Embed presentation

Download to read offline

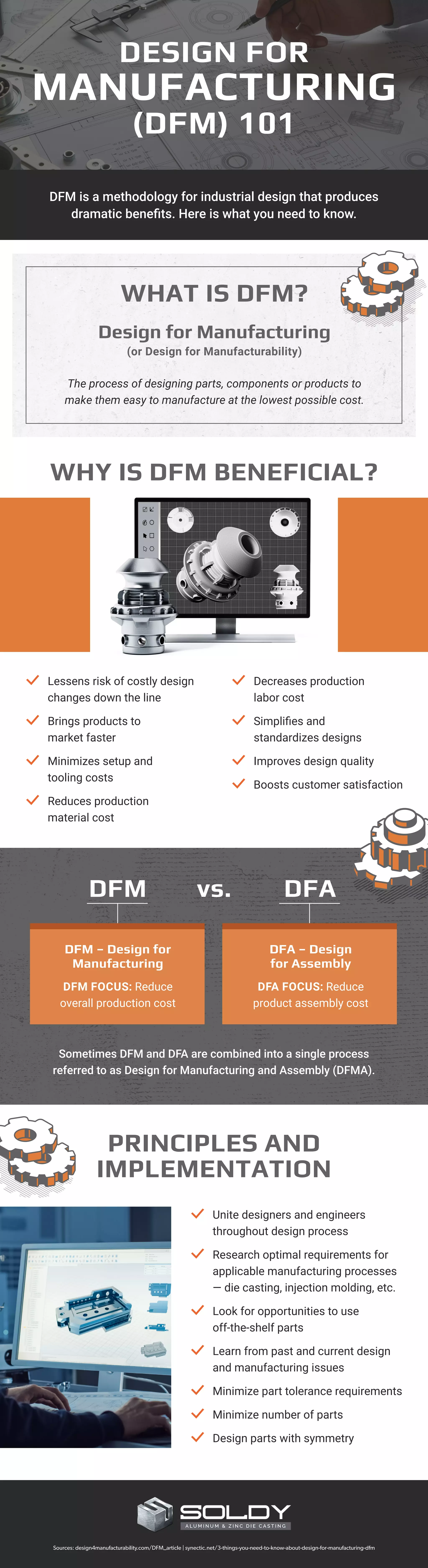

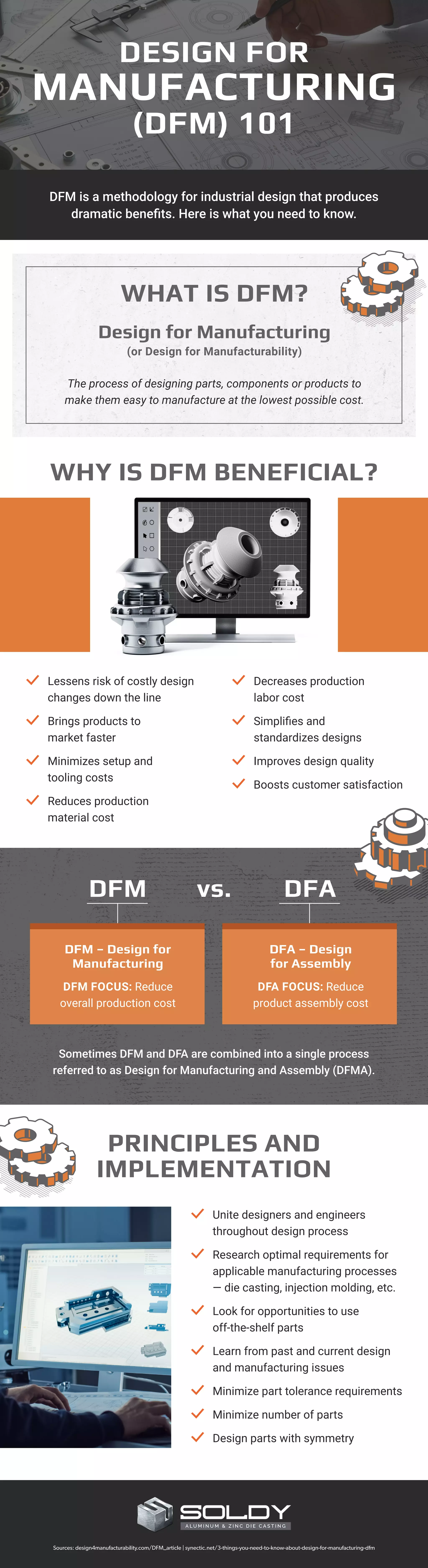

Design for Manufacturing (DFM) is a methodology aimed at optimizing industrial design to enhance manufacturability and cost-effectiveness. It reduces risks of costly design changes, accelerates time-to-market, and lowers production costs by simplifying designs and standardizing processes. DFM is often combined with Design for Assembly (DFA) into a unified approach known as design for manufacturing and assembly (DFMA), focusing on both production and assembly cost reductions.