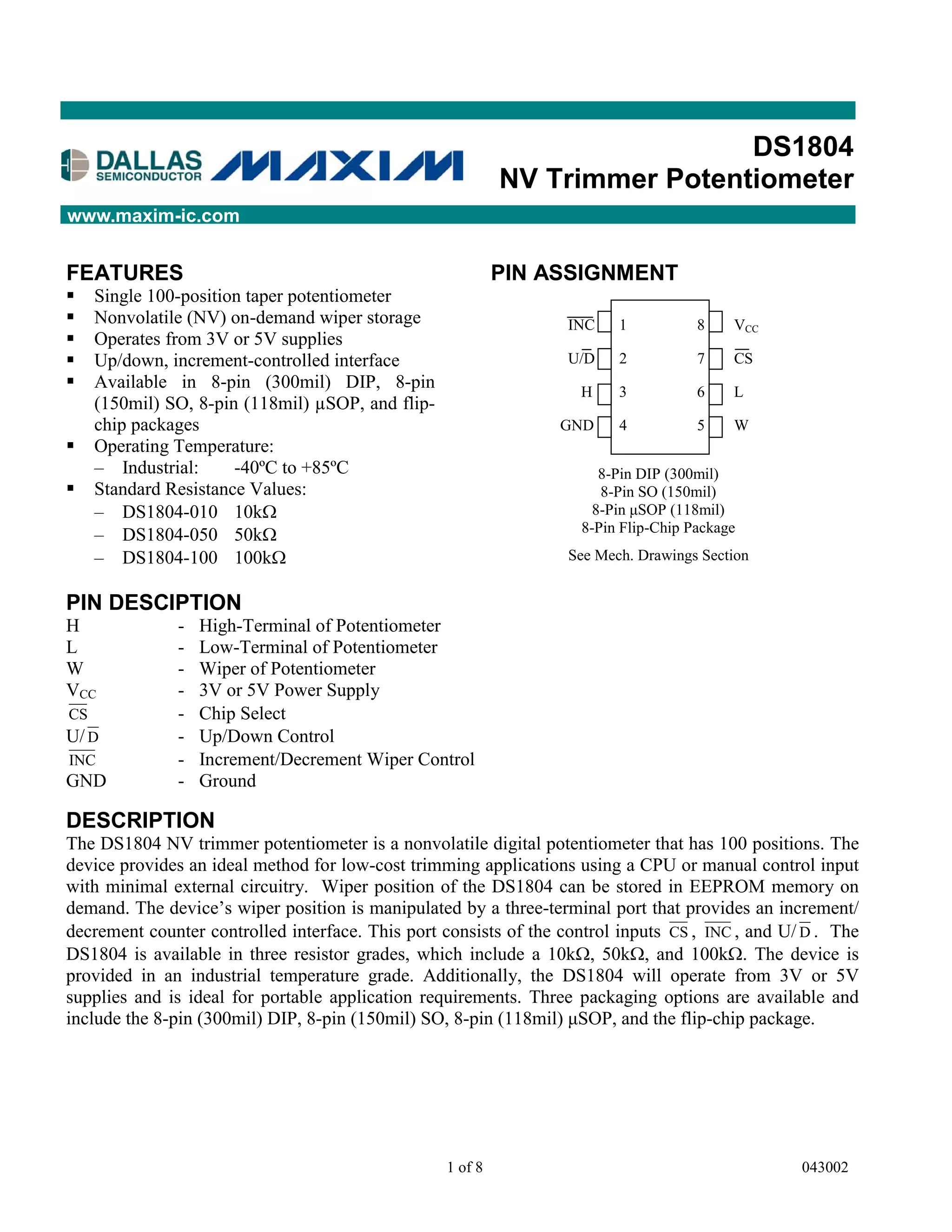

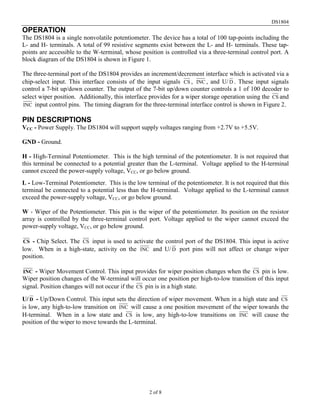

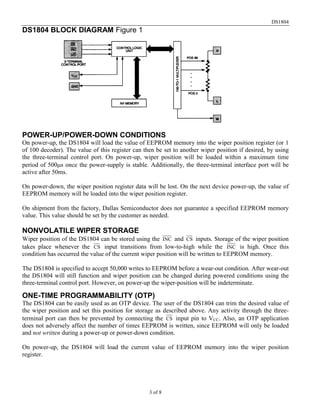

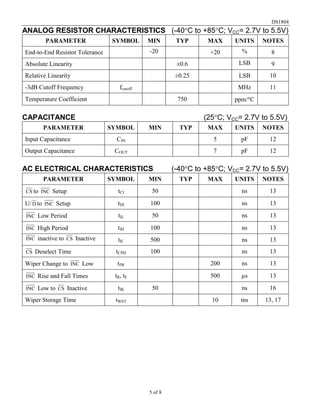

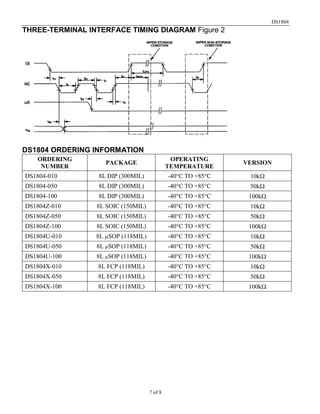

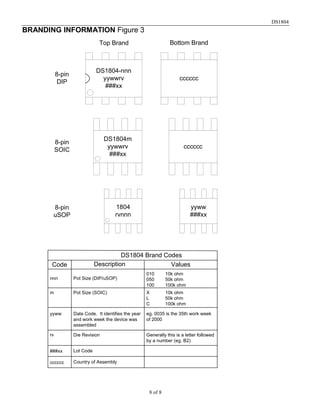

The DS1804 is a single 100-position nonvolatile trimmer potentiometer that can store the wiper position in EEPROM memory. It has a three-terminal interface to control the wiper position using increment/decrement signals and can operate from 3V to 5V supplies. It comes in 8-pin DIP, SOIC, and μSOP packages with resistance values of 10kW, 50kW, and 100kW.