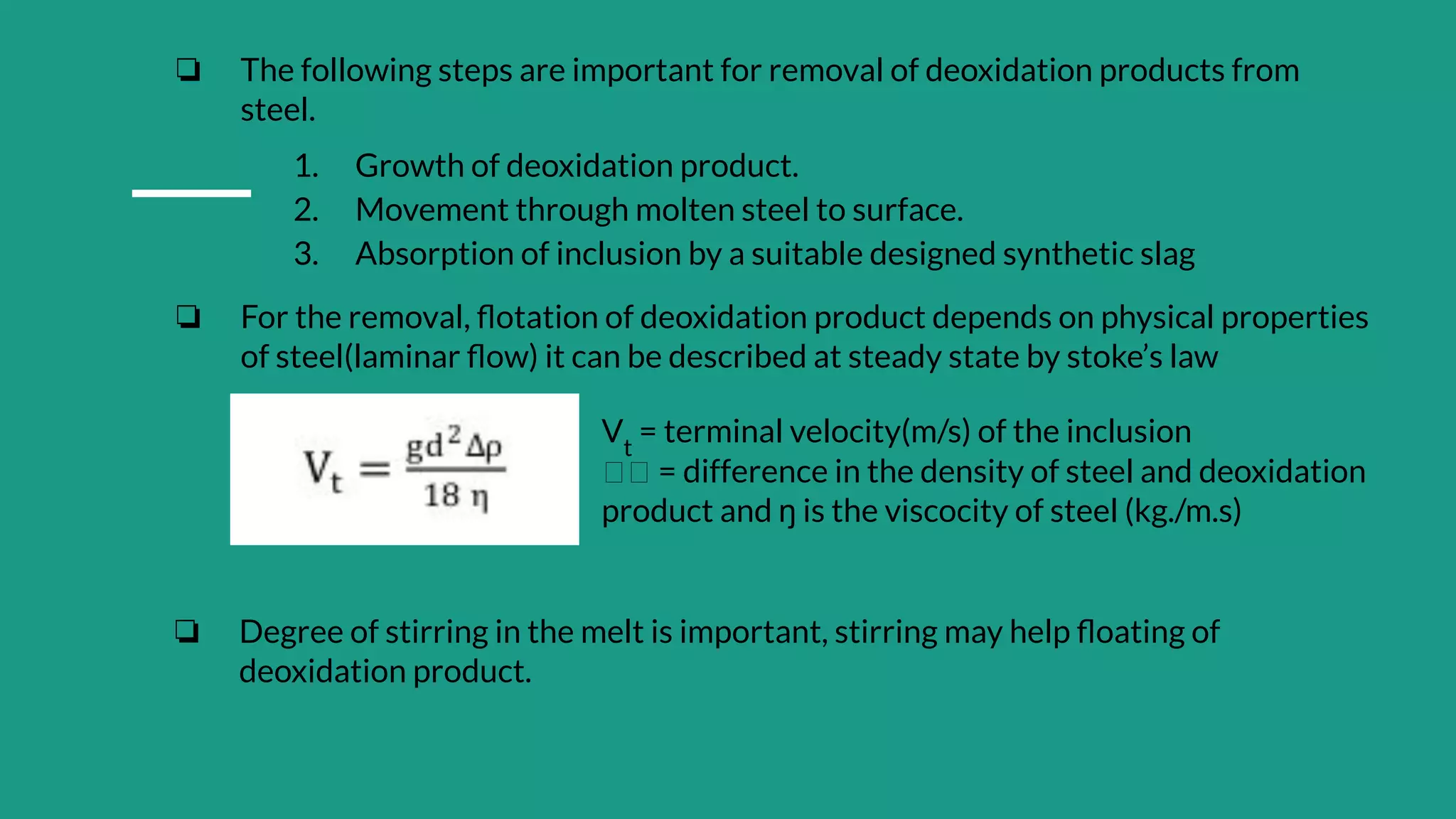

Deoxidation is the process of removing residual oxygen from refined steel to prevent defects. Sources of oxygen in steel include rust, oxygen blowing during manufacturing, slag, and atmospheric oxygen during teeming. The kinetics of deoxidation involve the dissolution of deoxidizers like aluminum, their reaction with oxygen, and the nucleation and growth of deoxidation products. Effective deoxidizers are then removed from the steel through flotation and absorption into slag. Common deoxidizers include aluminum, silicon, and manganese. Calcium injection can be used to modify inclusions and produce cleaner steels.