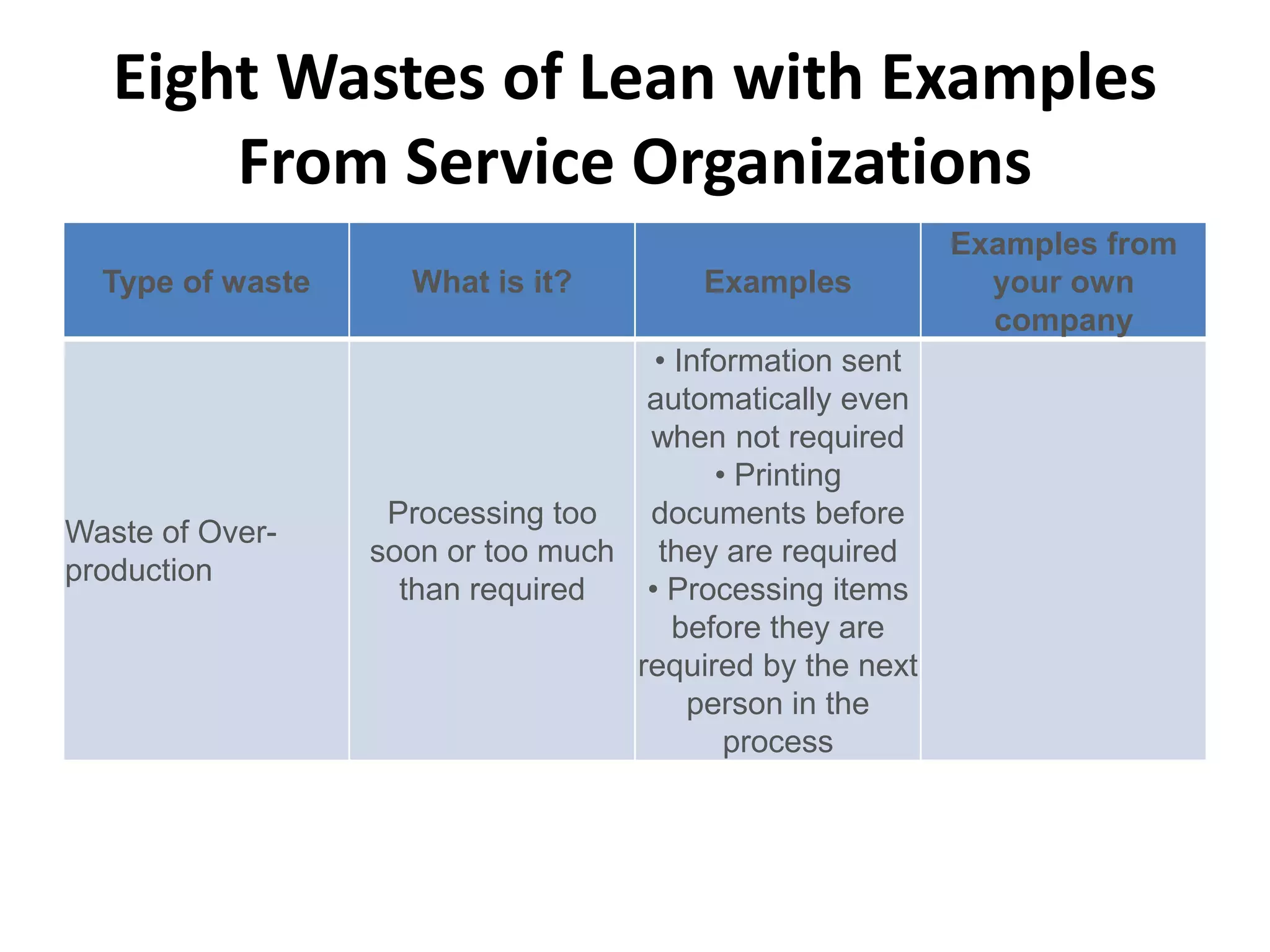

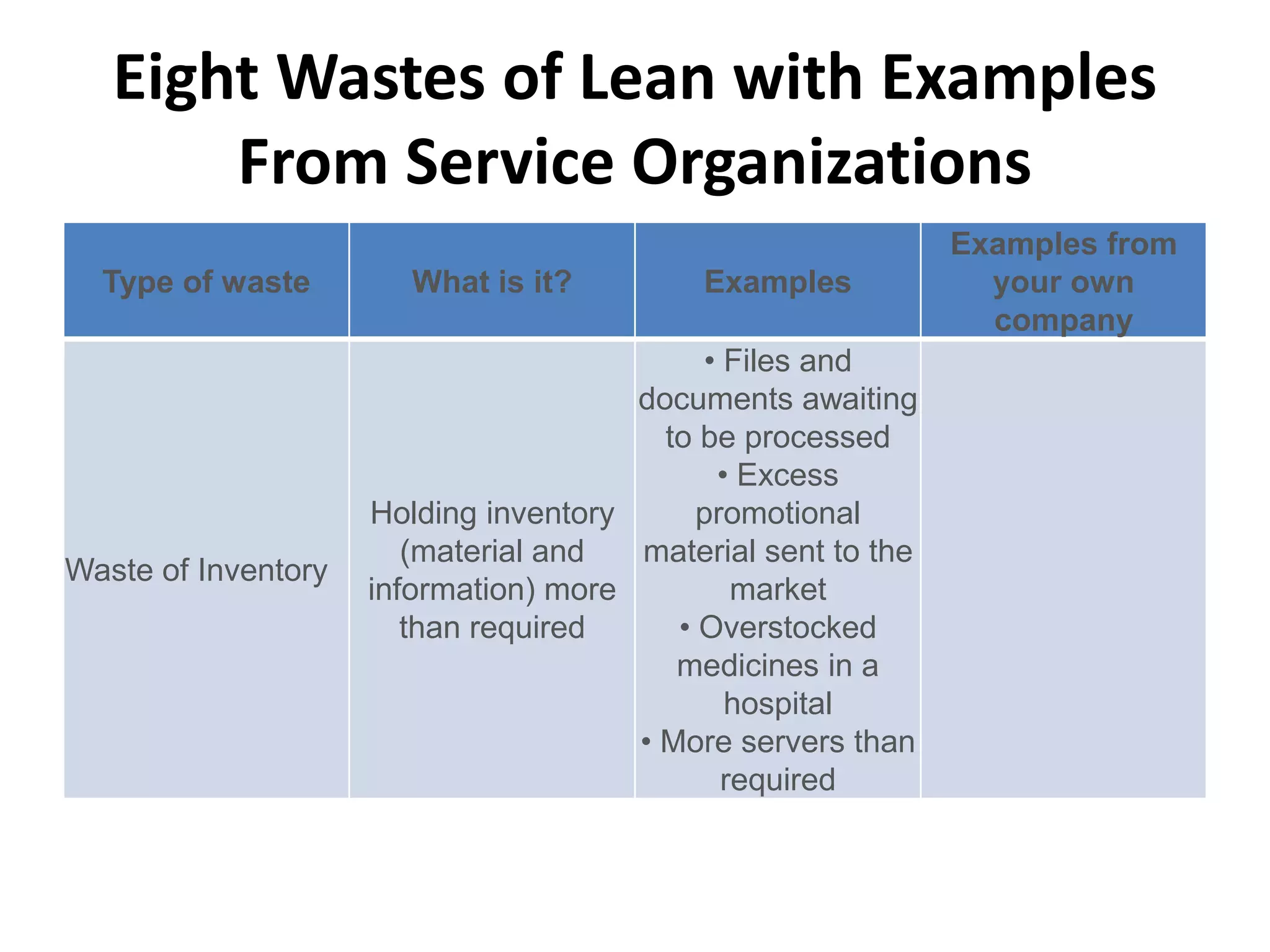

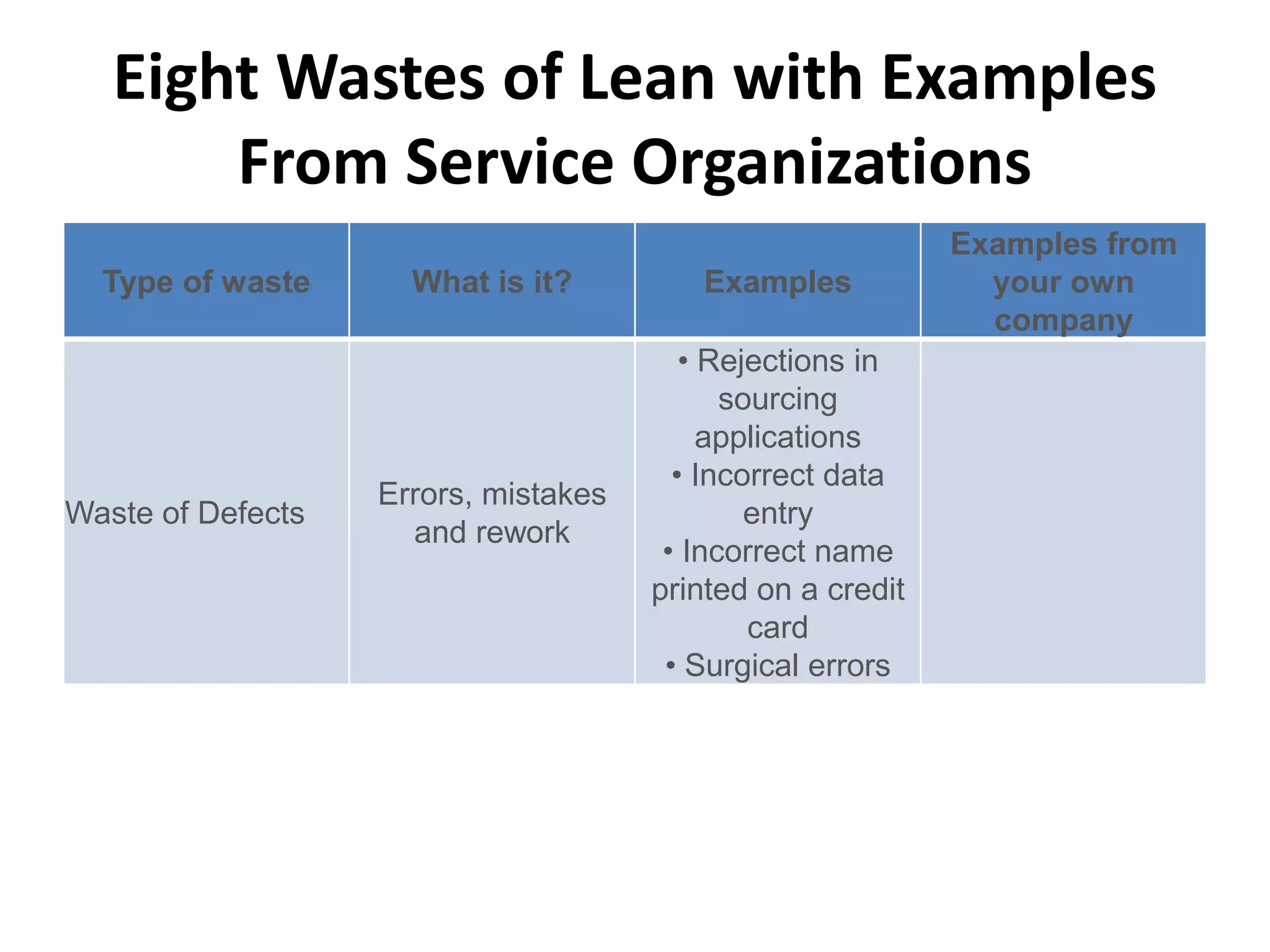

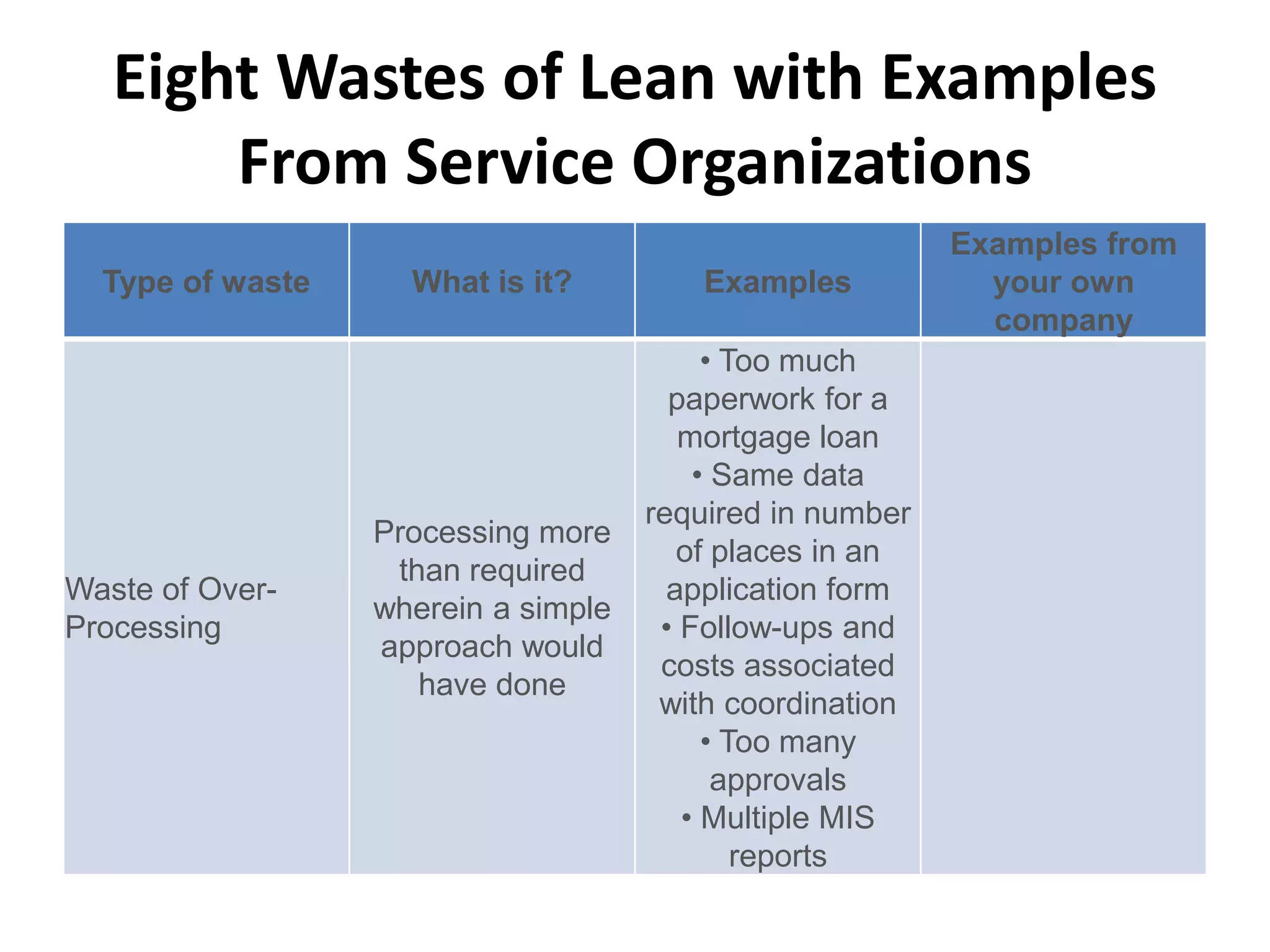

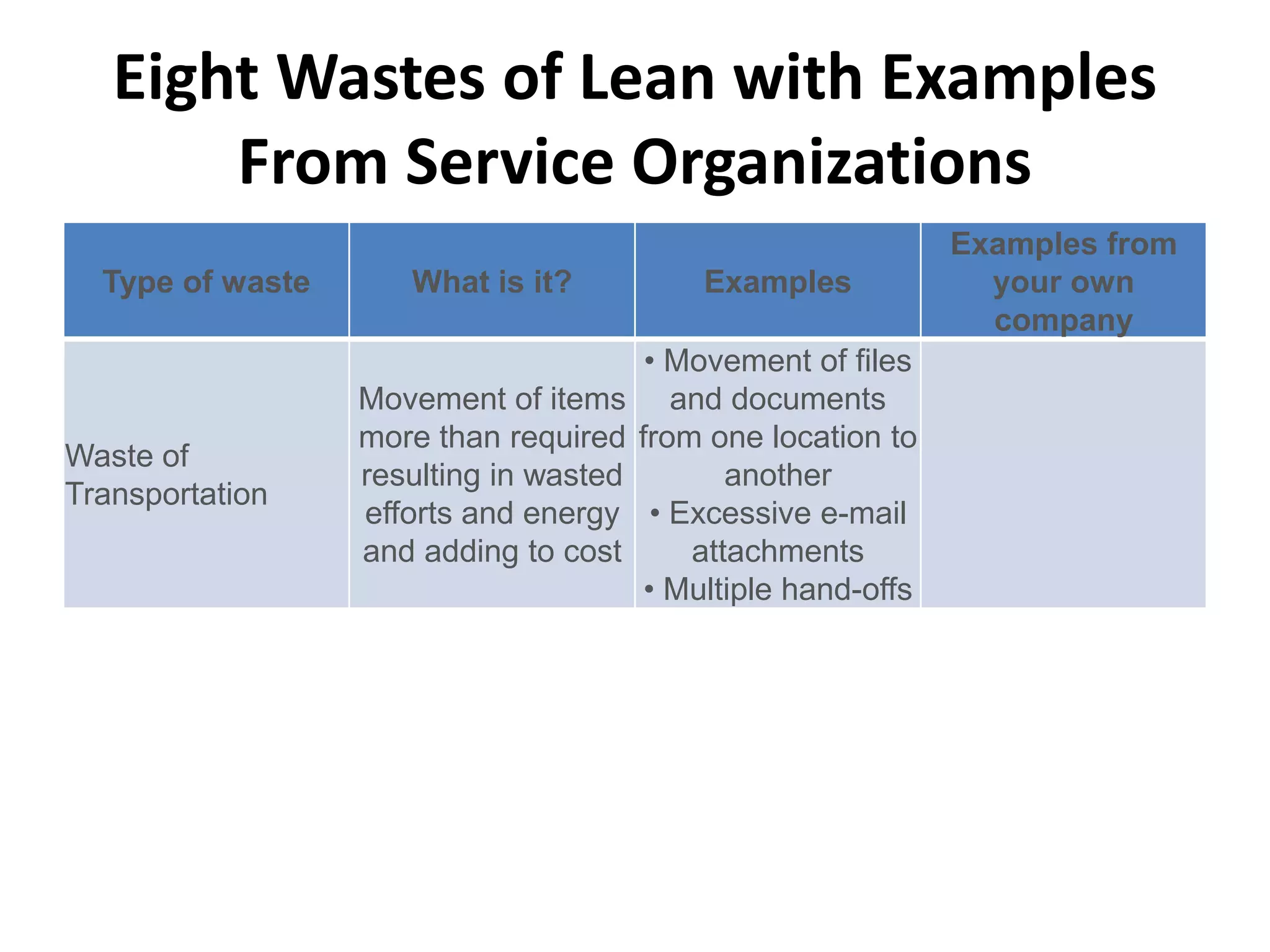

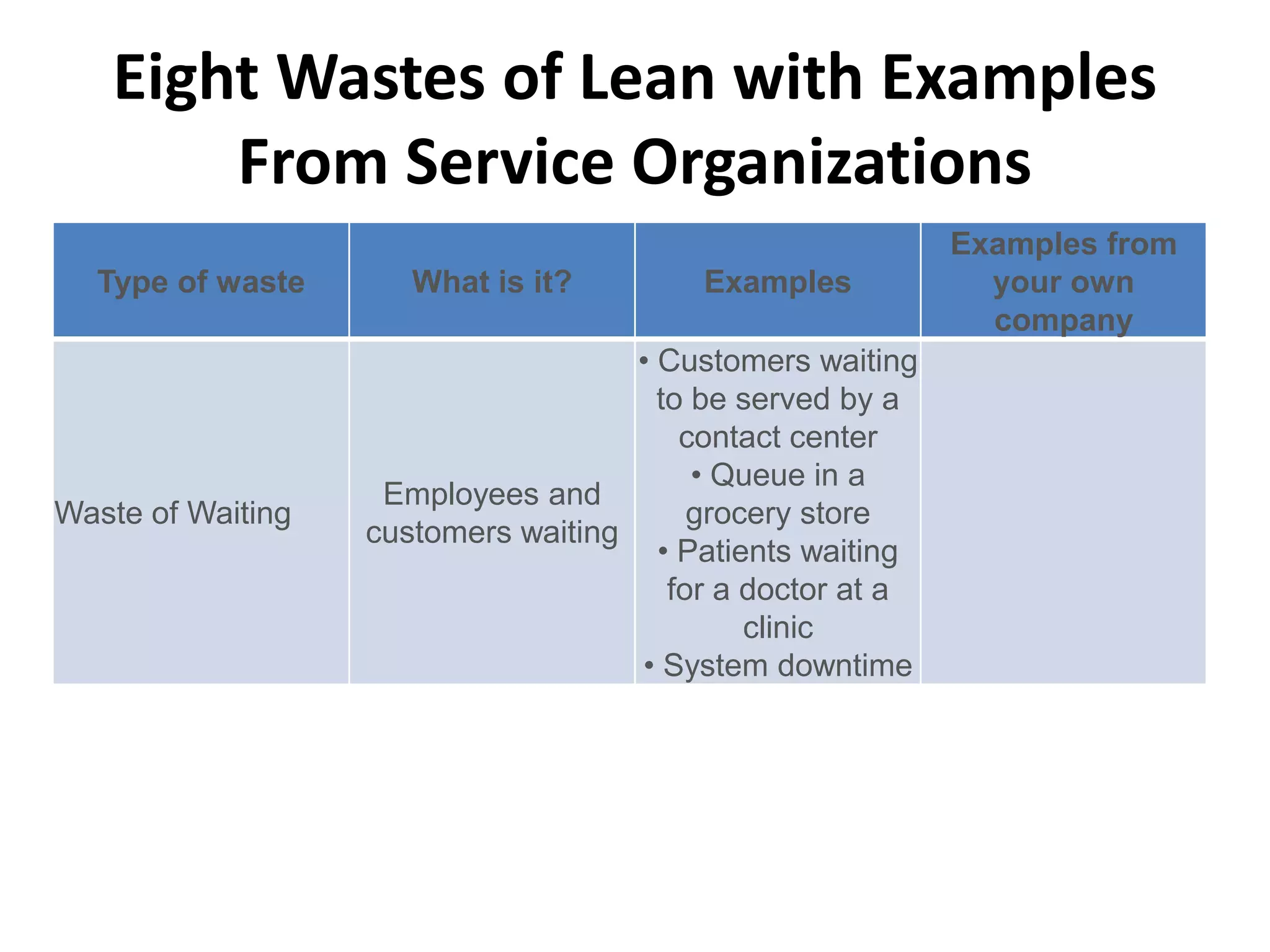

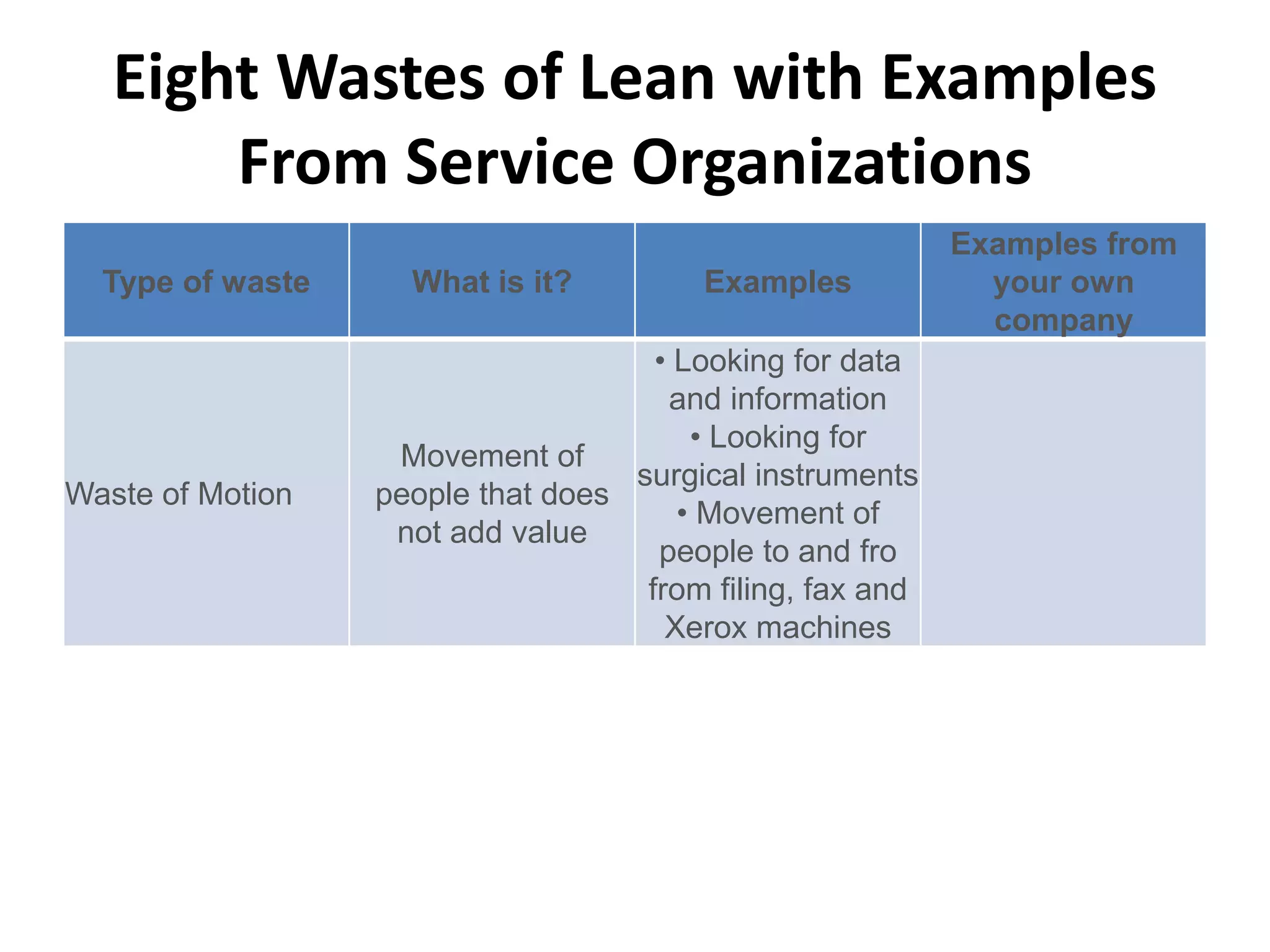

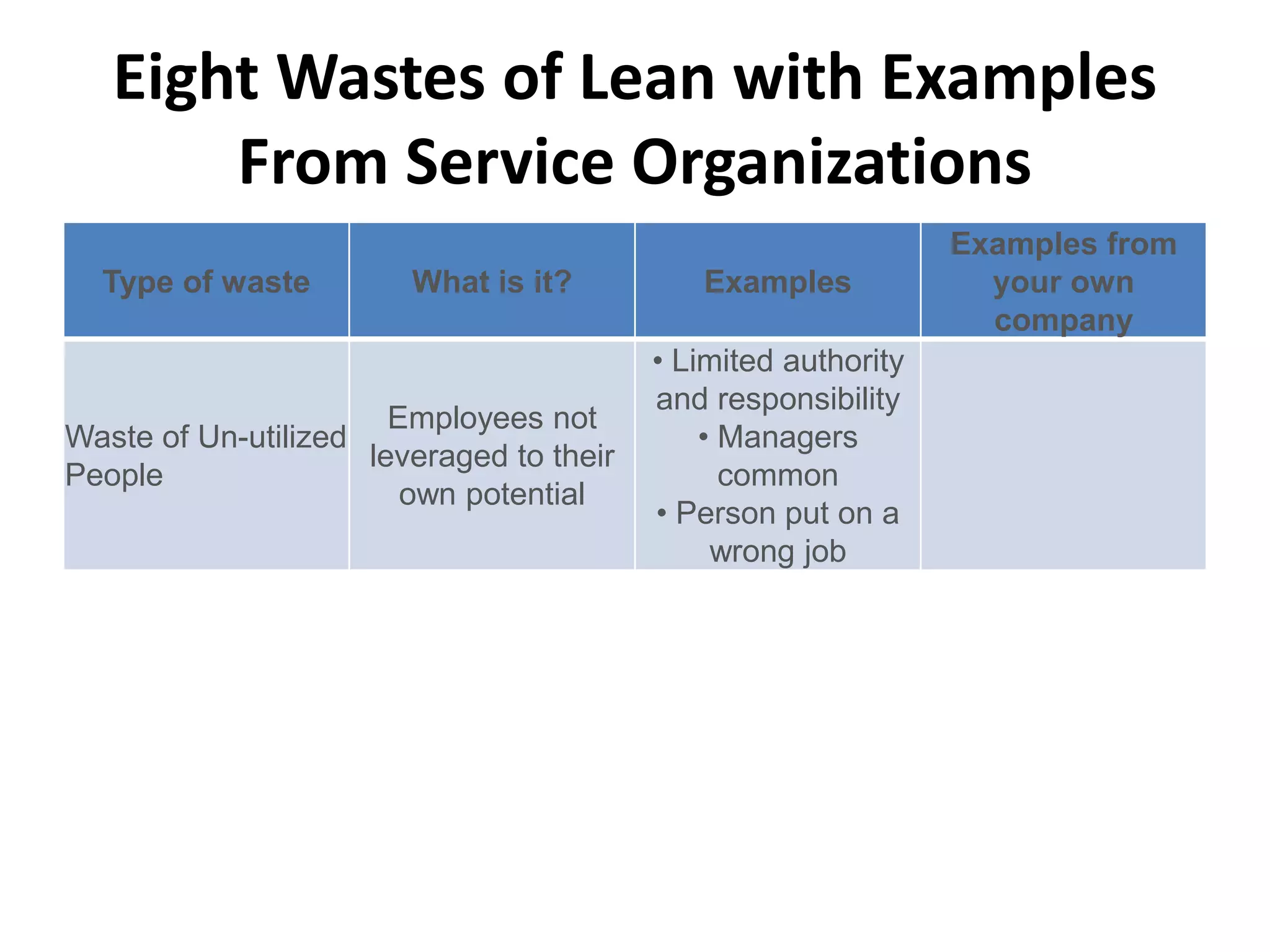

Anything that does not add value to the customer is considered waste. The eight wastes of lean identified by Taichi Ohno, including transportation, inventory, motion, waiting, overproduction, overprocessing, defects, and unused employee creativity, apply not just to manufacturing but also to service organizations. Understanding and identifying waste is important for dissecting processes and driving lean transformation in services, where up to 95% of activities may be non-value added. Value stream mapping is a useful tool for uncovering hard to see wastes in service processes.