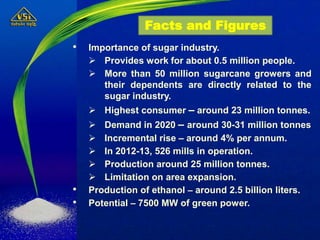

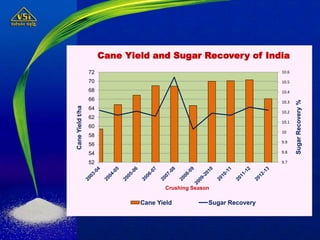

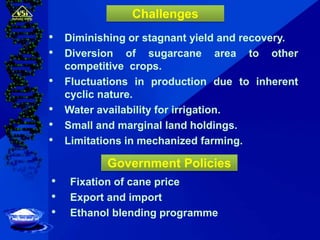

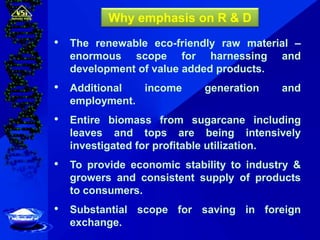

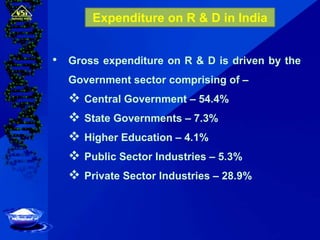

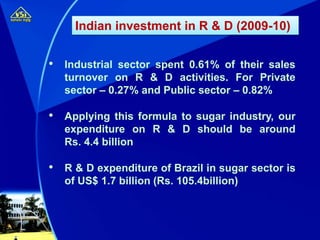

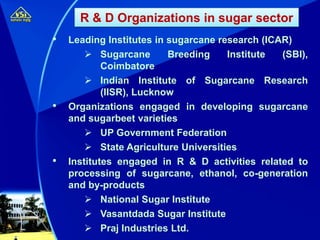

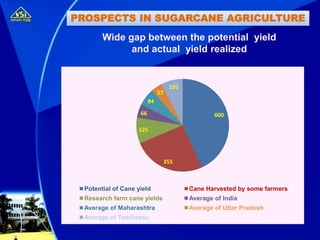

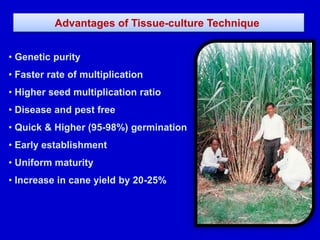

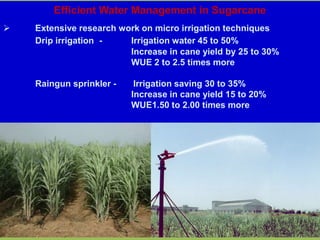

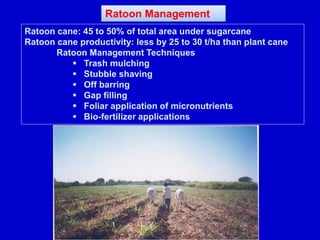

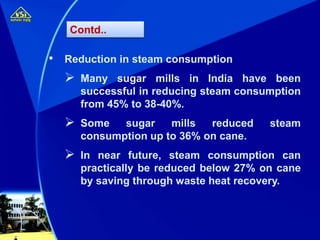

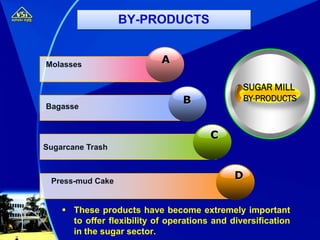

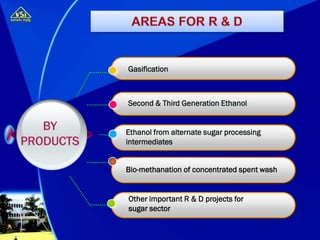

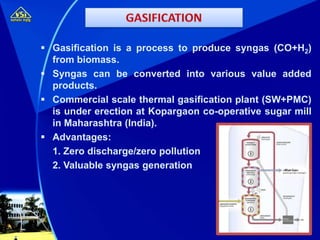

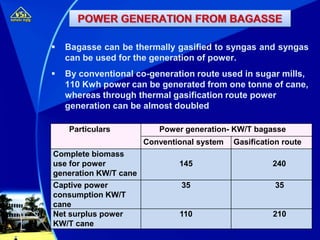

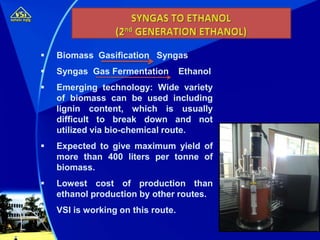

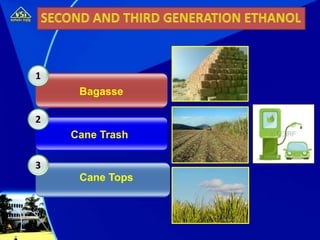

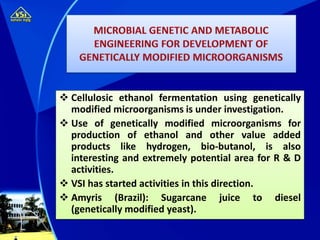

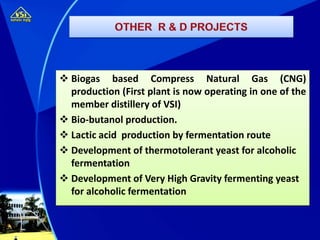

The document discusses the importance of the sugar industry in India and outlines opportunities for research and development. It notes that the sugar industry provides livelihoods for millions of people but faces challenges of fluctuating production and stagnating yields. It highlights priority areas for R&D such as varietal development, irrigation techniques, mechanization, and integrated pest management. Additionally, it outlines opportunities to increase ethanol production through technologies like gasification and genetic engineering. The document emphasizes the need for increased investment in R&D to make the industry globally competitive and ensure its long-term stability and growth.