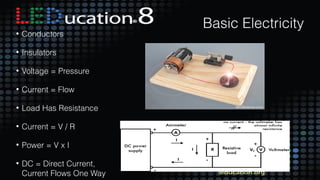

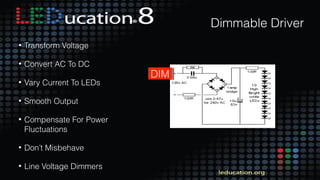

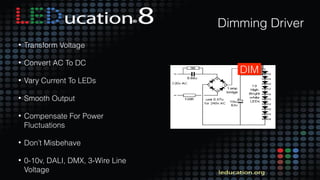

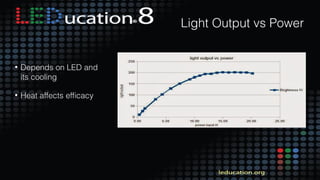

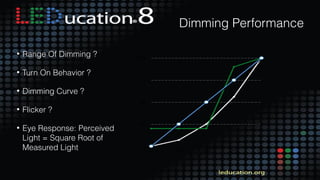

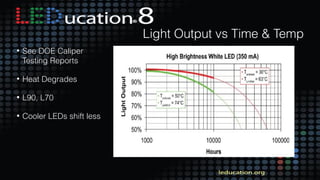

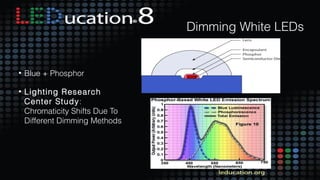

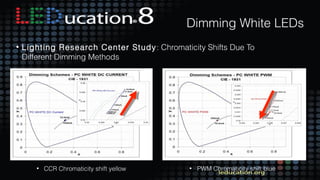

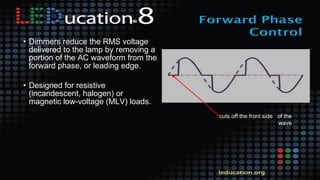

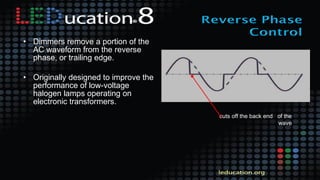

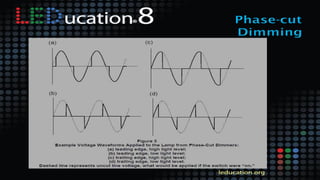

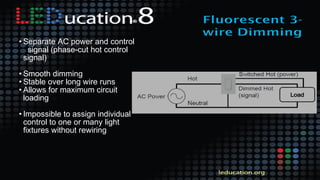

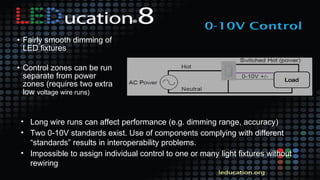

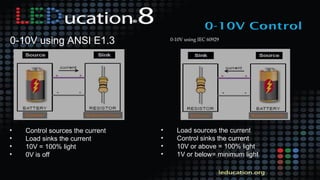

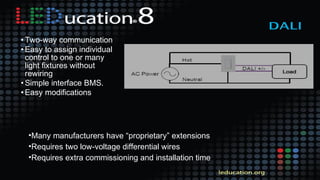

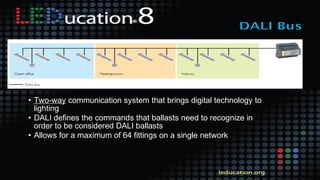

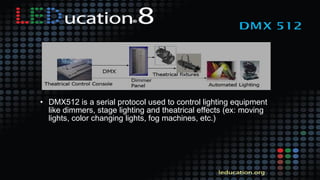

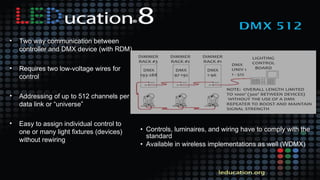

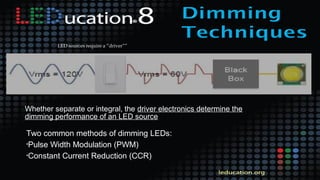

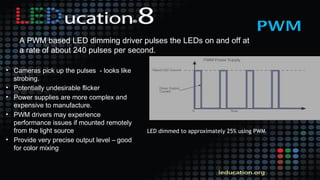

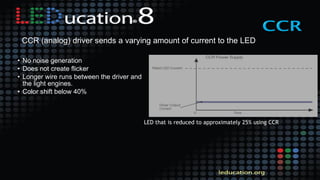

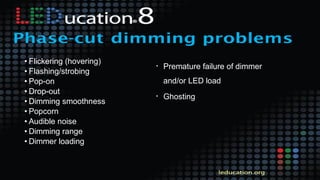

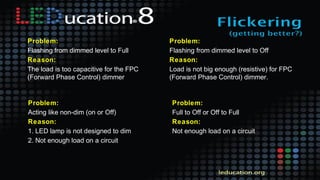

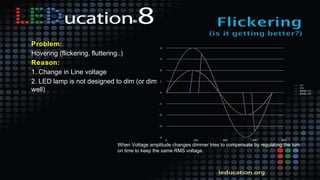

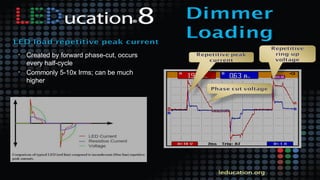

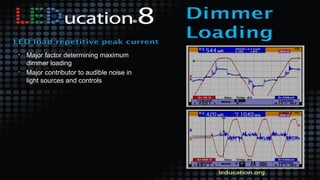

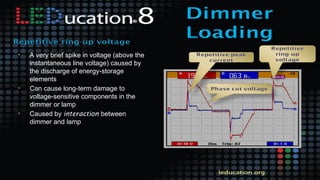

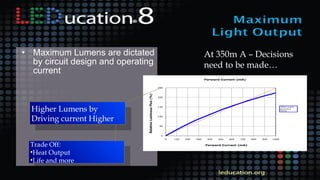

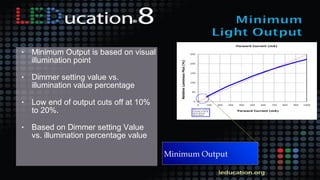

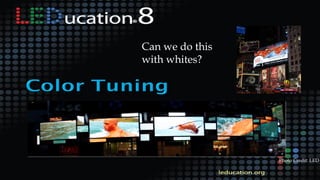

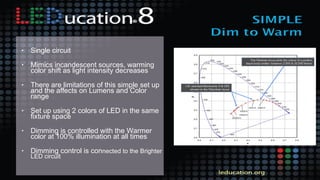

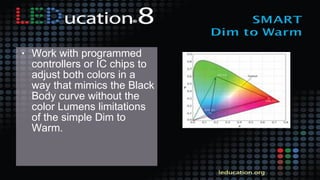

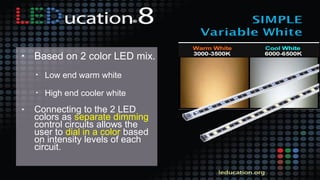

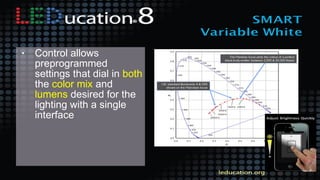

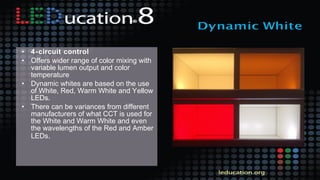

This document provides an outline for a presentation on LED dimming and control. It discusses how LEDs work, different dimming methods including phase control, 0-10V, DALI and DMX, and how dimming affects color and performance. It also covers visual effects of dimming LEDs, controlling color temperature, and automated control options. The presentation is intended to explain LED dimming challenges and best practices to integrators and designers.