This document describes a student project to build a mobile robot controlled by a mobile phone using DTMF tones. It provides background on the components used such as the DTMF decoder chip, microcontroller, motors, and includes schematics of the circuits used. The robot is designed so that pressing buttons on the mobile phone will generate DTMF tones that are received by the robot and used by the microcontroller to control the motors to move in different directions or turn.

![services for bomb disposal and fire fighting. Then came the remote controlled robot used in

television contests like Robot Wars, TechnoGamesand Mechanoids.

1.2. The 3 Laws of Robotics

Books, movies, stories, and other works of fiction help us think about the real world in new

ways. Science fiction has often been inspired by the future possibilities of robotics. However, the

relationship between science fiction and robotics is a two way street: science fiction affects the

field of robotics as well. Early in the history of robots, acclaimed writer Isaac Asimov became

concerned that humanity was unprepared for what he saw as the inevitable: robots becoming an

integral part of society in the future. In 1942, he created a 3-point code of conduct for the

st

century robots written about in his many books.

13

21

We call theseAsimov‟sLaws of Robotics:

1. A robot may not injure a human being or, through inaction, allow a human being to

come to harm.

2. A robot must obey the orders given it by human beings except where such orders

conflict with the first law.

3. A robot must protect its own existence as long as such protection does not conflict

with the First or Second law. [1]

1.3. Basic Parts of a Robot Vehicle

Basically a robot consists of the following basic, yet important parts –

A mechanical device, such as a wheeled platform, arm, or other construction, capable

of interacting with its environment.

Sensors on or around the device those are able to sense the environment and give

useful feedback to the device.

Systems that process sensory input in the context of the device's current situation and

instruct the device to perform actions in response to the situation.

In the manufacturing field, robot development has focused on engineering robotic arms that

perform manufacturing processes. In the space industry, robotics focuses on highly specialized,

one-of-kind planetary rovers. Unlike a highly automated manufacturing plant, a planetary rover](https://image.slidesharecdn.com/finalthesis-141026152131-conversion-gate01/85/driverless-Robot-car-controlled-using-GSM-16-320.jpg)

![Chapter 2

BACKGROUND STUDY

2.1. DTMF TECHNOLOGY

Dual-tone multi-frequency (DTMF) signaling is used for telephone signaling over the line in the

voice frequency band to the call switching center. The version of DTMF used for telephone tone

dialing is known by the trademarked term Touch-Tone, and is standardized by ITU-T

Recommendation Q.23. A different version is used for signaling internal to the telephone

network. DTMF is an example of a multi-frequency shift keying (MFSK) system. Today DTMF

is used for most call setup to the telephone exchange, at least in developed regions of the world.

2.2. History of DTMF

DTMF was developed at Bell Labs in order to allow dialing signals to dial long-distance

numbers, potentially over non wire links such as microwave links or satellites. Encoder/decoders

were added at the end offices that would convert the standard pulse signals into DTMF tones and

play them down the line to the remote end office. At the remote site another encoder/decoder

would decode the tones and perform pulse dialing

DTMF tones were also used by some cable television networks to signal the local cable company

to insert a local advertisement. These tones were often heard during a station ID preceding a

local ad inserts. Terrestrial television stations also used DTMF tones to shut off and turn on

remote transmitters. [2]

2.3. Keypad

When you press the buttons on the keypad, a connection is made that generates two tones at the

same time. A "Row" tone and a "Column" tone. These two tones identify the key you pressed to

any equipment you are controlling. If the keypad is on your phone, the telephone company's

"Central Office" equipment knows what numbers you are dialing by these tones, and will switch

your call accordingly. If you are using a DTMF keypad to remotely control equipment, the tones

can identify what unit you want to control, as well as which unique function you want it to

perform.

20](https://image.slidesharecdn.com/finalthesis-141026152131-conversion-gate01/85/driverless-Robot-car-controlled-using-GSM-23-320.jpg)

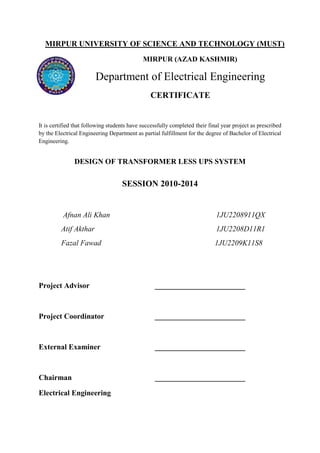

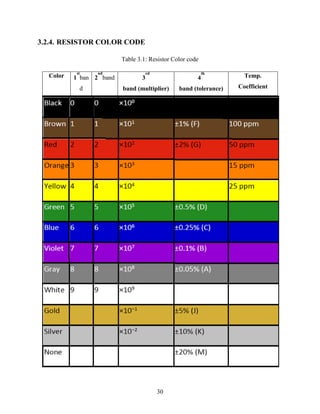

![Table 2.1 Keypad and respective DTMF frequencies

1 2 3 697 Hz

4 5 6 770 Hz

7 8 9 852 Hz

* 0 # 941 Hz

21

1209 Hz 1336 Hz 1477 Hz

When you press the digit 1 on the keypad, you generate the tones 1209 Hz and 697 Hz. pressing

the digit 2 will generate the tones 1336 Hz and 697 Hz. Sure, the tone 697 is the same for both

digits, but it take two tones to make a digit and the telephone company's equipment knows the

difference between the 1209 Hz that would complete the digit 1, and a 1336 Hz that completes a

digit 2.

2.4. DTMF Event Frequencies

Event Low frequency High frequency

Busy signal 480 -620 Hz

Dial tone 350 -440 Hz

Ring back tone 440 -480 Hz

The tone frequencies, as defined by the Precise Tone Plan, are selected such that harmonics and

Inter modulation products will not cause an unreliable signal. No frequency is a multiple of

another, the difference between any two frequencies does not equal any of the frequencies, and

the sum of any two frequencies does not equal any of the frequencies. The frequencies were

initially designed with a ratio of 21/19, which is slightly less than a whole tone. The frequencies

may not vary more than ±1.5% from their nominal frequency, or the switching center will ignore

the signal. The high frequencies may be the same volume or louder as the low frequencies when

sent across the line. The loudness difference between the high and low frequencies can be as

large as 3 decibels (dB) and is referred to as "twist". [3]](https://image.slidesharecdn.com/finalthesis-141026152131-conversion-gate01/85/driverless-Robot-car-controlled-using-GSM-24-320.jpg)

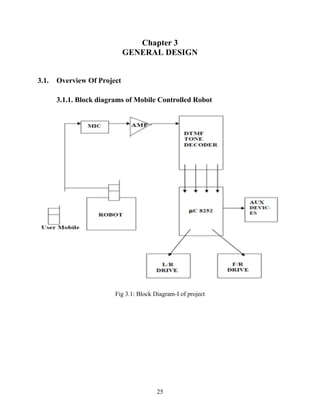

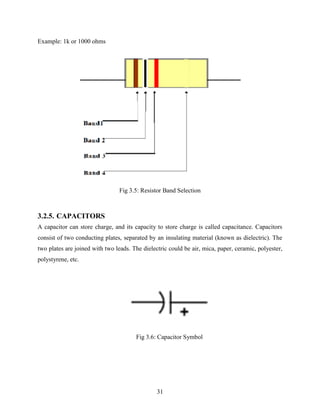

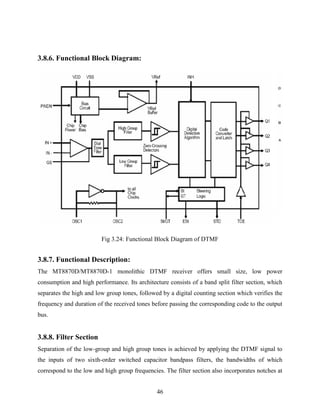

![Fig 3.2: Block Diagram-II of project

26

3.1.2. WORKING

Let key 2 be assigned for forward motion, key 4 for left, key 6 for right and key 8 for backward

motion. When forward motion is required, a call is established and key 2 is pressed. The DTMF

circuit picks up the frequency and determines that key 2 has been pressed. This is fed to the

micro controller in the form of an 8421 code i.e. 0010. The micro controller, which has been pre-programmed,

gives the signal to the motor to move forward. [4]

3.2. Components Used

It‟s a wireless controlled robot. In this we are utilizing the concept of GSM communication. It‟s

a wireless robot, which is controlled by our general mobile hand set. It works according to the

commands given by our mobile set. It uses two mobile sets. One at receiver end, which is

attached with the appliances (used as a receiver) and second at user end (which is used as](https://image.slidesharecdn.com/finalthesis-141026152131-conversion-gate01/85/driverless-Robot-car-controlled-using-GSM-29-320.jpg)

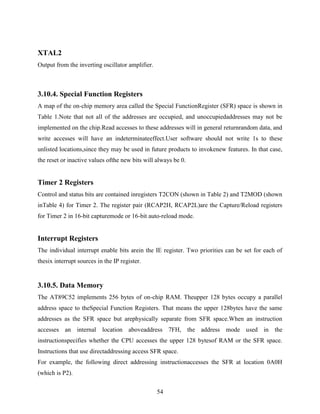

![350 and 440 Hz for exceptional dial tone rejection. Each filter output is followed by a single

order switched capacitor filter section, which smooth the signals prior to limiting. Limiting is

performed by high gain comparators, which are provided with hysteresis to prevent detection of

unwanted low-level signals. The outputs of the comparators provide full rail logic swings at the

frequencies of the incoming DTMF signals. [5]

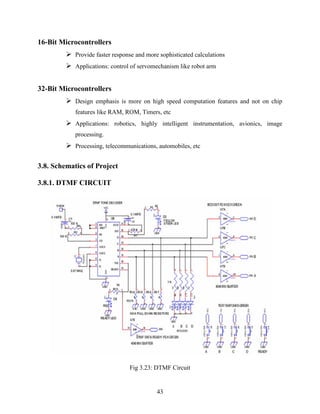

3.8.9. Decoder Section

Following the filter section is a decoder employing digital counting techniques to determine the

frequencies of the incoming tones and to verify that they correspond to standard DTMF

frequencies. A complex averaging algorithm protects against tone simulation by extraneous

signals such as voice while providing tolerance to small frequency deviations and variations.

This averaging algorithm has been developed to ensure an optimum combination of immunity to

talk-off and tolerance to the presence of interfering frequencies (third tones) and noise. When the

detector recognizes the presence of two valid tones (this is referred to as the “signal condition” in

some industry specifications) the “Early Steering” (ESt) output will go to an active state. Any

subsequent loss of signal condition will cause ESt to assume an inactive state

47

3.9. DC MOTOR DRIVE

Fig 3.25: DC-Motor Driver](https://image.slidesharecdn.com/finalthesis-141026152131-conversion-gate01/85/driverless-Robot-car-controlled-using-GSM-50-320.jpg)

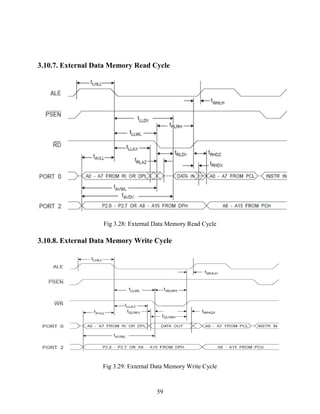

![3.9.3. Working Of DC Motor’s Steering Circuit

The circuit uses 7805 for a stabilized 5V dc supply with a ripple smoothening capacitor C1.

Input to the circuit is 12v dc. A power ON indicator led D1 is used with a current limiting

resistor R1. The steering mechanism has a built in dc motor rated at 5V, which consume

approximately 100mA current. When the motor is rotated in one direction for one second the

steering mechanism moves 2 wheels in one angle.

If the polarity is reversed to the motor the wheels move in other direction. The motor has a gear/

clutch mechanism built in, so, even if the power is given for greater than one second the clutch

slips & does damage the motor.

To operate this dc motor we require 2 SPDT relays, which can supply power of either polarity of

dc motor. When any one of them is energized see (relay k1 &k2) (in schematic) R3 & D4

(bicolor LED) one placed across the motor to indicate red/ green to show the clockwise/

anticlockwise rotation. Since the 2 relays provide opposite polarity voltage to the steering motor

only one relay at a time should be energized.

When both the relays are ON or OFF, no power is supplied to the motor. Relay energizing

indicator is also provided through an LED & back emf diodes (1N4148) are placed across relay

coils. As shown in schematic, left & right logic input connectors are used which can be

connected through two-way cables into the PCB. Two non-inverting buffers IC 4050 are used

with pull down resistors (100k) to keep the logic low.

When testing without the sensors two test switches are also provided to simulate the sensor

action, the output of 4050 is used to bias the transistors. No bias resistor is used, since the IC

4050 has built in 330 ohms resistors as per CMOS logic gate standards. [7]

49

3.10. AT89C52 Microcontroller

3.10.1. Description

The AT89C52 is a low-power, high-performance CMOS 8-bit microcomputer with 8Kbytes of

Flash programmable and erasable read only memory (PEROM). The deviceis manufactured

using Atmel‟s high density nonvolatile memory technology and iscompatible with the industry

standard 80C51 and 80C52 instruction set and pinout.The on-chip Flash allows the program](https://image.slidesharecdn.com/finalthesis-141026152131-conversion-gate01/85/driverless-Robot-car-controlled-using-GSM-52-320.jpg)

![Program Design and Working

67

4.1. Working of GSM Robot

Fig 4.1: Block Diagram

Radio control (often abbreviated to R/C or simply RC) is the use of radio signals to remotely

control device. The term is used frequently to refer to the control of model vehicles from a hand-held

radio transmitter. Industrial, military, and scientific research organizations make use of

radio-controlled vehicles as well. A remote control vehicle (RCV) is defined as any mobile

device that is controlled by a means that does not restrict its motion with an origin external to the

device. This is often a radio control device, cable between control and vehicle, or an infrared

controller. A RCV is always controlled by a human and takes no positive action autonomously.

One of the key technologies which underpin this field is that of remote vehicle control. It is vital

that a vehicle should be capable of proceeding accurately to a target area manoeuvring within

that area to fulfil its mission and returning equally accurately and safely to base. This project

includes a robotic car consisting of a cell phone, DTMF decoder and microcontroller. The

transmitter is a handheld mobile phone. [6]](https://image.slidesharecdn.com/finalthesis-141026152131-conversion-gate01/85/driverless-Robot-car-controlled-using-GSM-70-320.jpg)

![An opto-isolator contains a source (emitter) of light, almost always a near infrared light-emitting

diode (LED), that converts electrical input signal into light, a closed optical channel (also called

dielectrically channel), and a photo sensor, which detects incoming light and either generates

electric energy directly.[8]

72

4.4. Working

PC 817 is a 4 pin opto coupler as shown above. A series resistance of 470 ohm is used to limit

the voltage across the diode. +5V power supply is connected to the first pin of IC, which is the

anode pin diode. 2

nd

pin is connected to the port of microcontroller. When the second pin is low

then we get low output, when the input to 2

nd

pin high we get high voltage the output. Thus we

isolate the voltage having the same logic level.

4.5. H-BRIDGE CIRCUIT

An H bridge is an electronic circuit which enables a voltage to be applied across aload in either

direction. These circuits are often used in robotics and other applications to allow DC motors to

run forwards and backwards.

Fig 4.7: H-Bridge circuit

The term H bridgeis derived from the typical graphical representation of such a circuit. An H

bridge is built with four switches (solid-state or mechanical).

When the switches S1 and S4 are closed (and S2 and S3 are open) a positive voltage will be

applied across the motor. By opening S1 and S4 switches and closing S2 and S3 switches, this

voltage is reversed, allowing reverse operation of the motor.](https://image.slidesharecdn.com/finalthesis-141026152131-conversion-gate01/85/driverless-Robot-car-controlled-using-GSM-75-320.jpg)

![REFERENCES

[1] The Three Laws of Robotics, “Asimov's Laws”, available on-line at

http://en.wikipedia.org/wiki/Three_Laws_of_Robotics

[2] Schenker, L (1960), "Pushbutton Calling with a Two-Group Voice-Frequency Code", The

Bell system technical journal, Vol. 39, no. 1, pp. 235–255, ISSN 0005-8580, July 2013.

[3] Ahmed M and J.K.Pathan,“3 G based industrial automation using GSM

communication” ,International Journal of Research in Environmental Science and

Technology, Vol. 1, no. 1, pp 16-21, June 2011.

[4] M. Ali Yousuf, R. Montúfar Chaveznava, and V. de la CuevaCueva Hernández, “Hernández

Current Developments in Technology-Assisted Education”, Robotic projects to

enhance student participation, motivation and learning, , pp 922-952, July 2008.

[5] Robert Siwy, "Generation and Recognition of DTMF Signals with the Microcontroller

MSP430", Texas Instruments Deutschland, October 2005.

[6] DTMF Tester, “Electronics For You” Magazine , Edition” (June 2003)

[7] Cell phone operated land rover robot For You, “ Magazine, Edition” (July 2008)

[8] Liu, Simon & Silverman “Cell phone based land rover”, Mark. available on-line at:

http://www.instructables.com/id/Cellphone-operated-Robot/ ,Jan 2013.

78](https://image.slidesharecdn.com/finalthesis-141026152131-conversion-gate01/85/driverless-Robot-car-controlled-using-GSM-81-320.jpg)