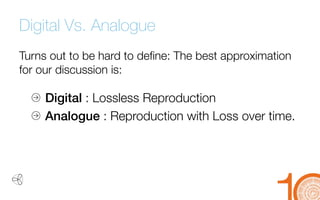

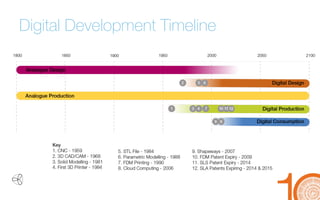

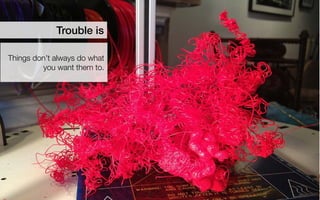

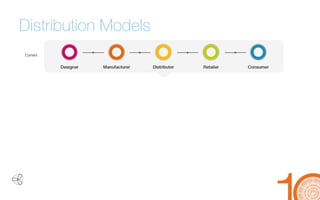

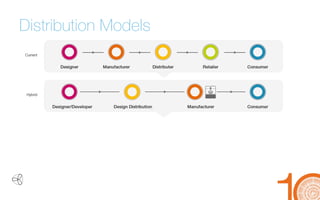

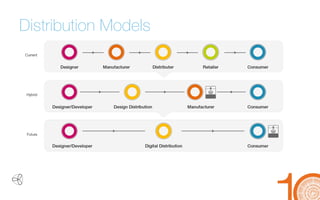

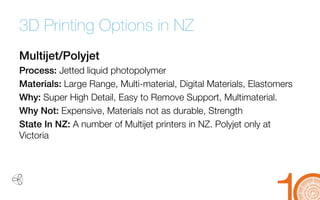

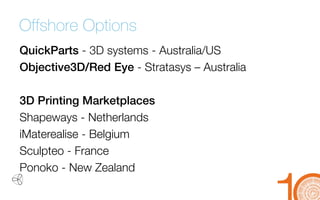

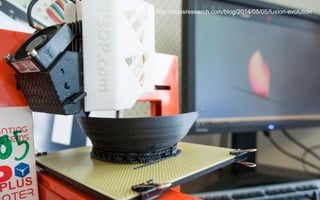

The document explores the challenges and opportunities of digital versus analogue methods in product development, highlighting the advantages of digital manufacturing such as design flexibility and rapid iterations, while also acknowledging the limitations imposed by current analogue methods. It discusses various 3D printing technologies available in New Zealand, their materials and processes, and emphasizes the need for a hybrid approach due to material limitations. Overall, it stresses the importance of keeping abreast of advancements in digital distribution and manufacturing, particularly for companies involved in plastics production.