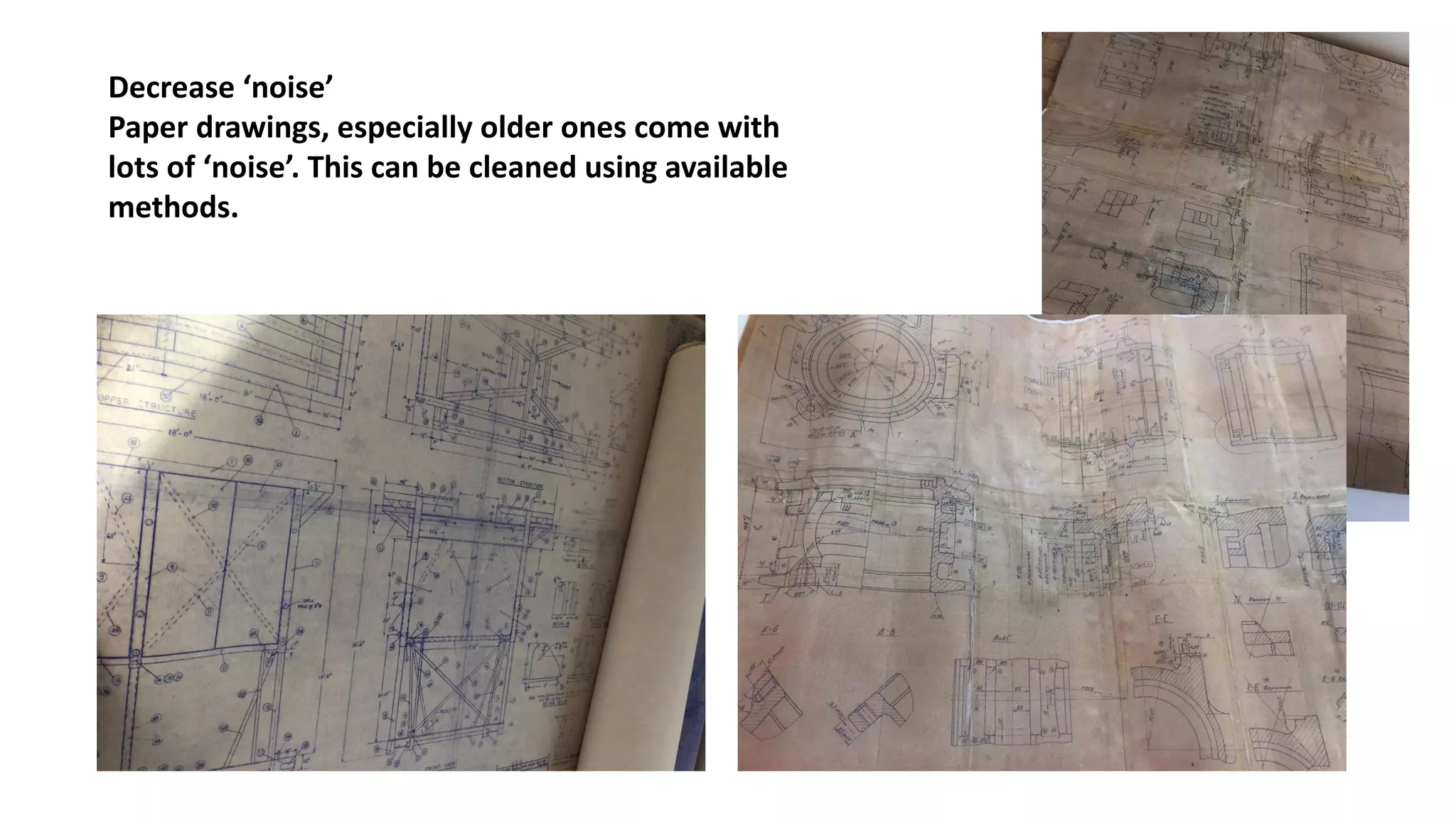

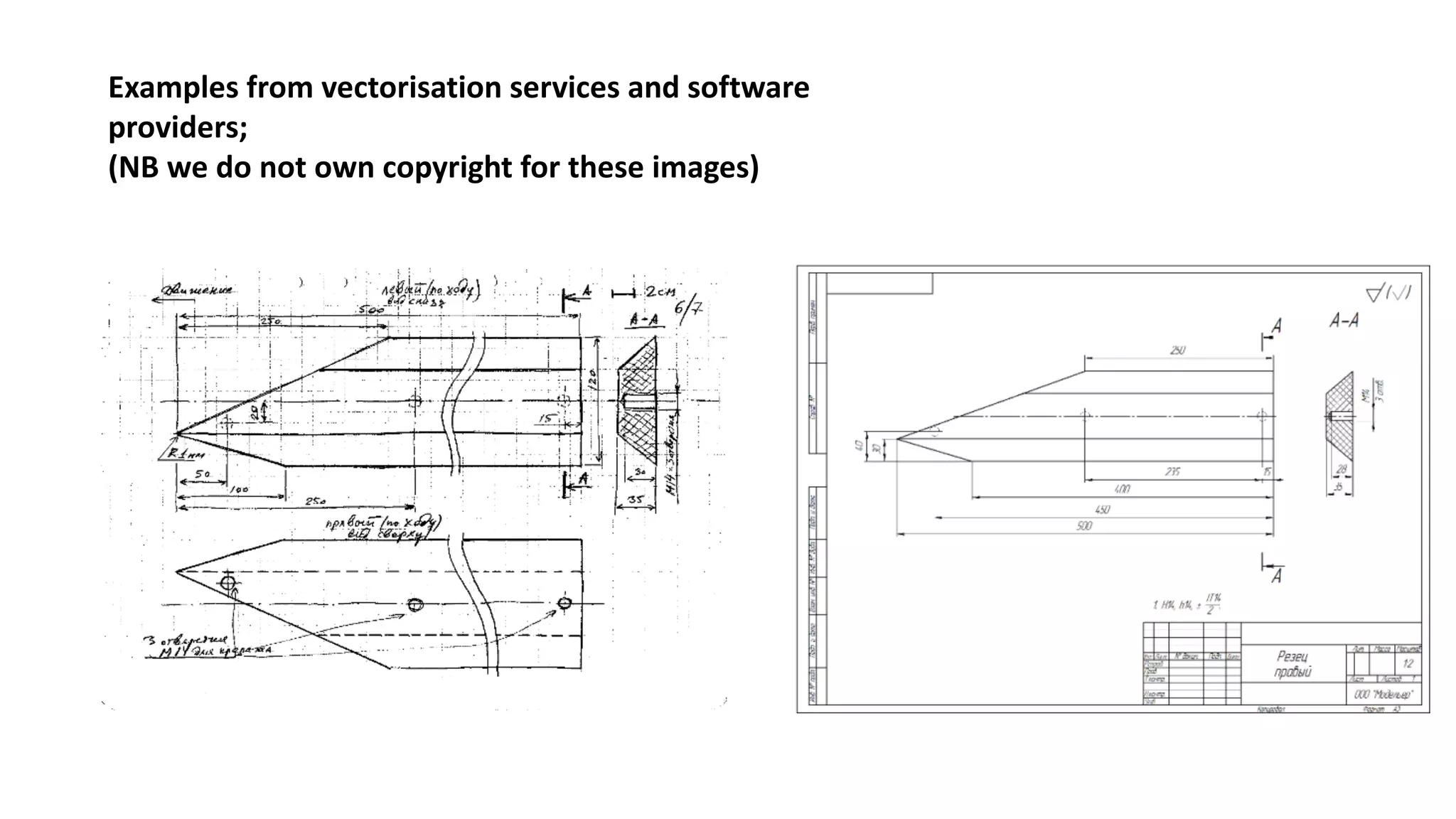

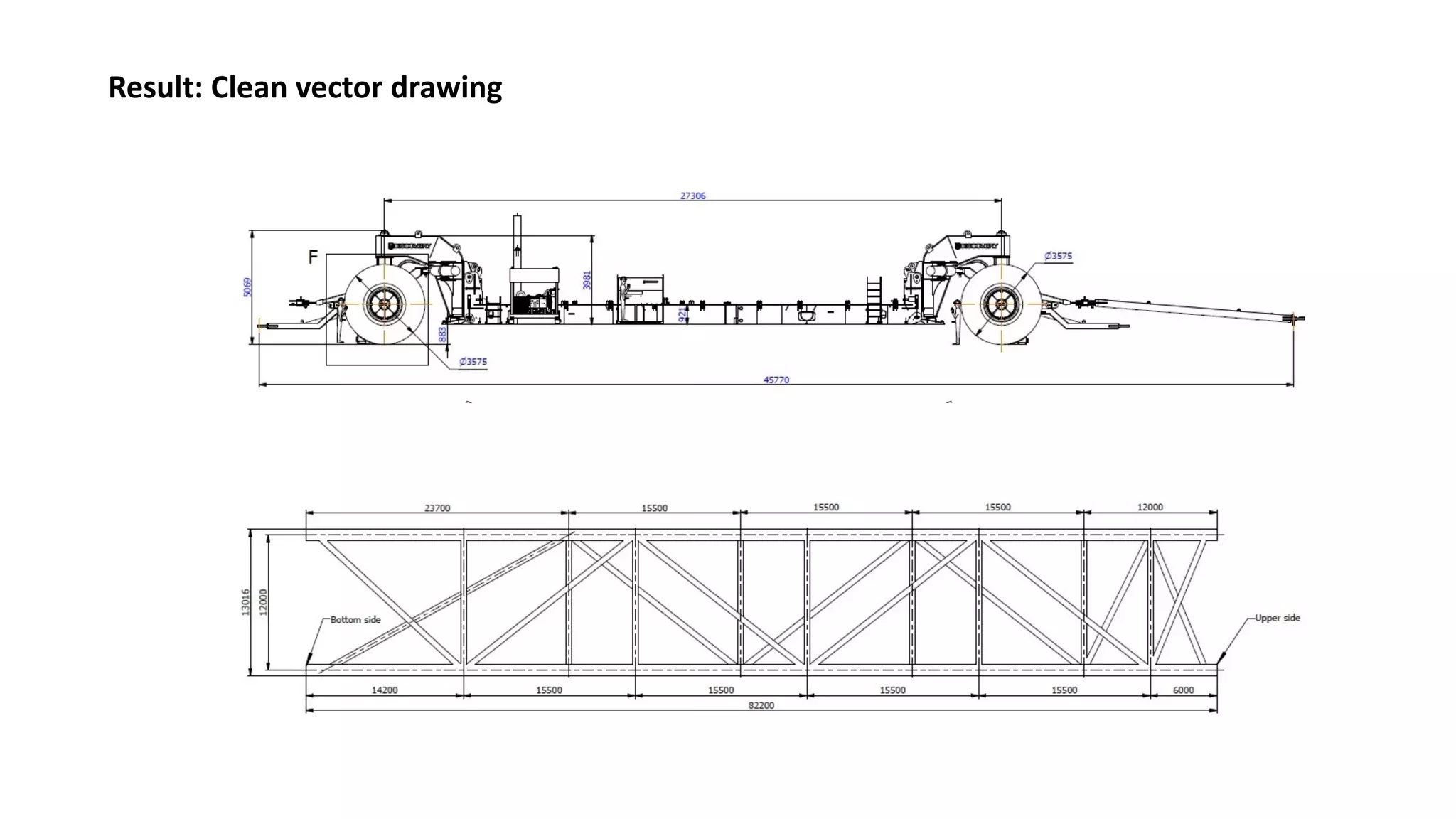

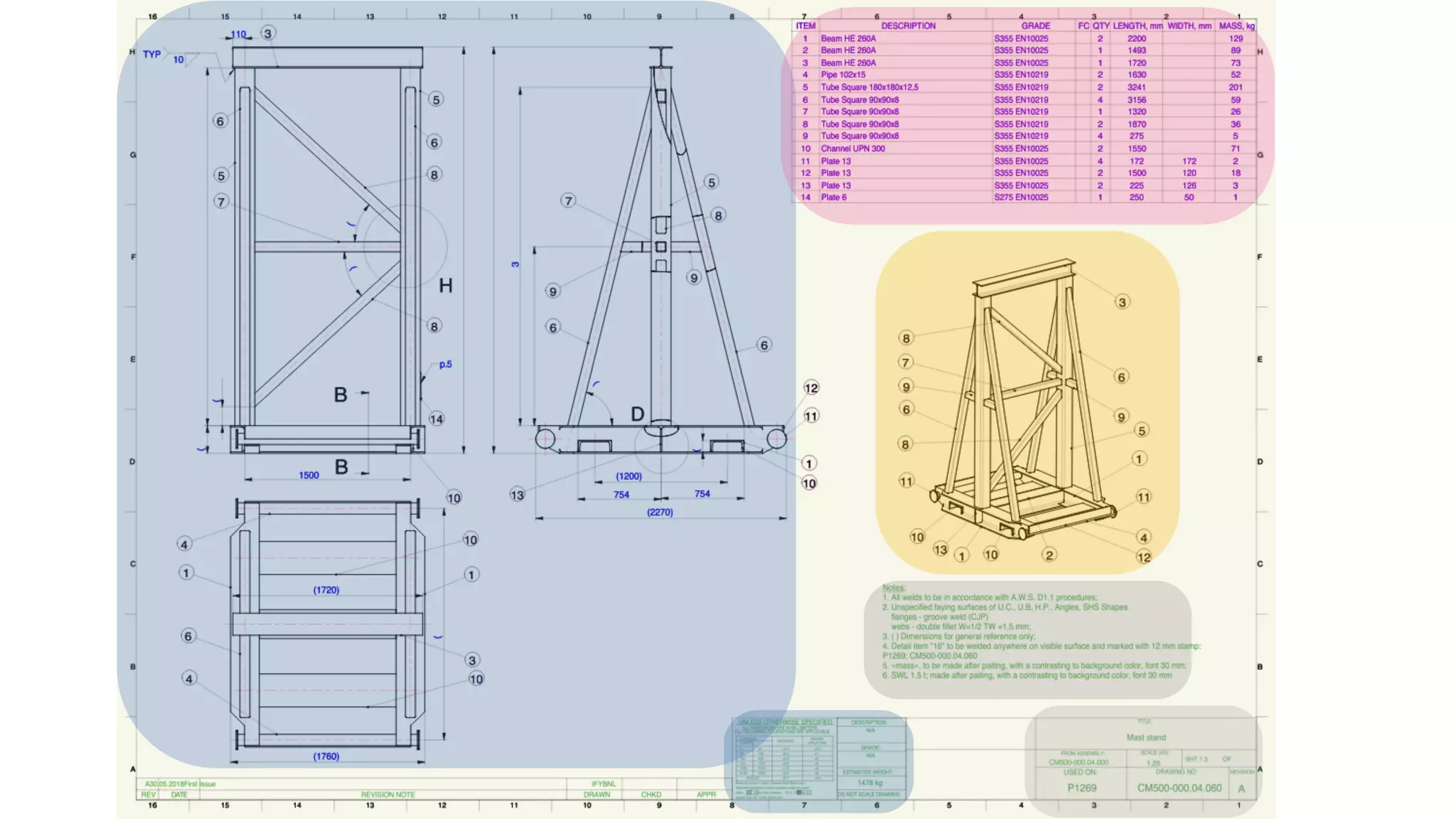

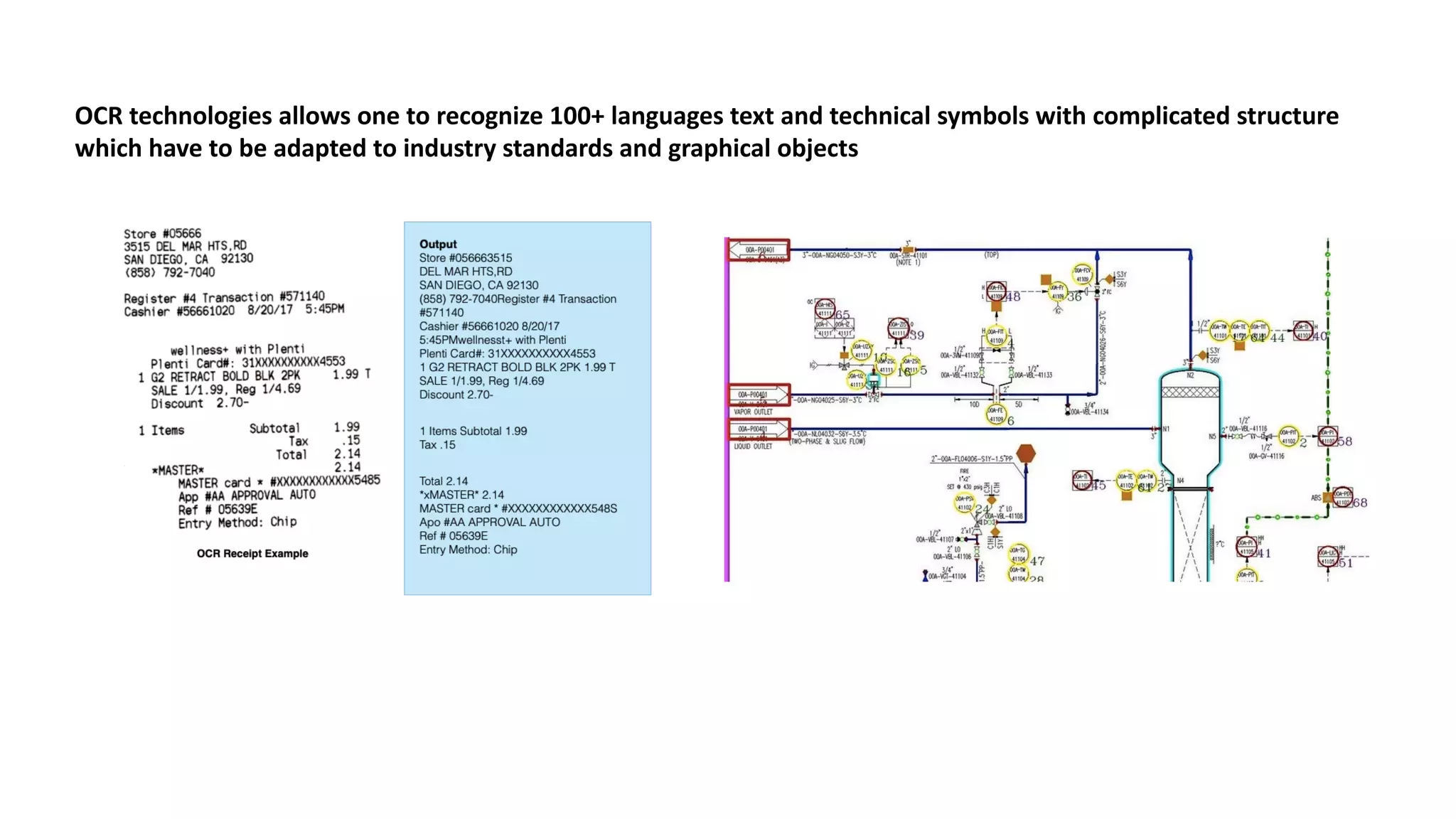

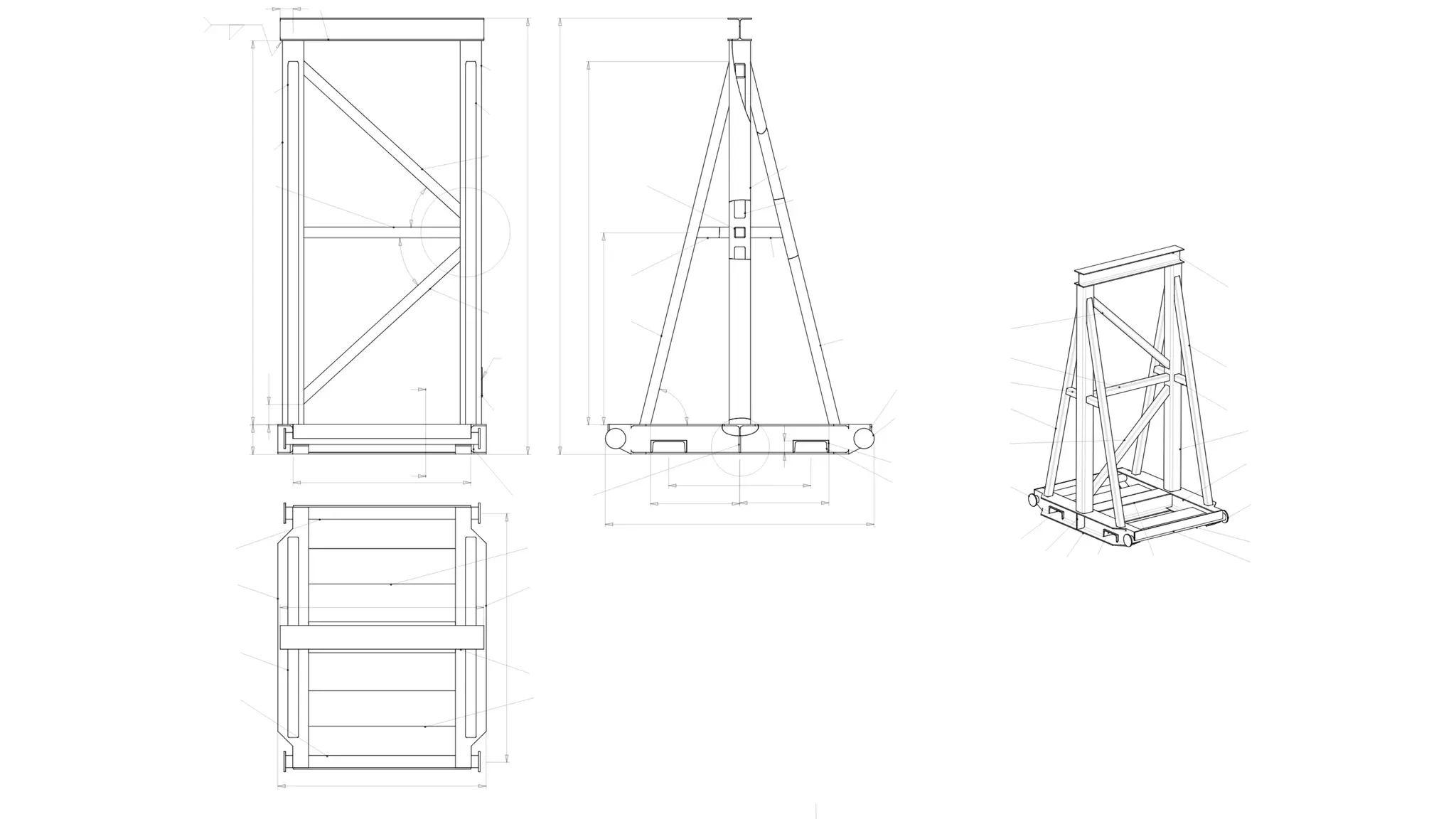

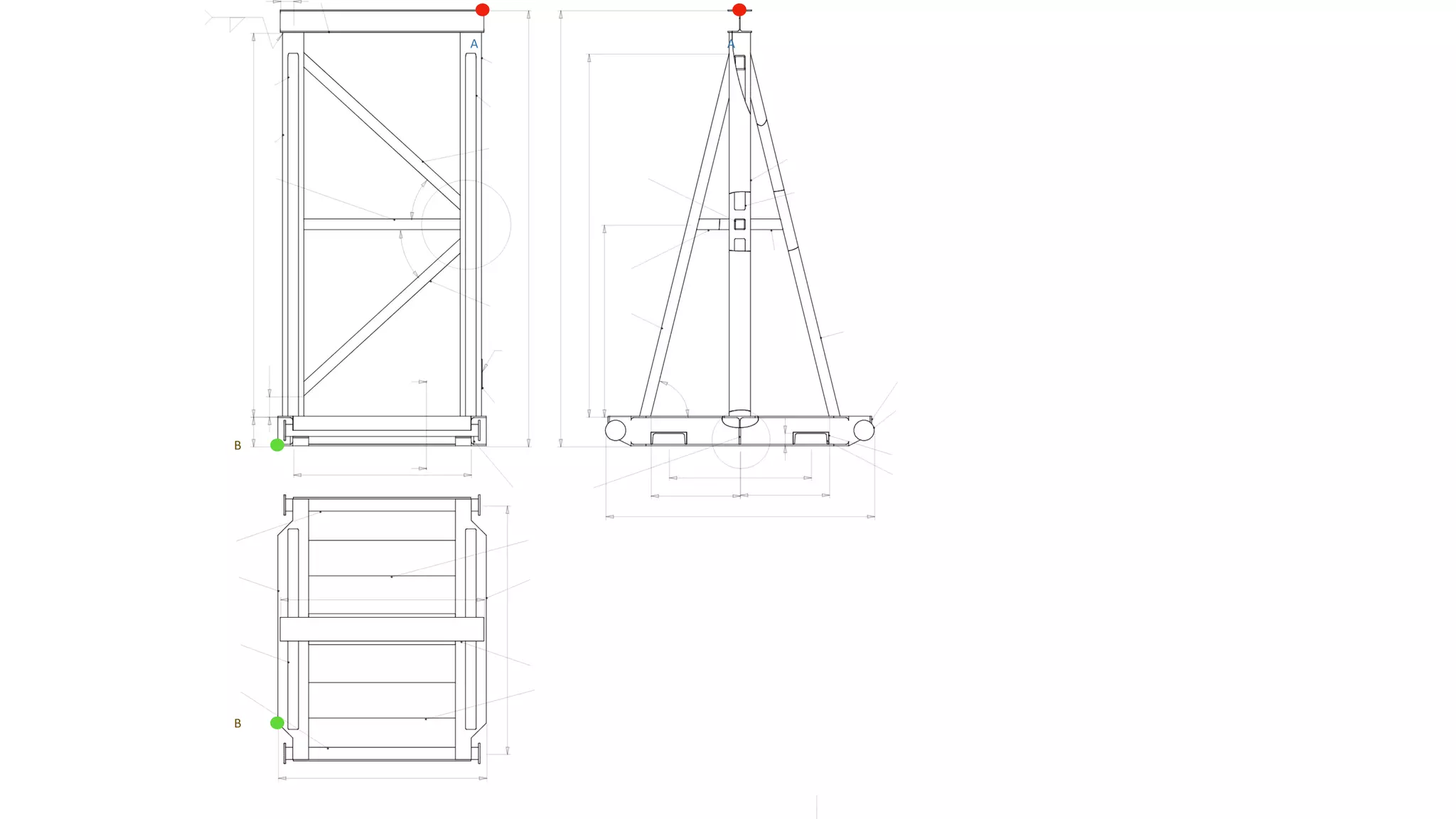

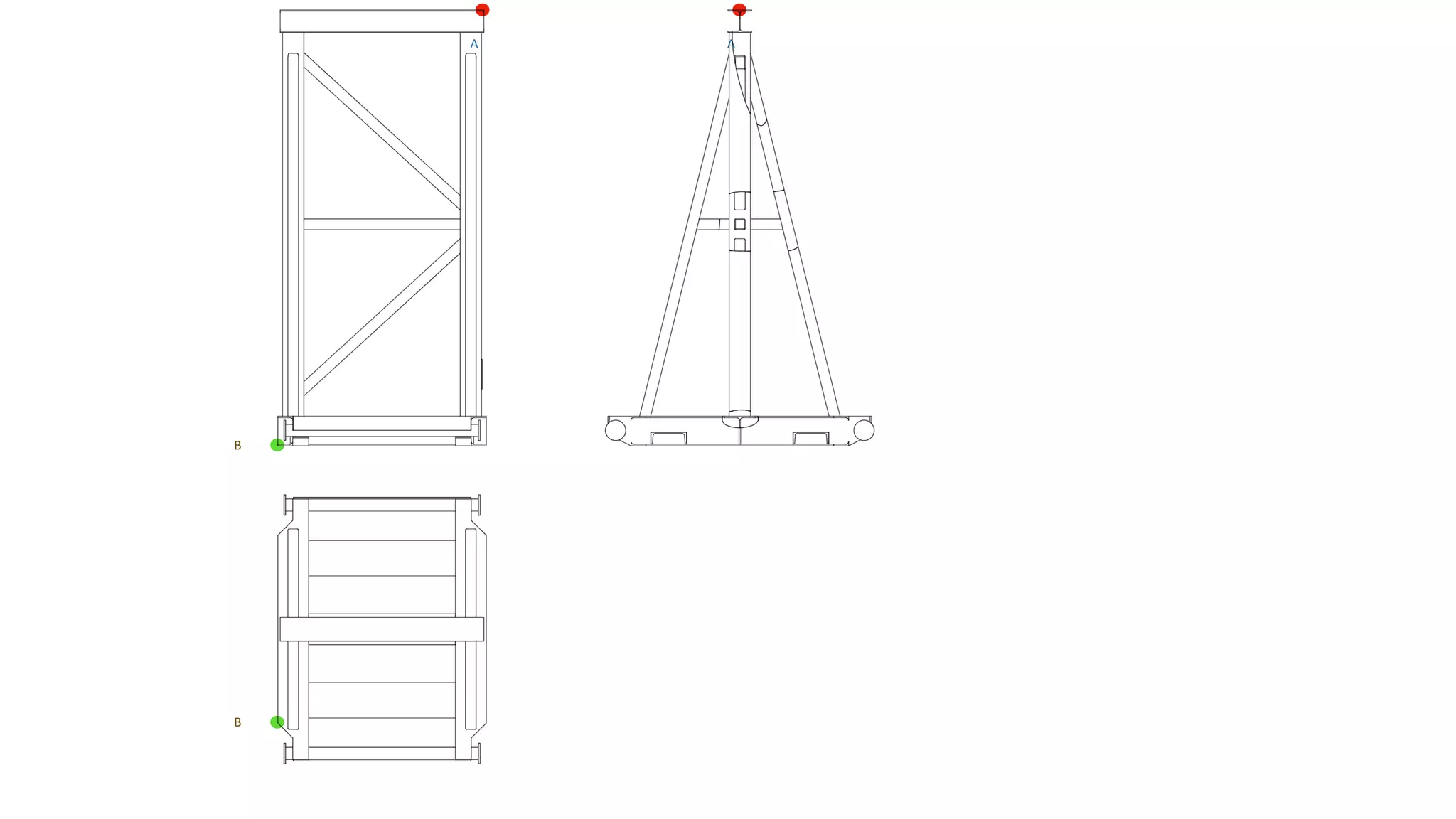

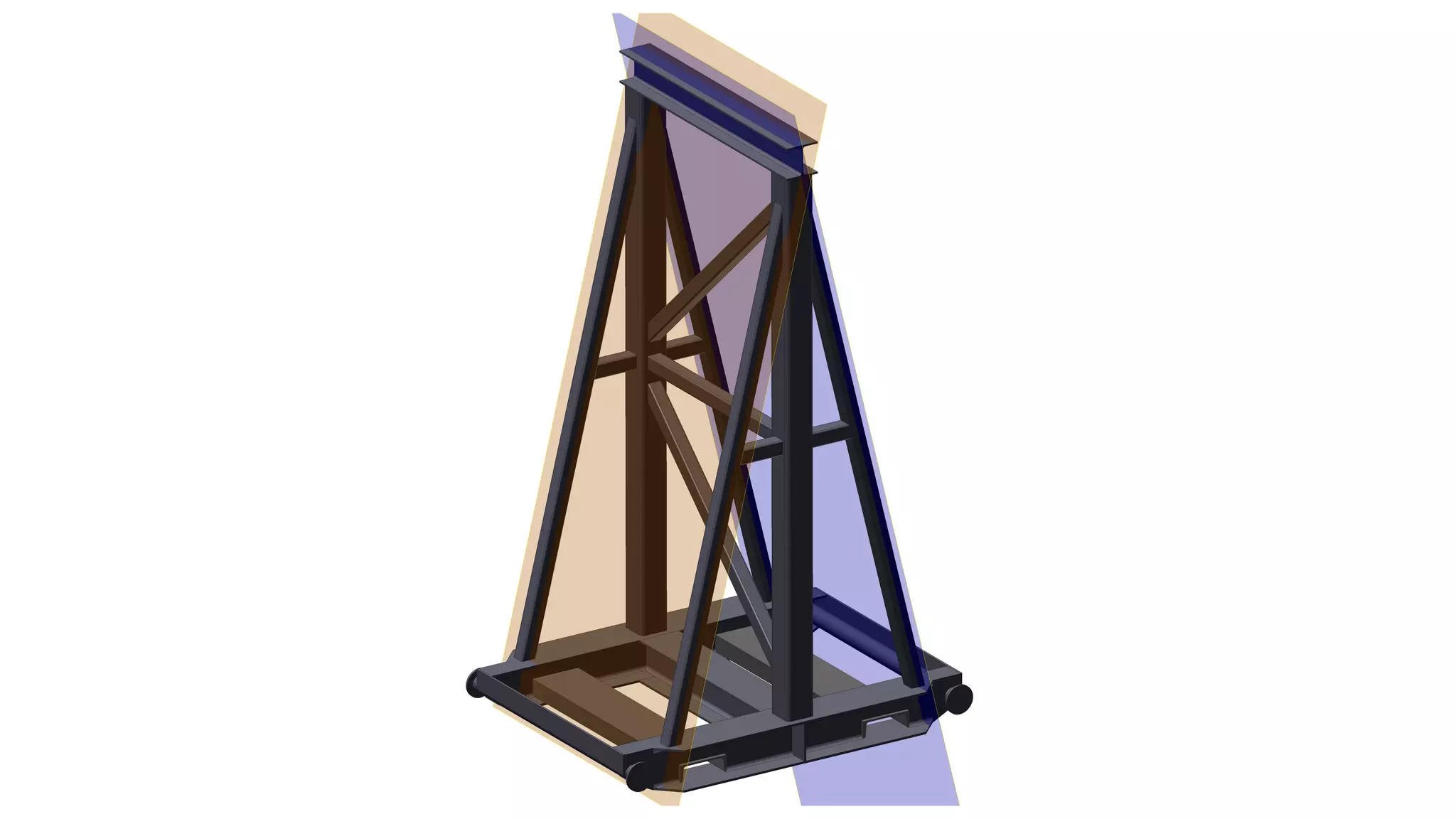

The document details the process of converting 2D drawings into 3D models using DII's AI platform, emphasizing the importance of obtaining accurate information about object parts, materials, and components. It outlines key methods such as de-noising and vectorizing images, recognizing functional areas and symbols, and utilizing computer vision techniques to ensure precise transformations. The steps involve utilizing existing algorithms and automating the recognition process to create digital models in alignment with industry standards.