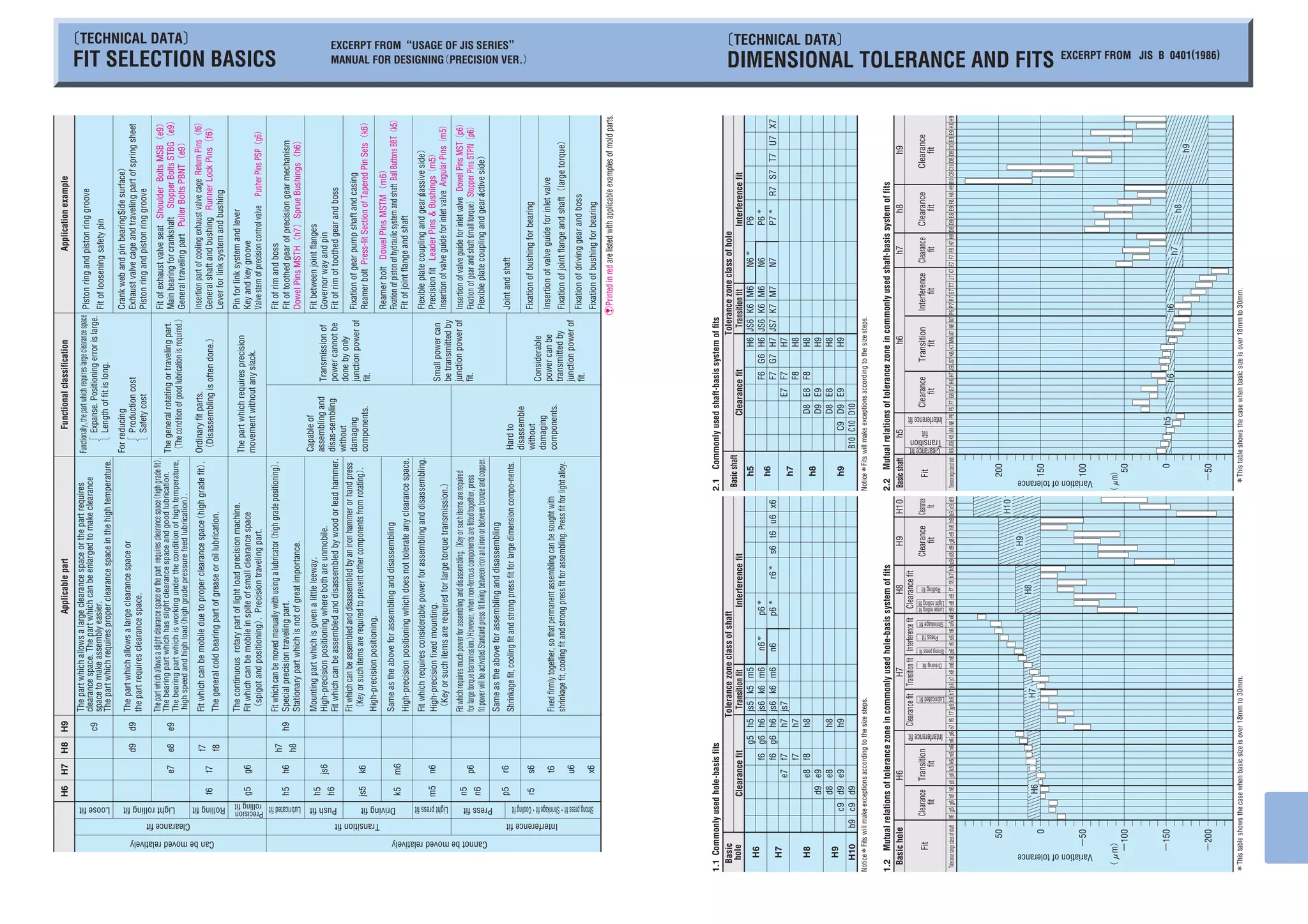

The document discusses different types of fits between machine parts:

1. Loose fit is for parts that require a large clearance space or tolerance for assembly, such as piston rings.

2. Light rolling fit is for bearing parts that have a slight clearance space and good lubrication, such as main bearings.

3. Clearance fit is for parts working under high temperature, speed, and load conditions that require lubrication, such as crank webs.