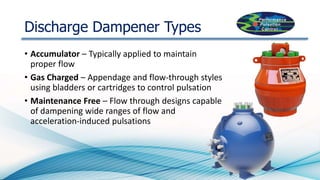

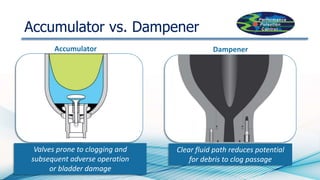

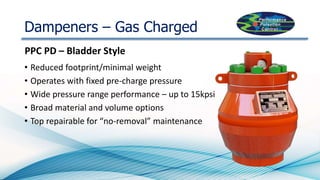

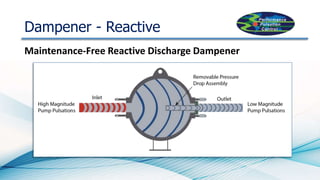

The document discusses the importance of discharge dampeners in pump and piping systems to control vibrations and prevent equipment failure. It highlights various types of dampeners, including maintenance-free options, and emphasizes their benefits such as enhanced safety, increased system life, and reduced operating costs. The document also mentions the company's commitment to performance, customization, and providing a worry-free customer experience.