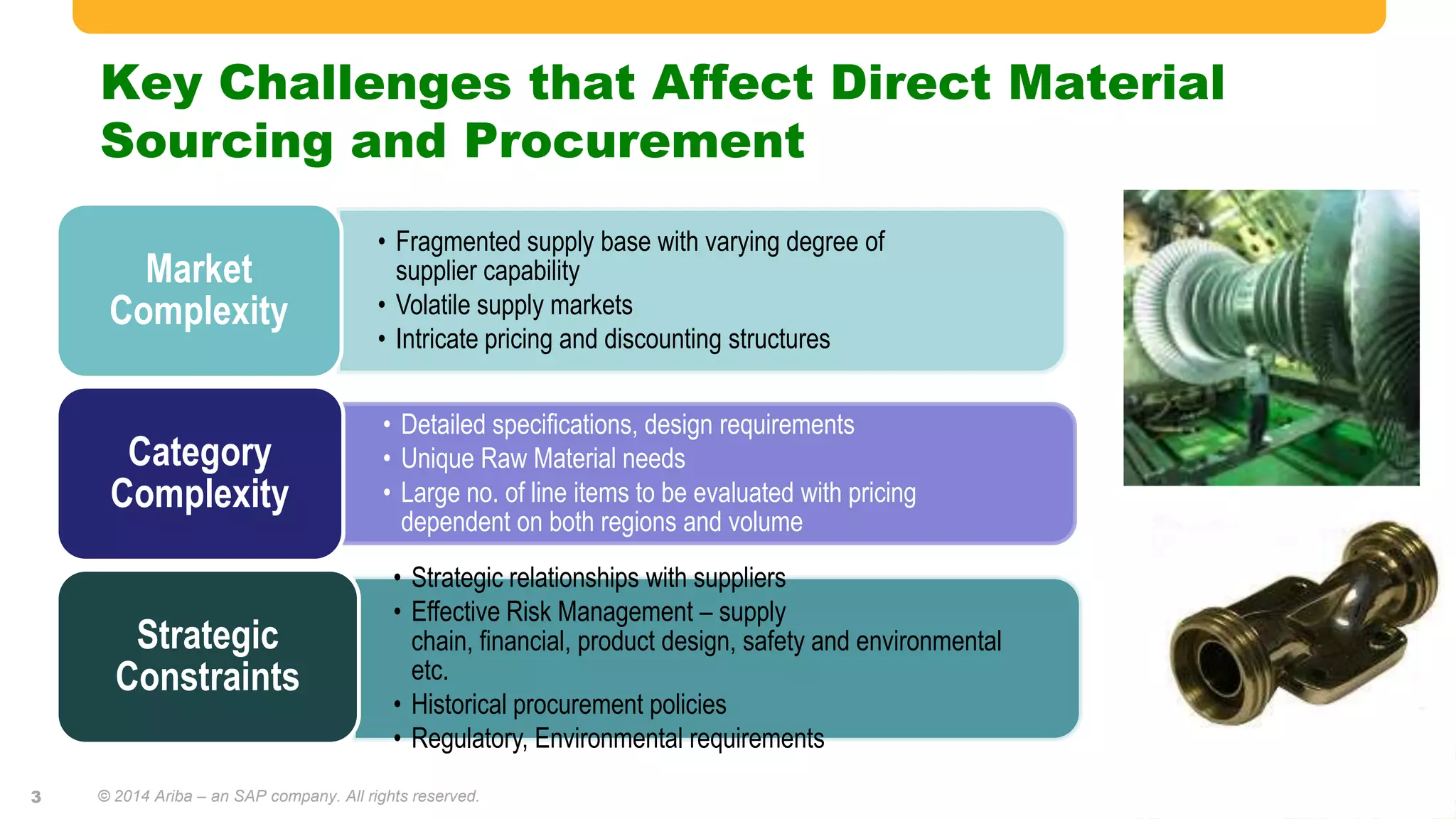

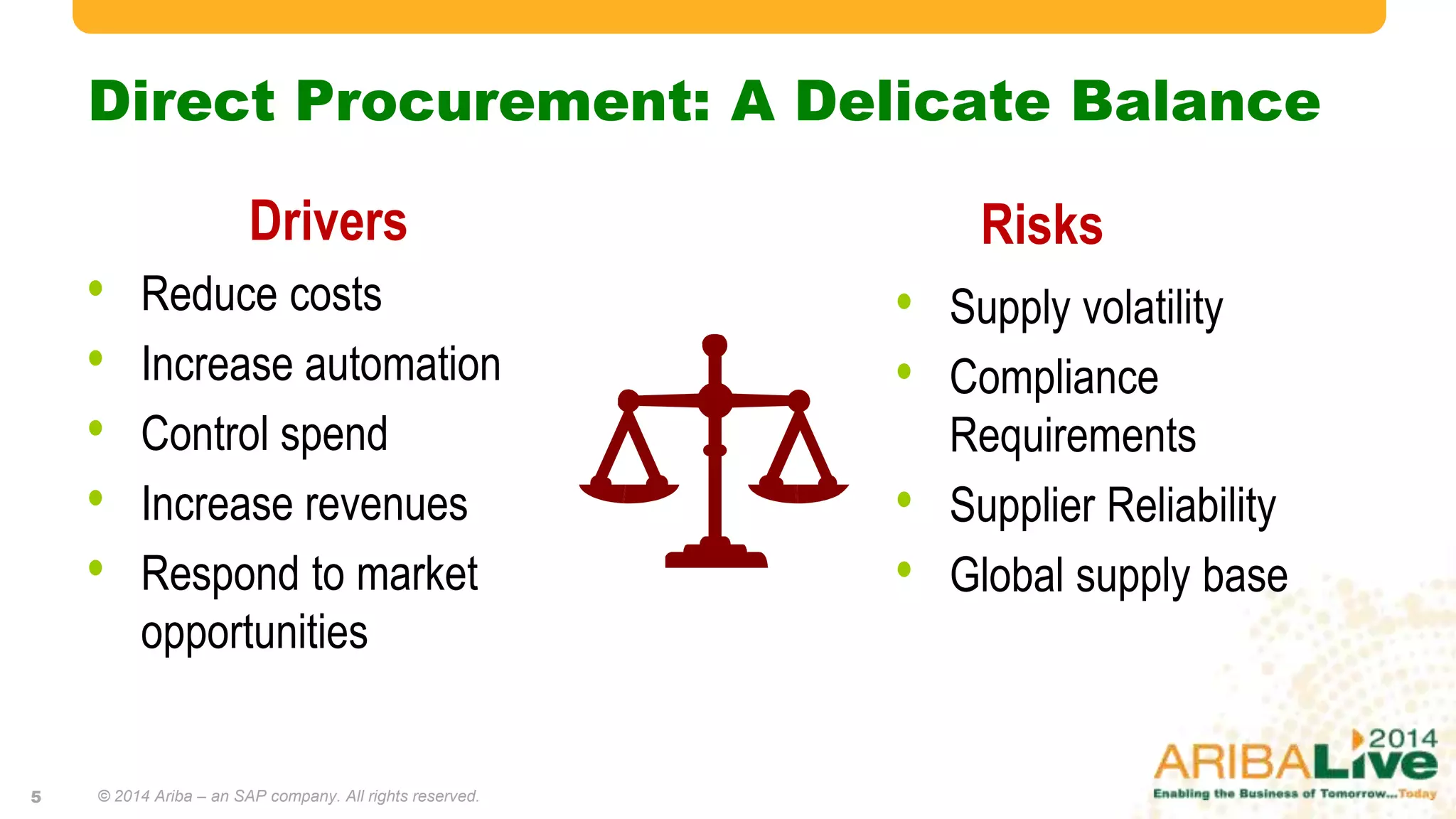

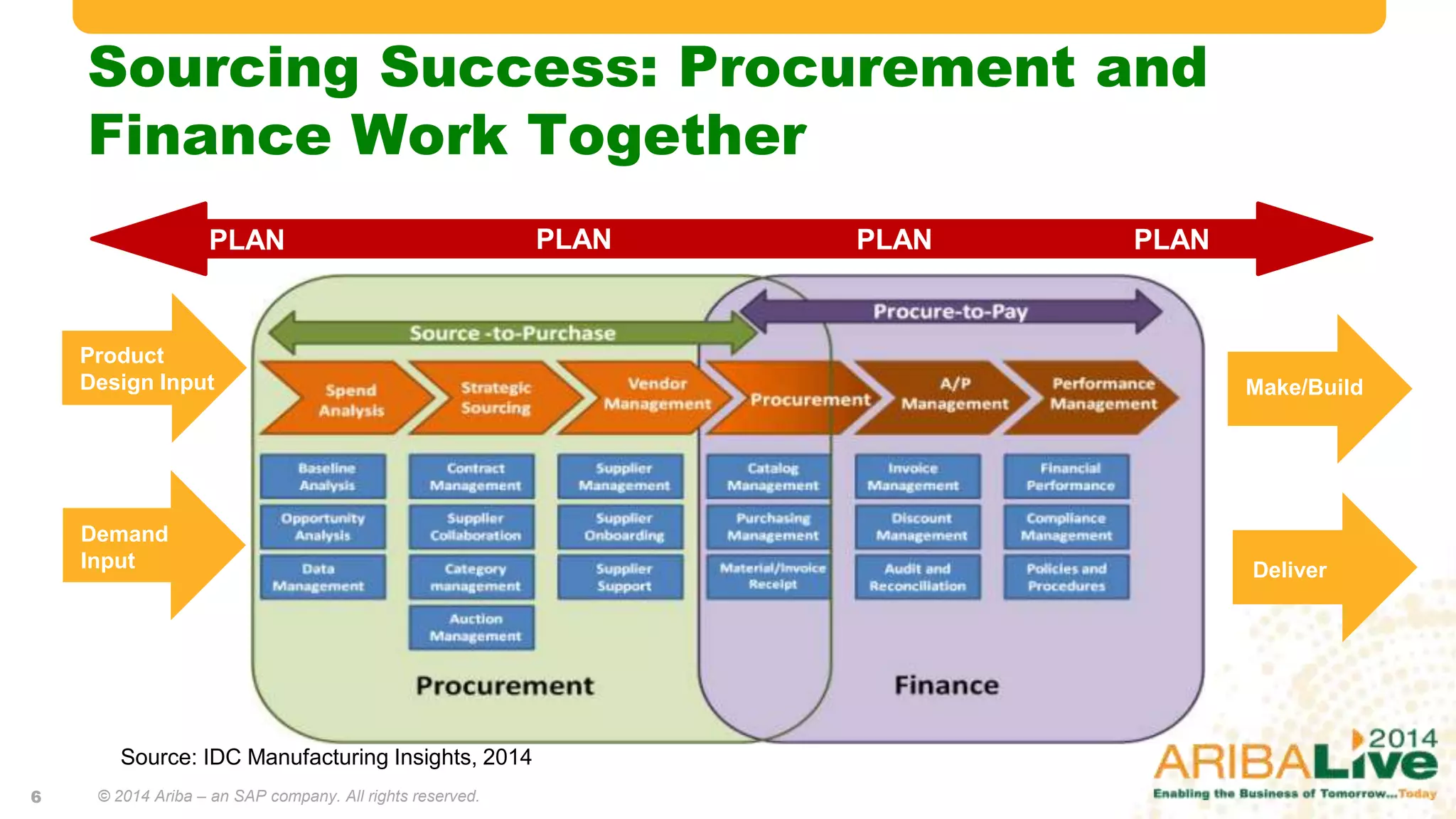

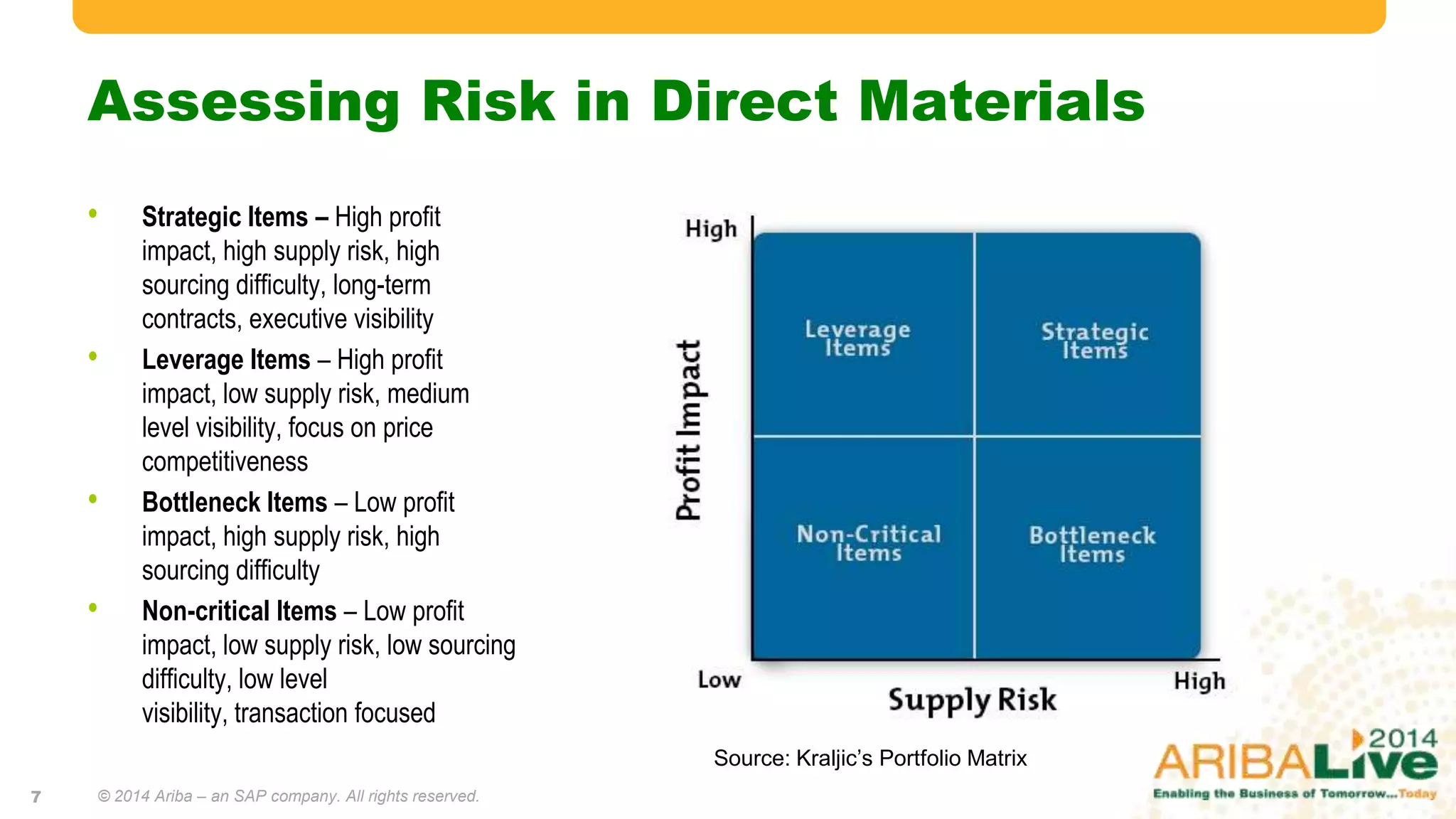

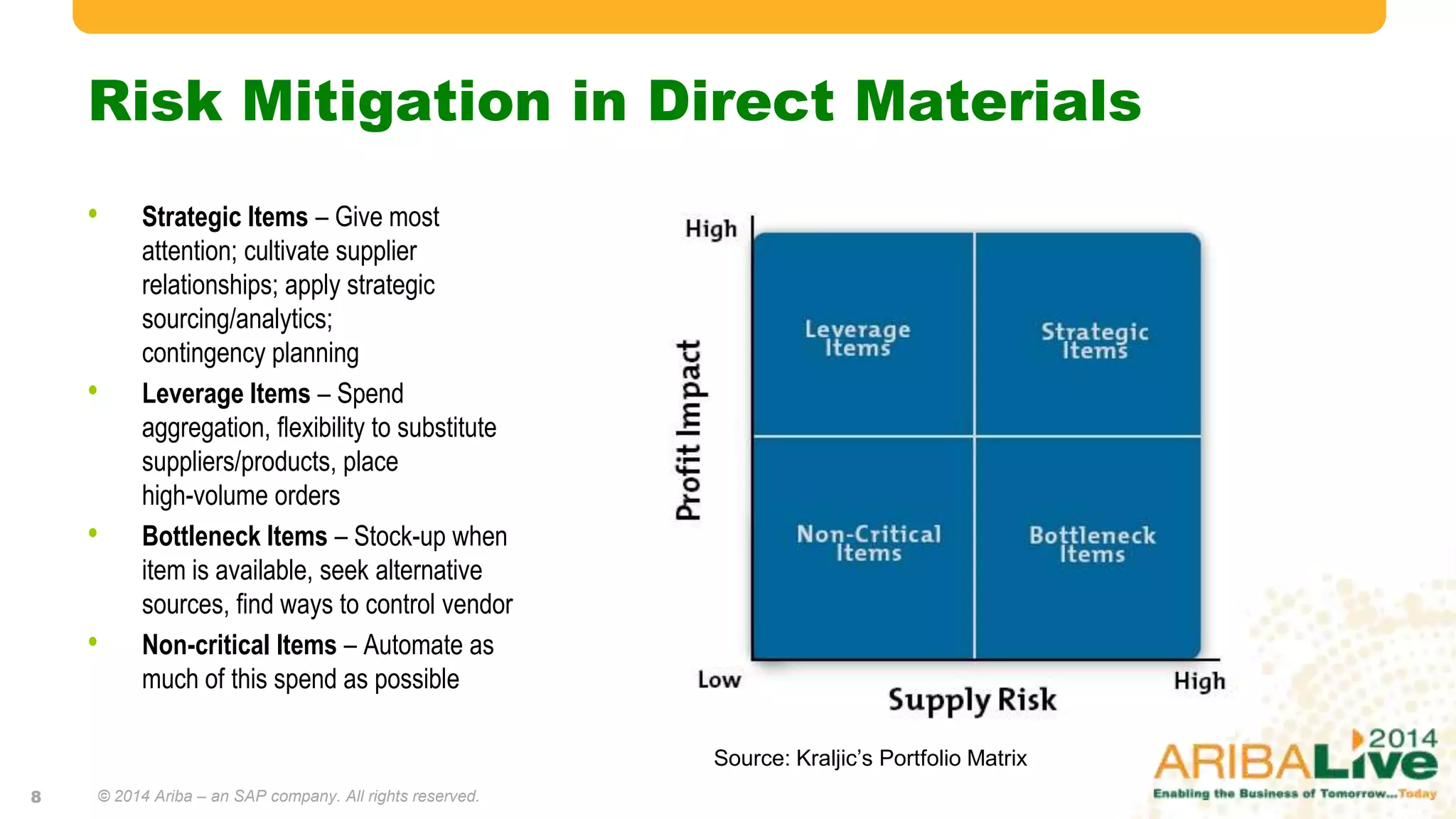

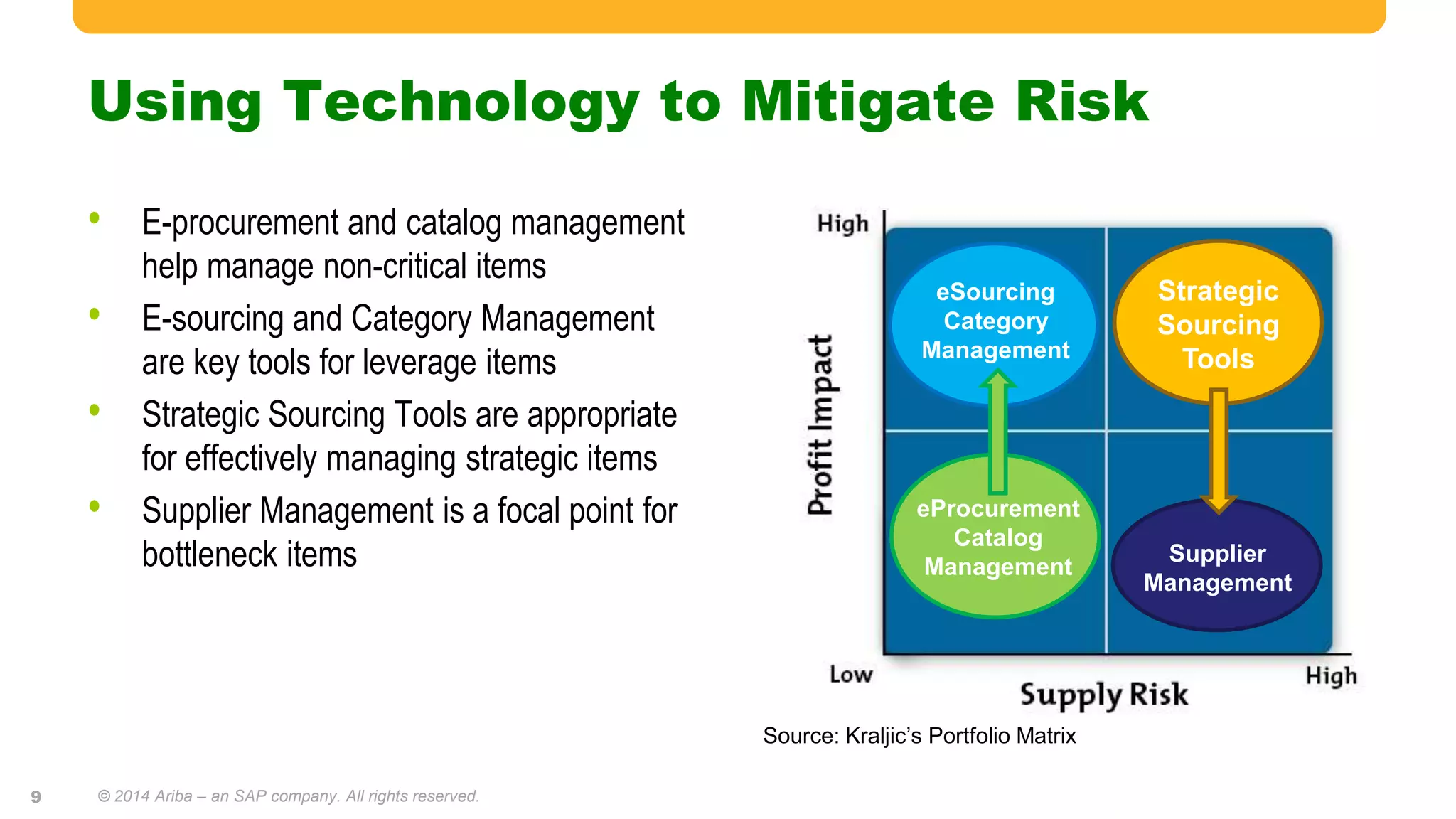

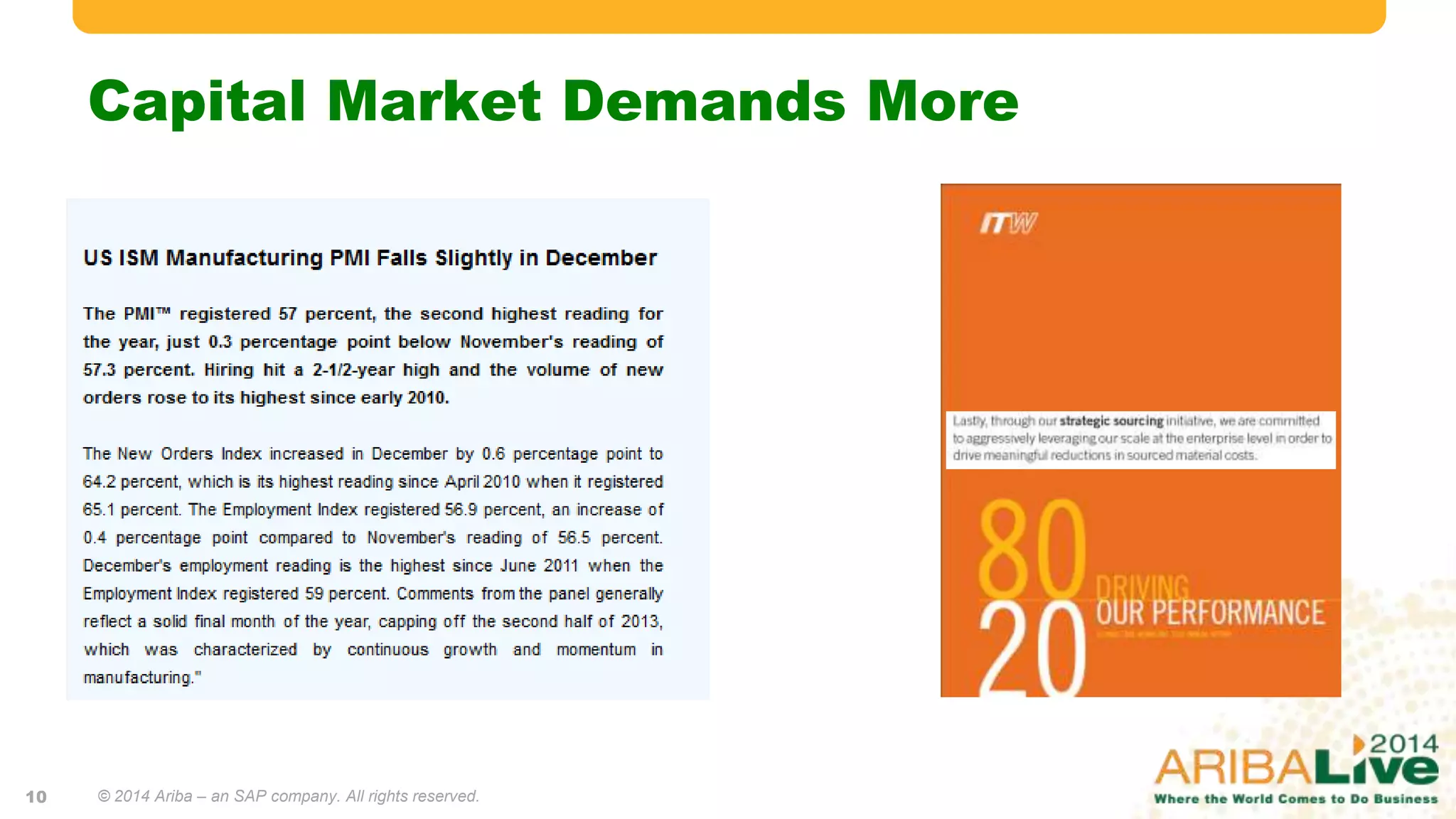

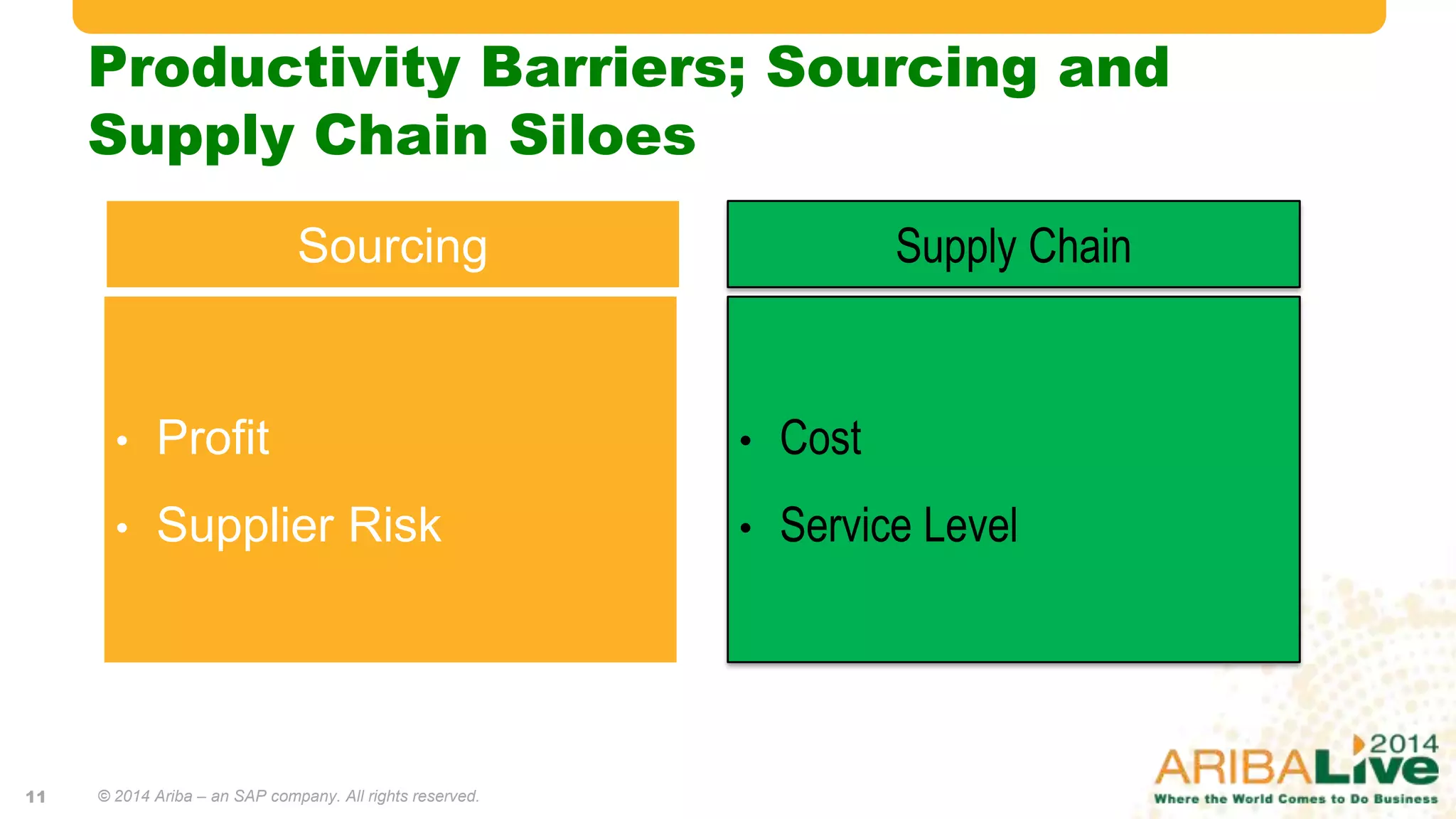

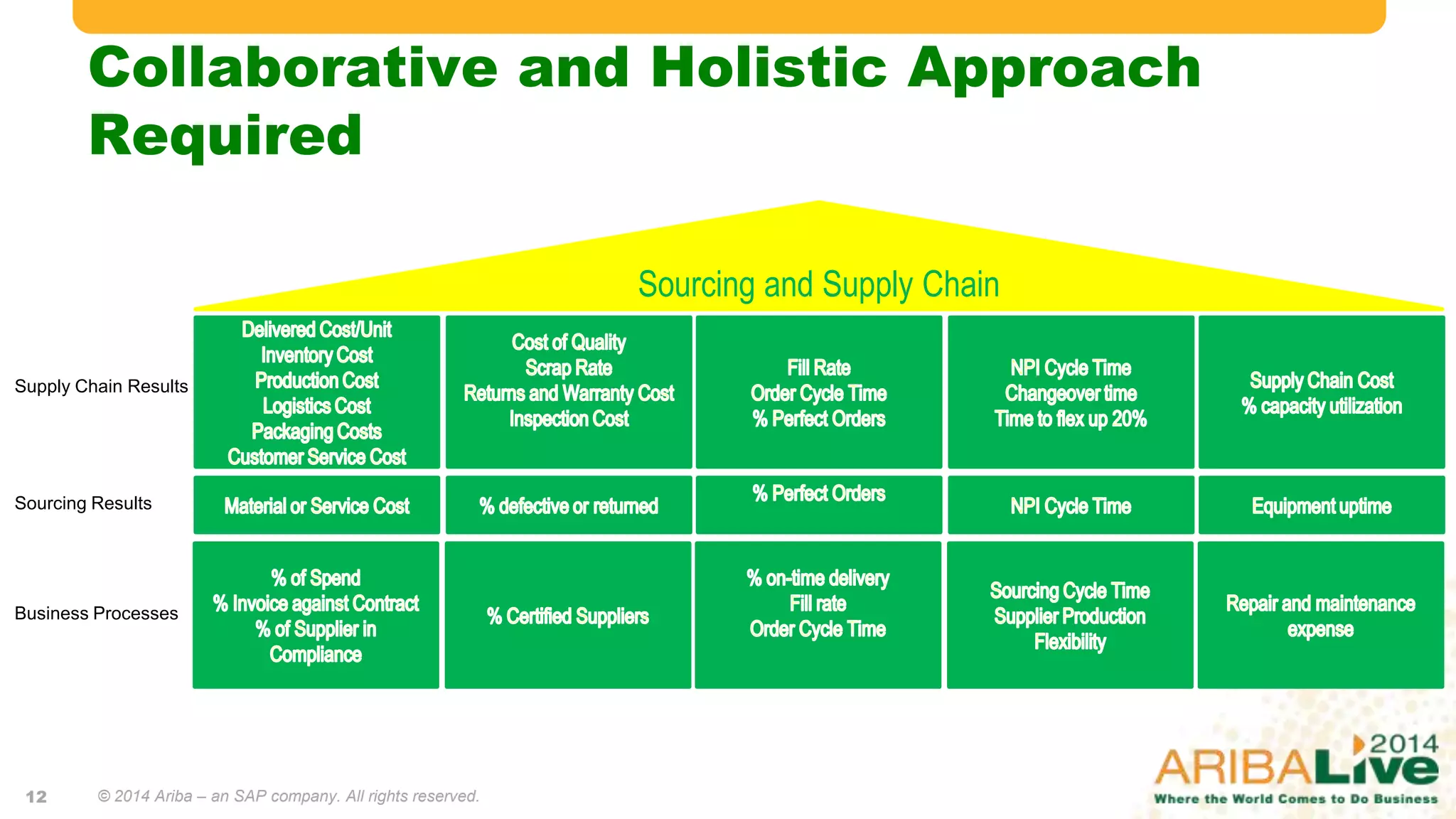

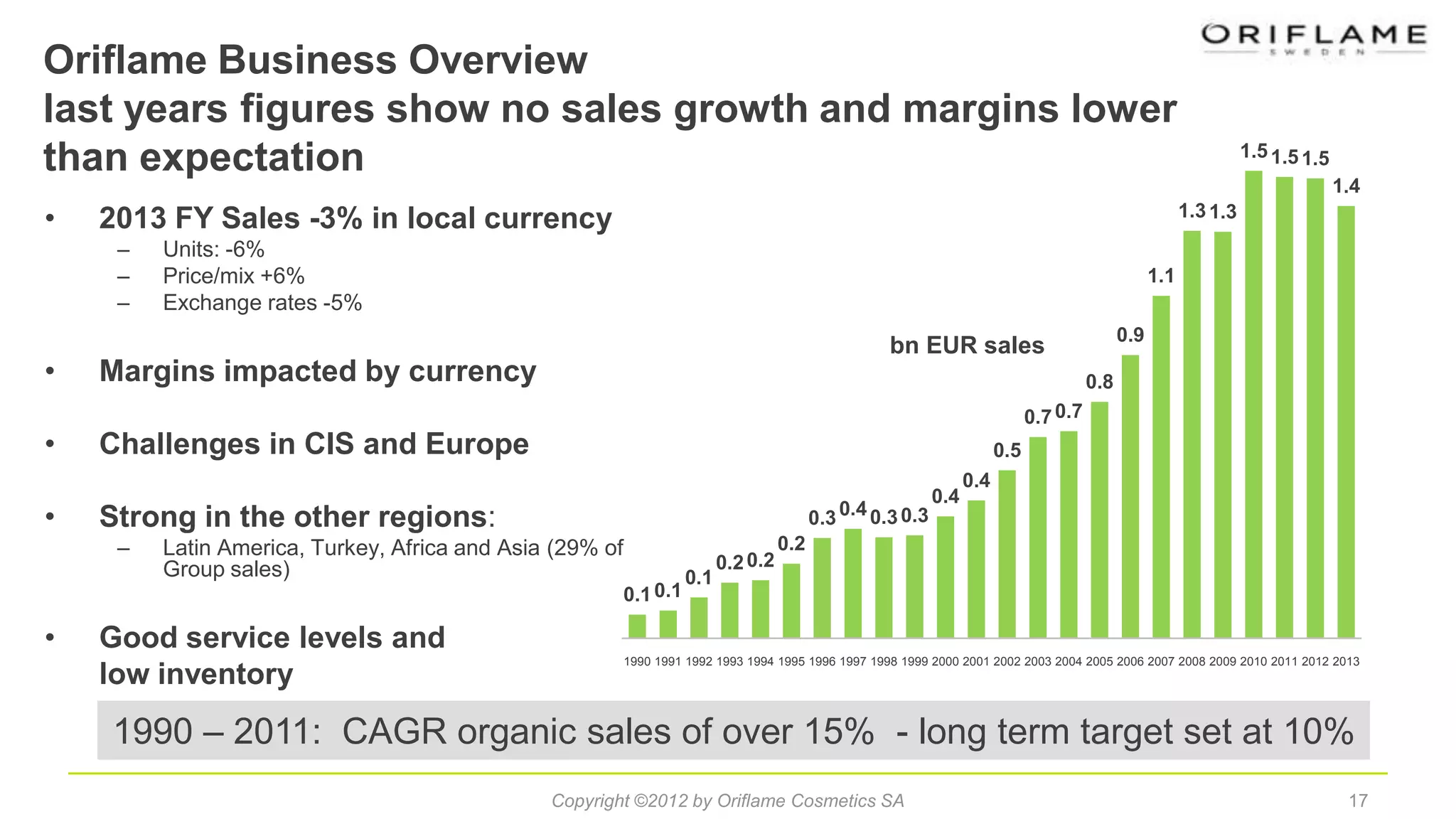

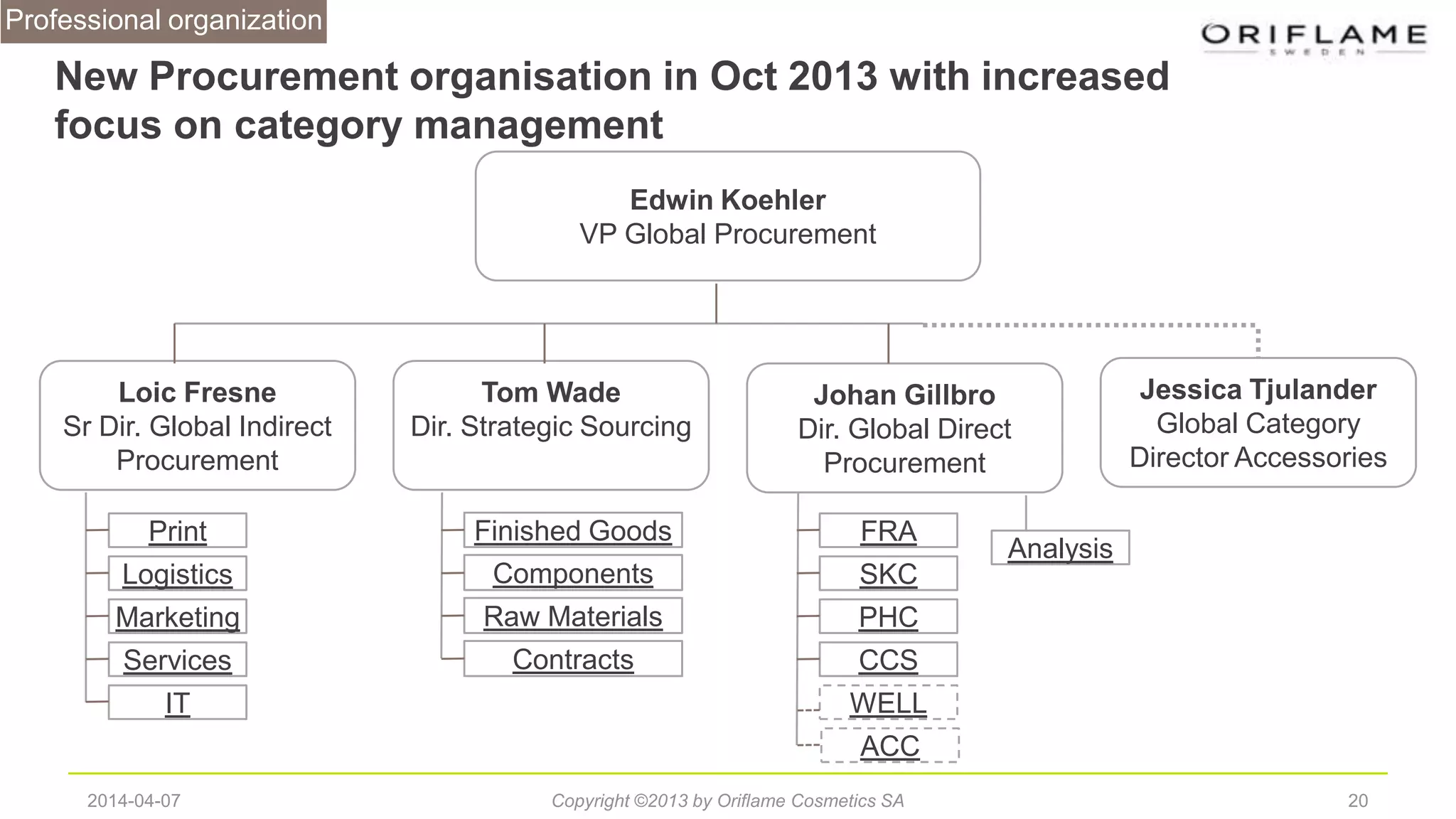

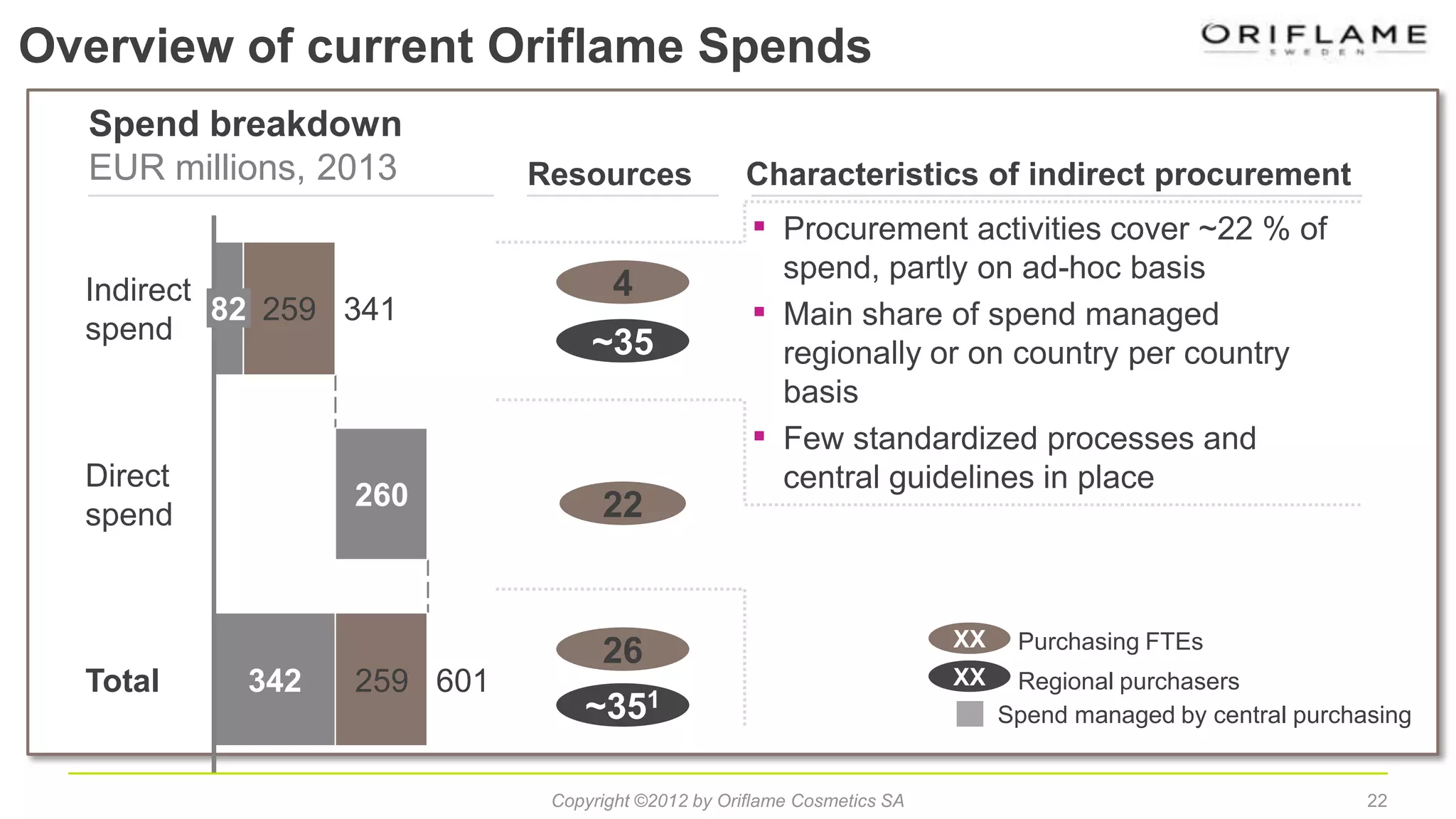

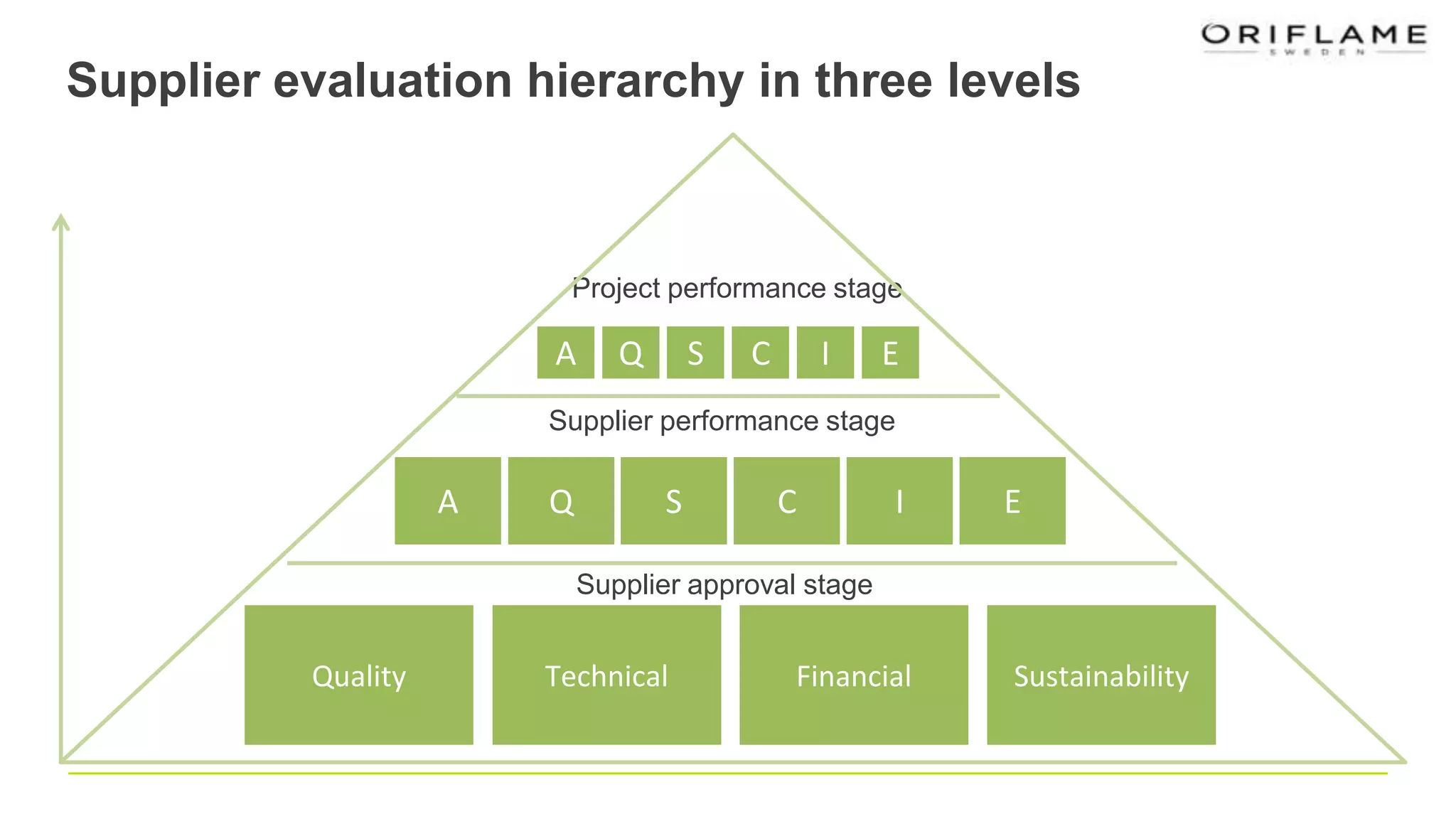

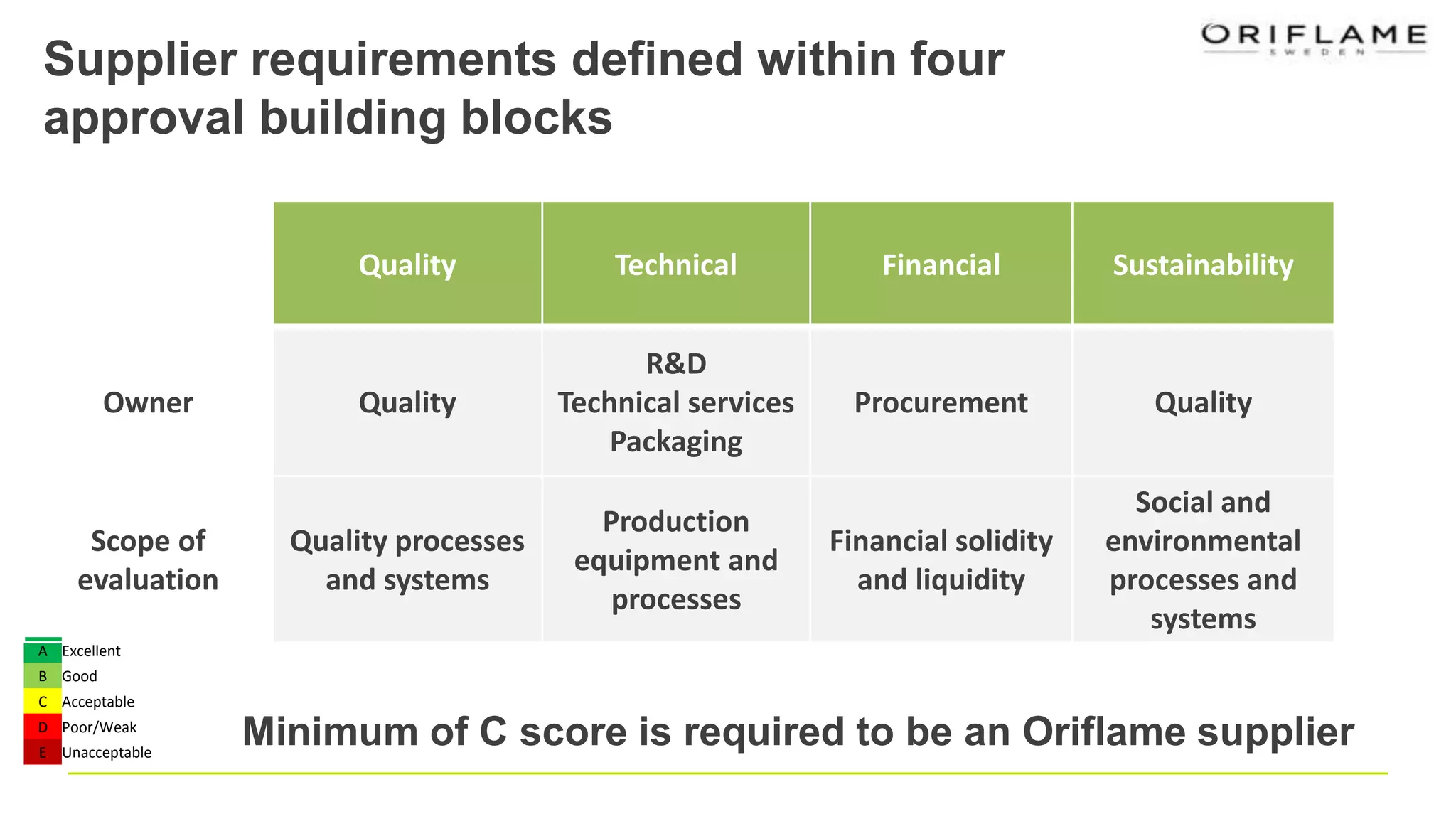

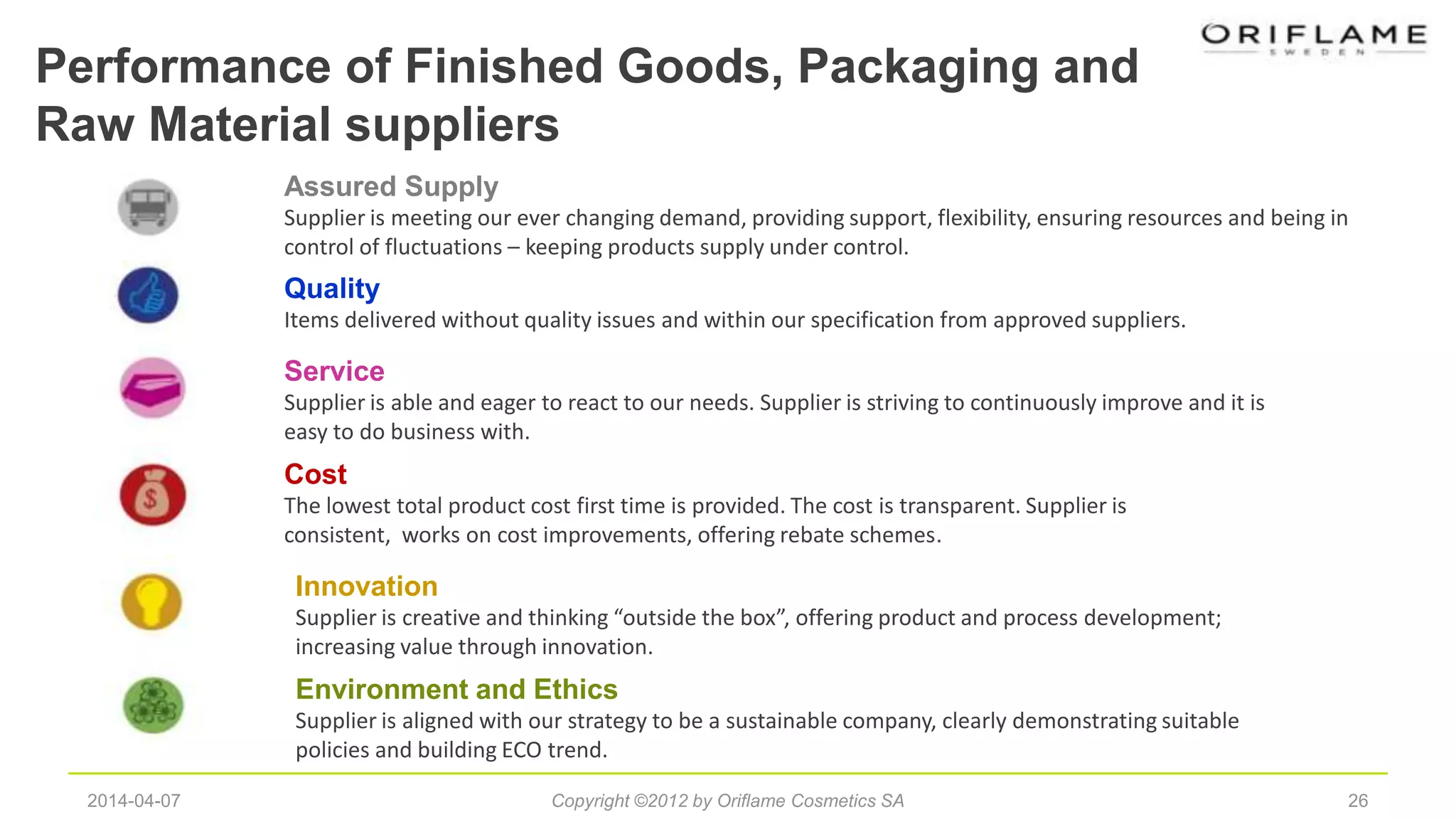

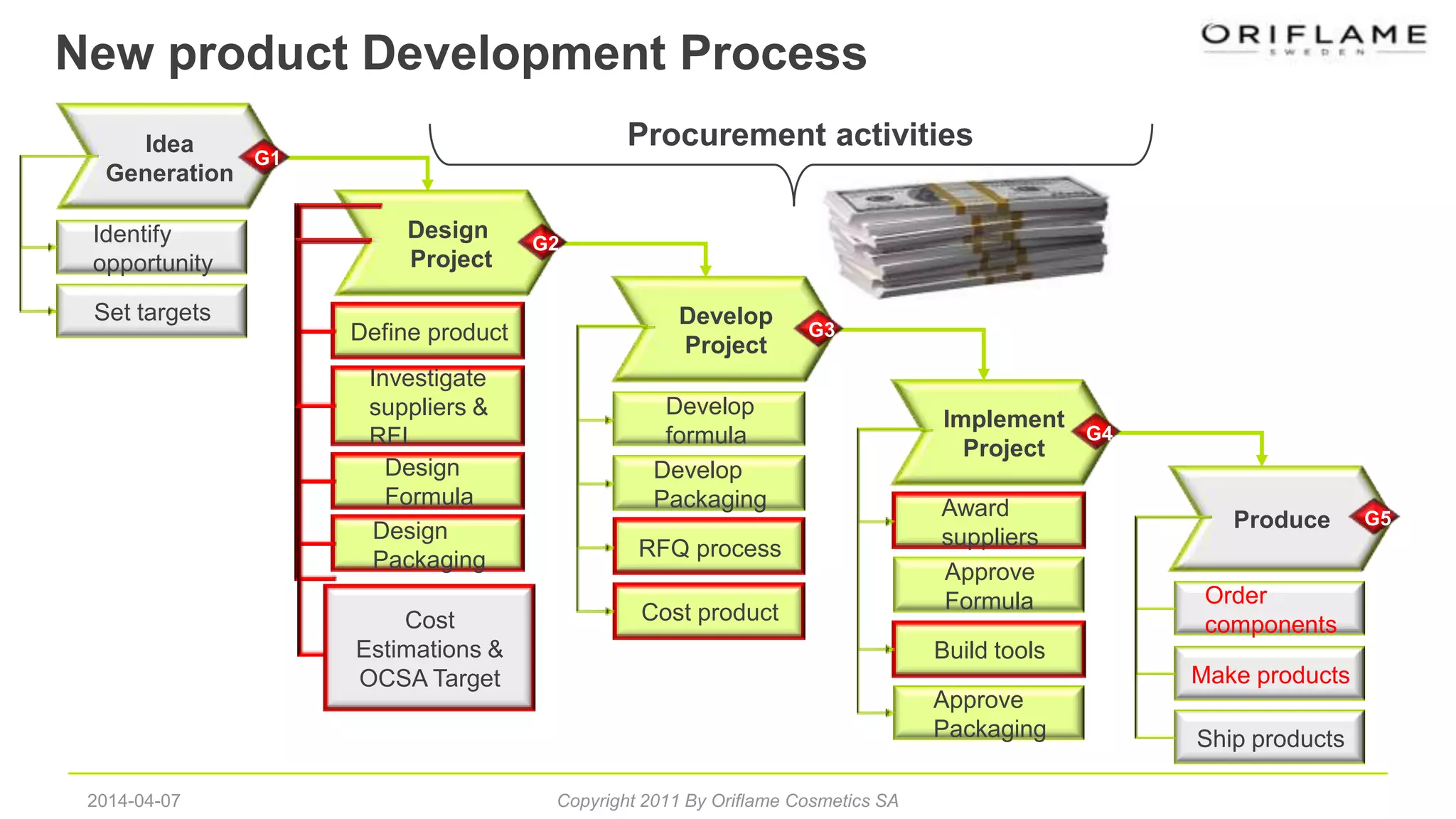

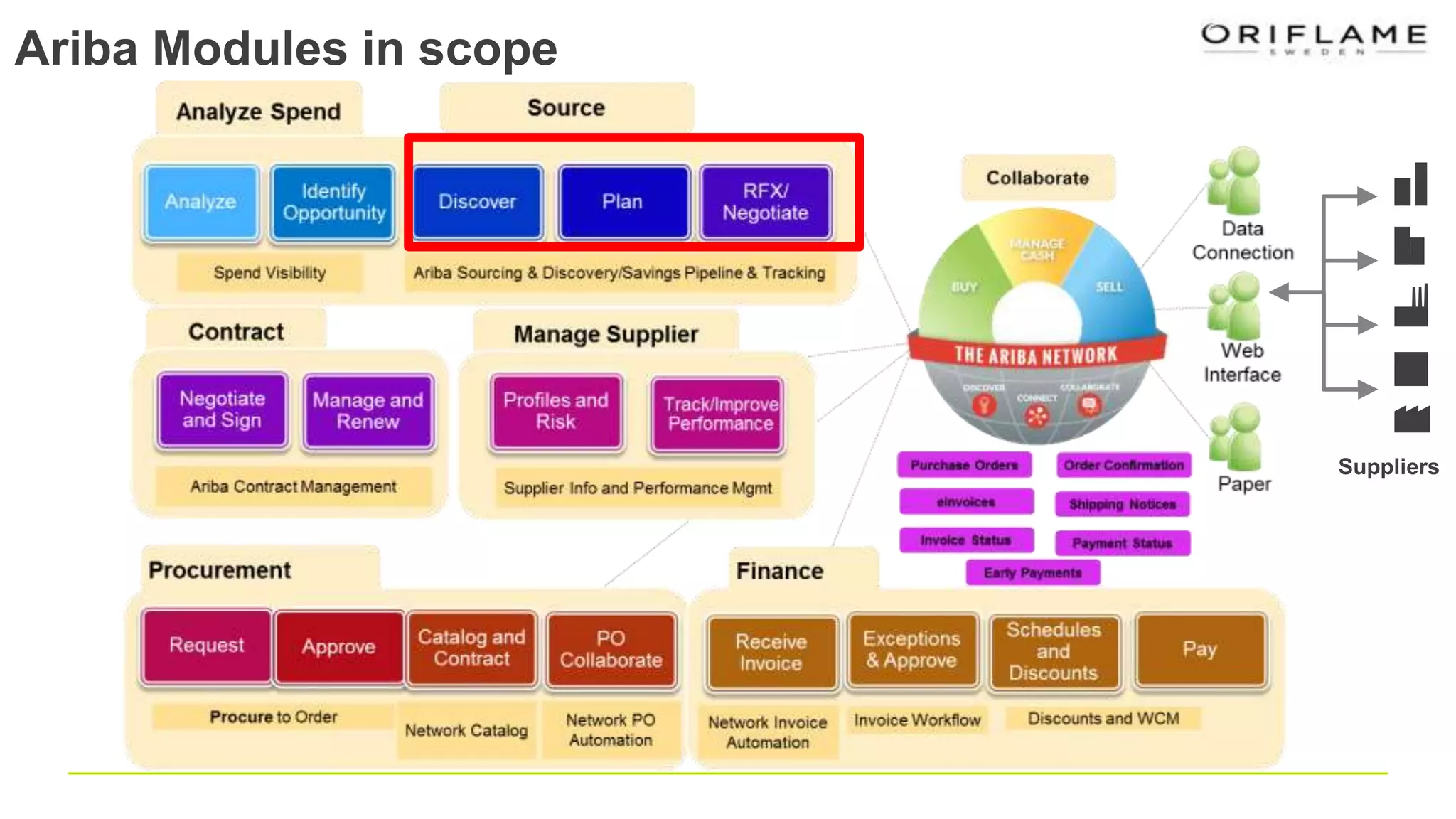

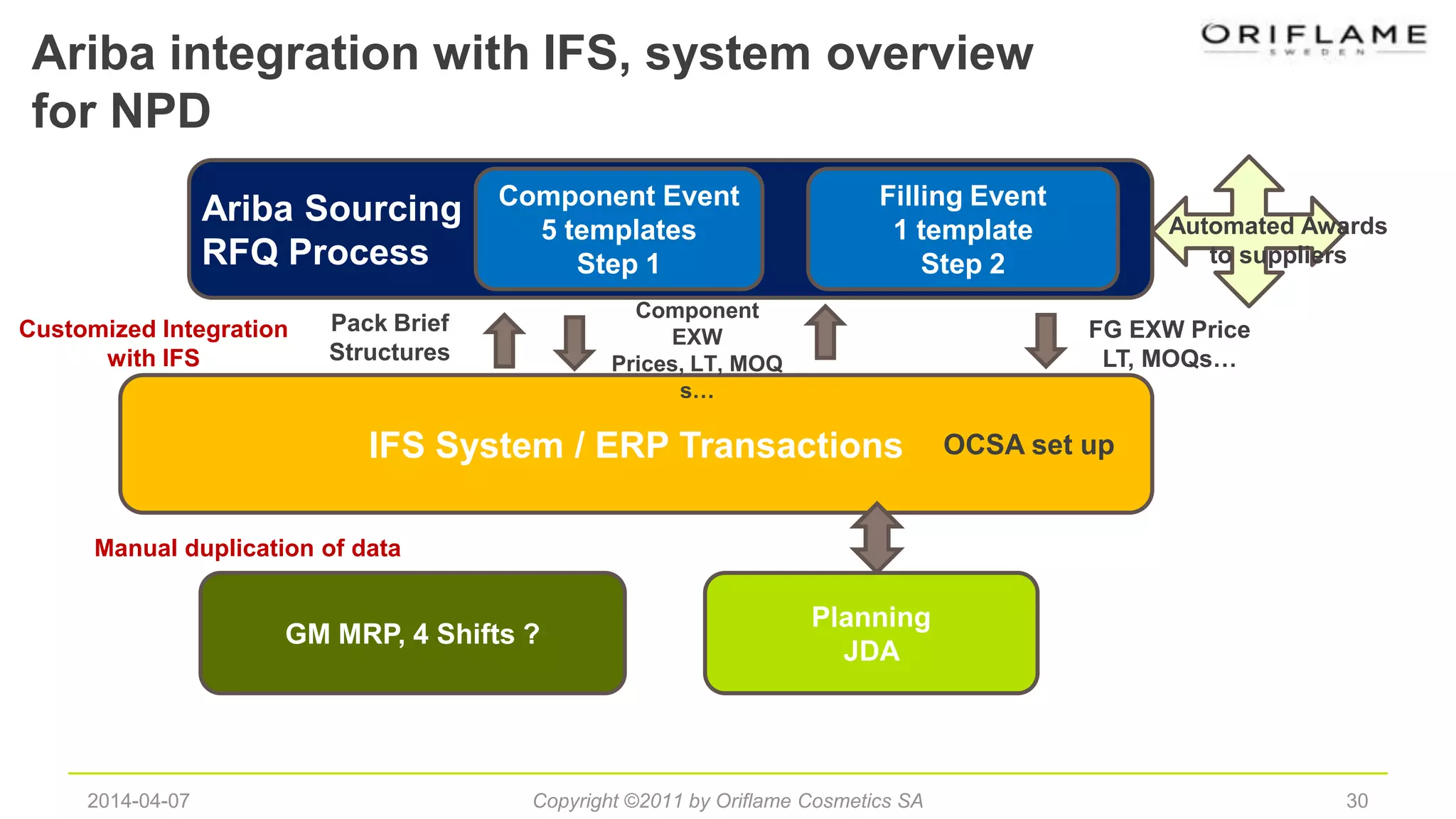

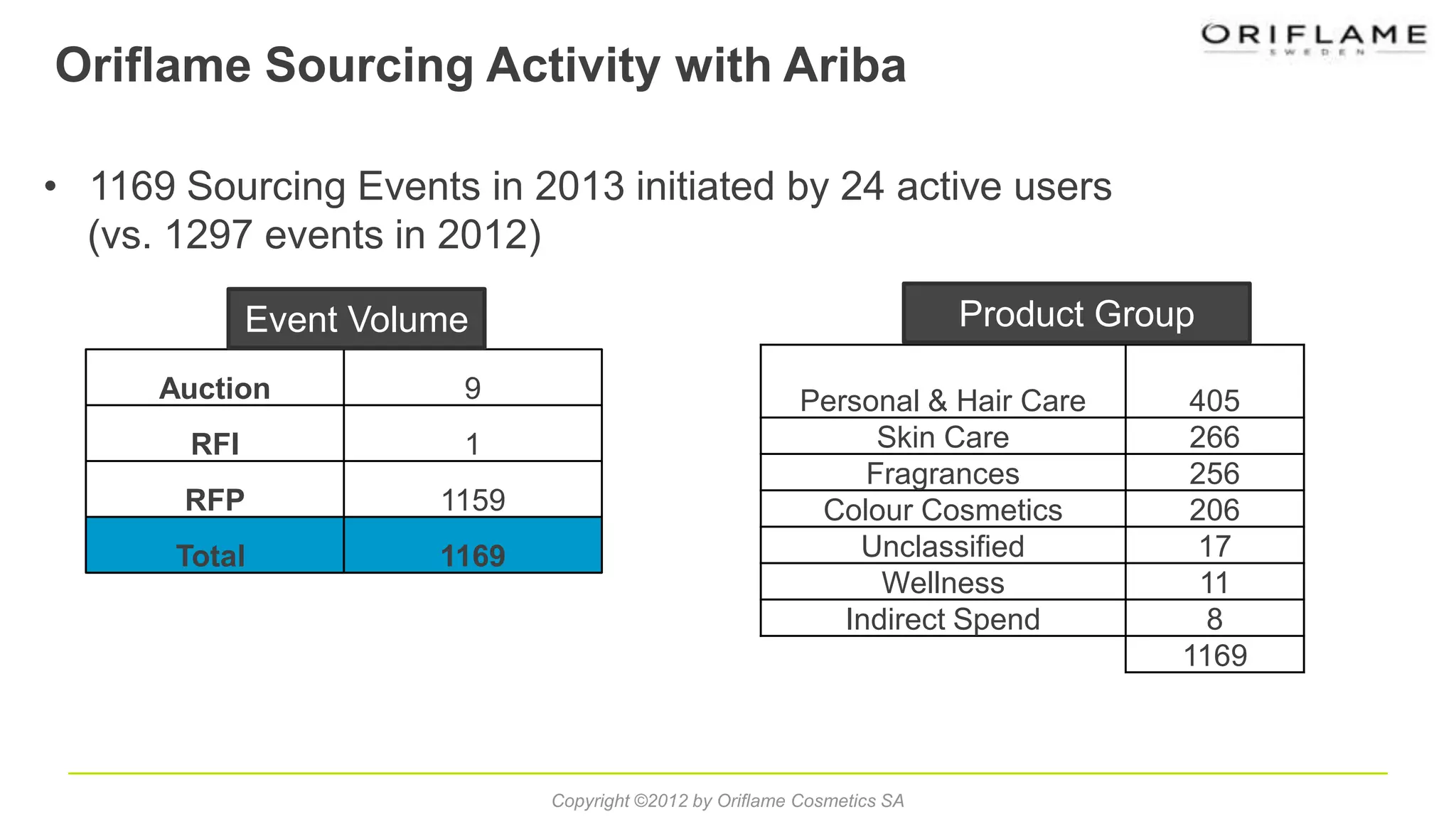

The document discusses strategies for direct materials sourcing and procurement, emphasizing the importance of risk management and cost reduction amid market complexities. It highlights key challenges such as supplier capabilities and price volatility, alongside the collaboration between procurement and finance to enhance efficiency. The use of technology and strategic sourcing tools is recommended for managing different categories of materials to drive savings and improve compliance.