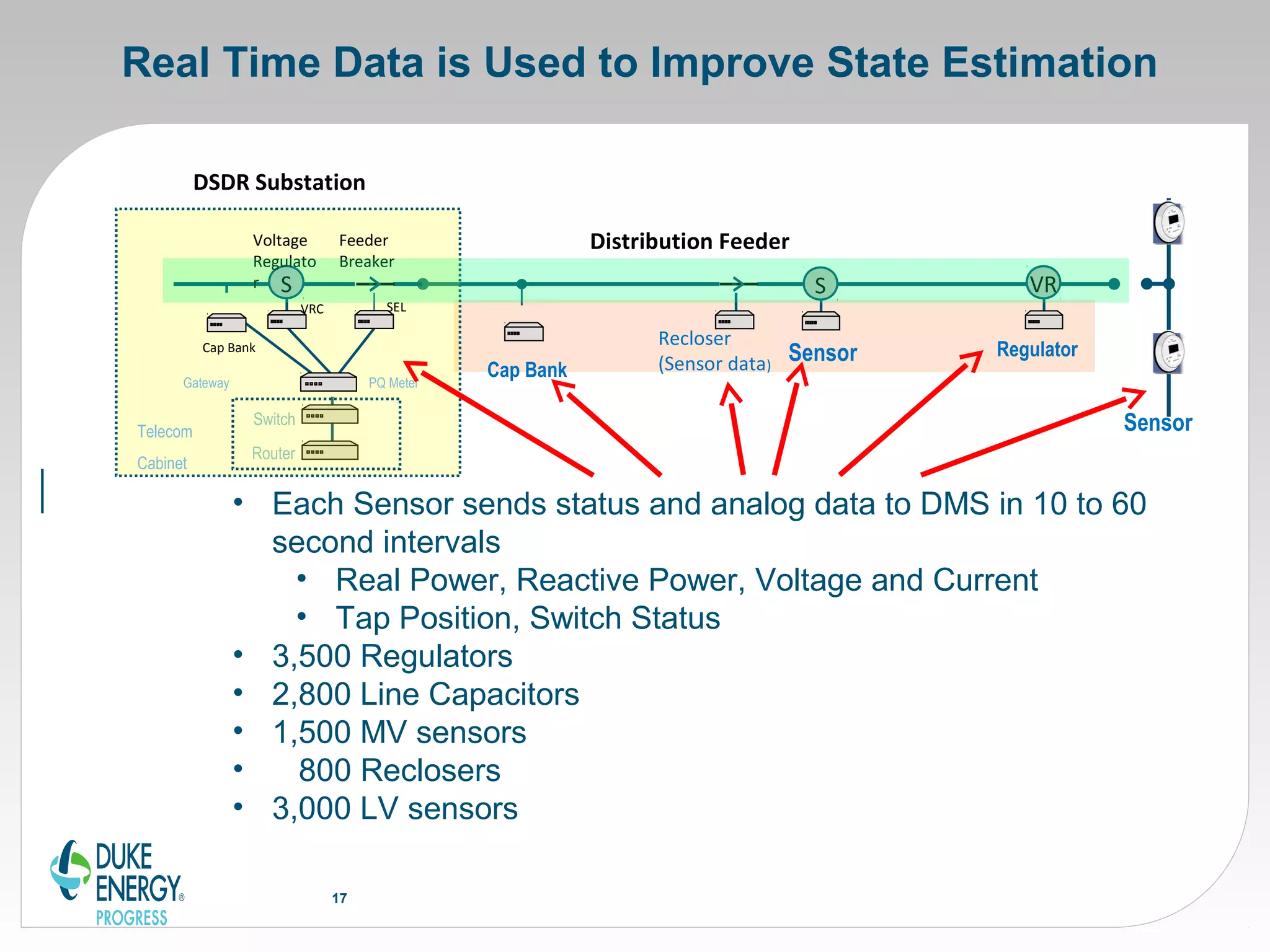

The document outlines essential strategies and considerations for implementing a Distribution Management System (DMS) network model, emphasizing the importance of accurate distribution network models (DNM) for optimizing results. It discusses the integration of DNM with various operational systems and the need for stakeholder engagement and change management. Key points include the impact of model accuracy on performance and the necessity of real-time data to enhance state estimation and system optimization.