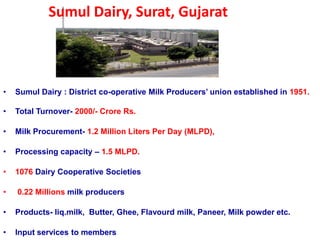

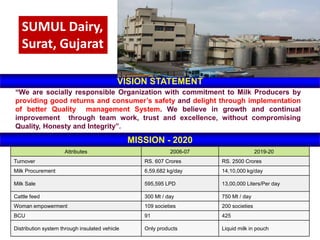

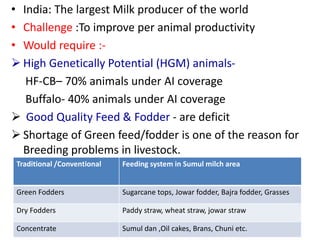

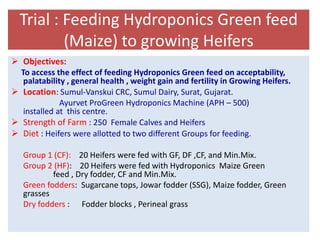

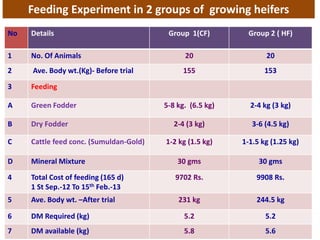

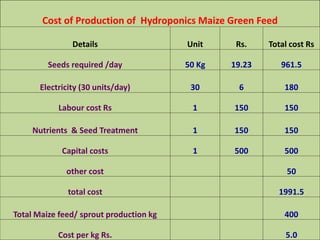

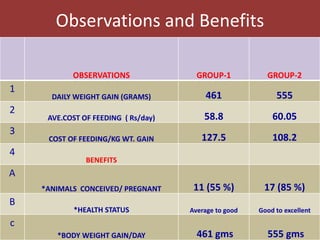

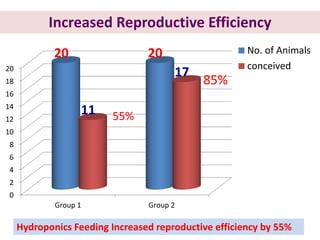

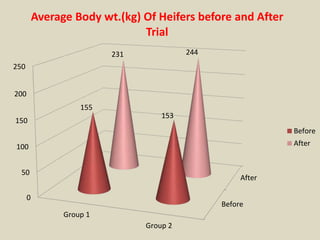

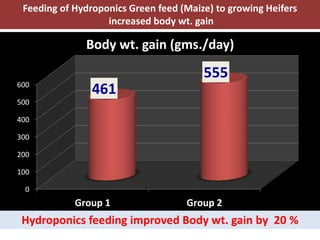

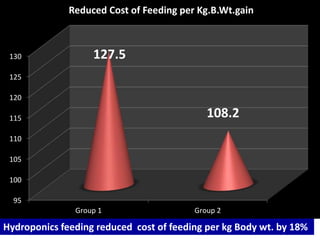

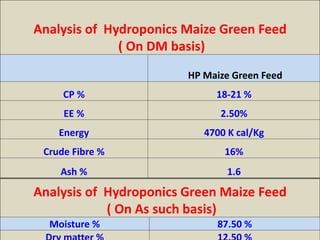

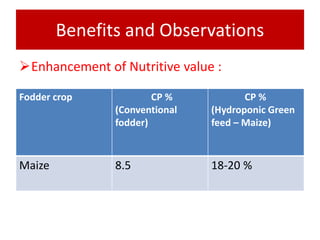

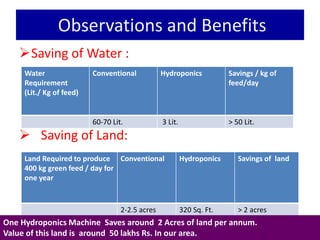

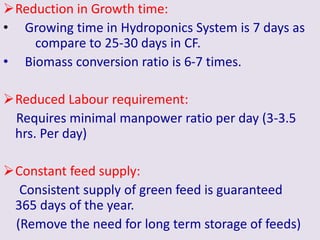

This document discusses a trial conducted by Sumul Dairy in Surat, India to evaluate the effects of feeding hydroponically grown maize to growing heifers. In the trial, 20 heifers were fed a conventional diet while another 20 were supplemented with hydroponic maize. The hydroponic feeding resulted in higher reproductive efficiency, daily weight gain, and lower cost of weight gain. It also reduced water and land usage compared to conventional fodder production. The hydroponic system improved the nutritional quality of the feed and allowed consistent supply with less labor.