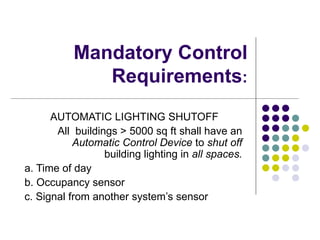

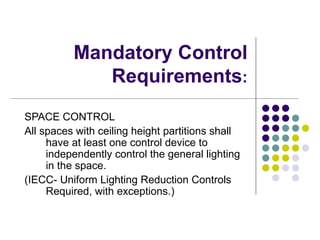

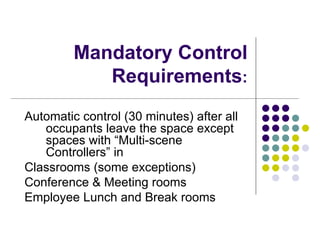

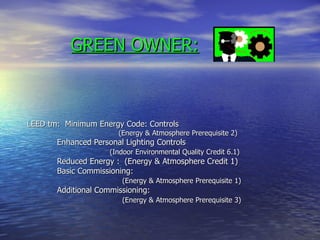

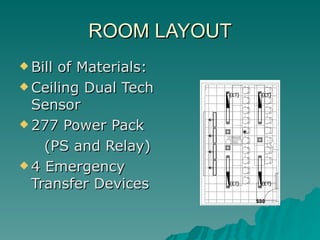

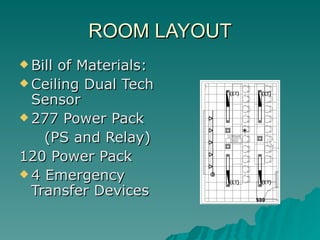

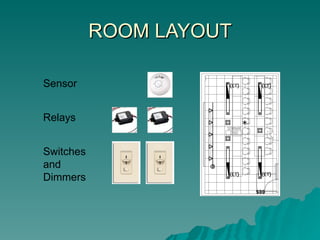

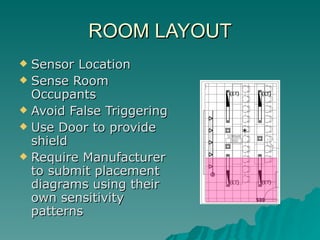

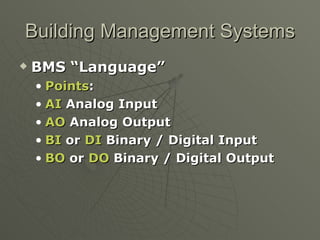

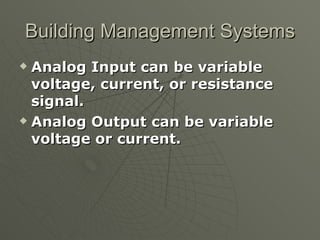

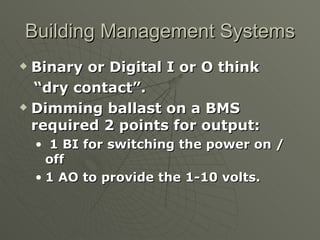

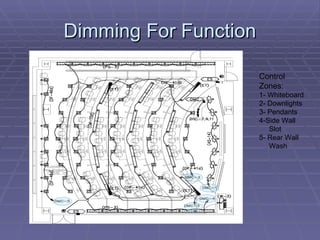

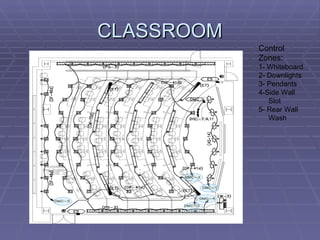

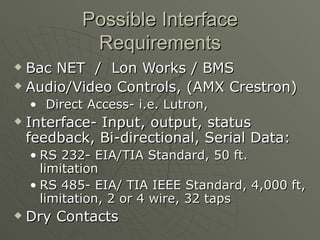

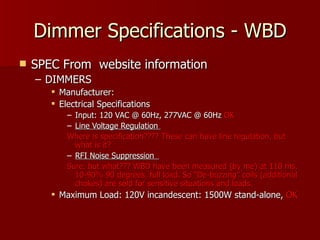

This document provides information on advanced lighting controls and mandatory control requirements for lighting systems. It discusses why lighting control is important, including user needs, legal codes, and energy efficiency. The document outlines mandatory control requirements from energy codes, including automatic shutoff controls, space controls, and occupancy sensor requirements. It also discusses control requirements for exterior lighting, additional controls for special applications, and considerations for green building projects. The document provides an overview of passive and active lighting control strategies and examples of sensor specifications and room layout diagrams.