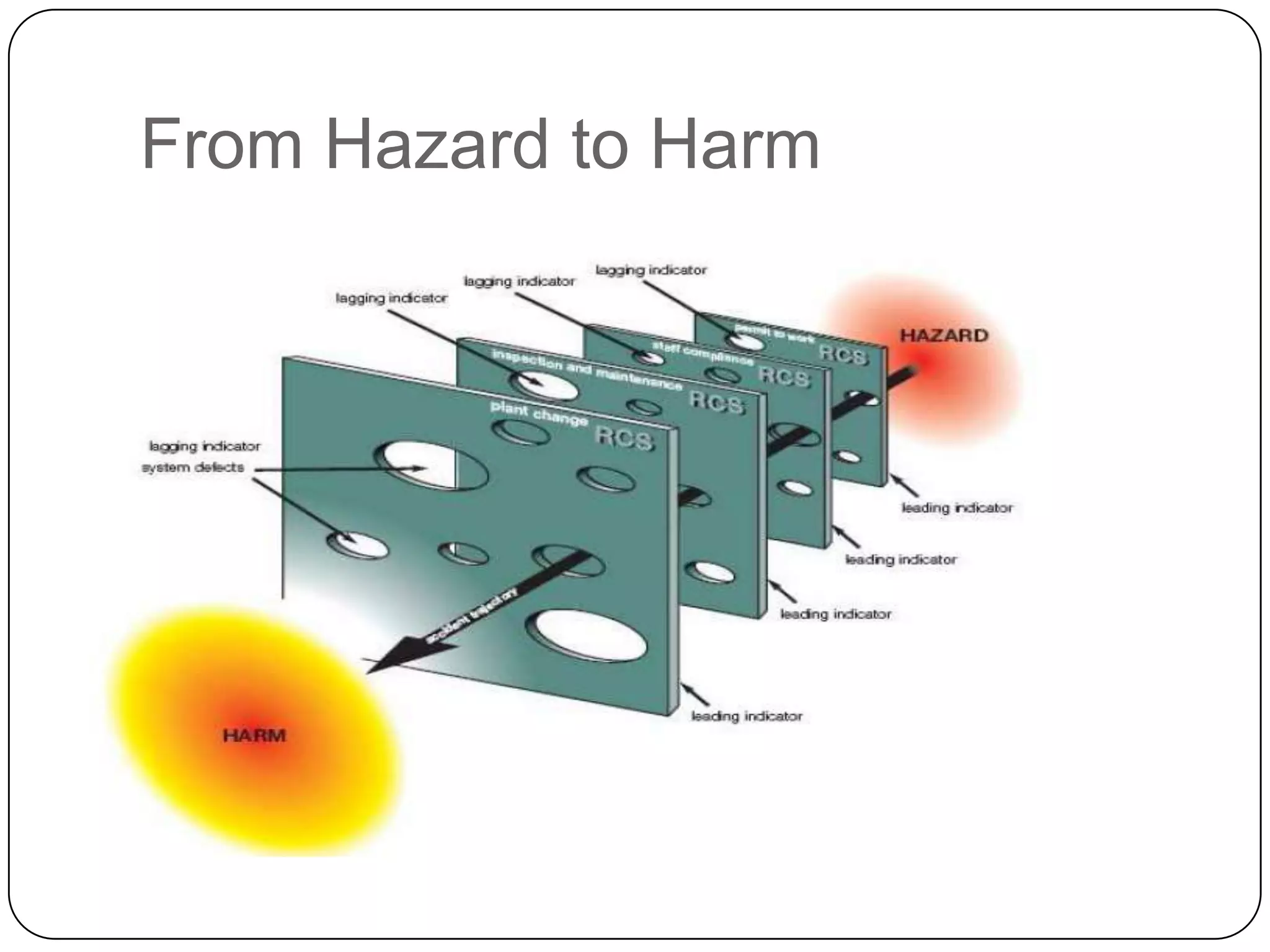

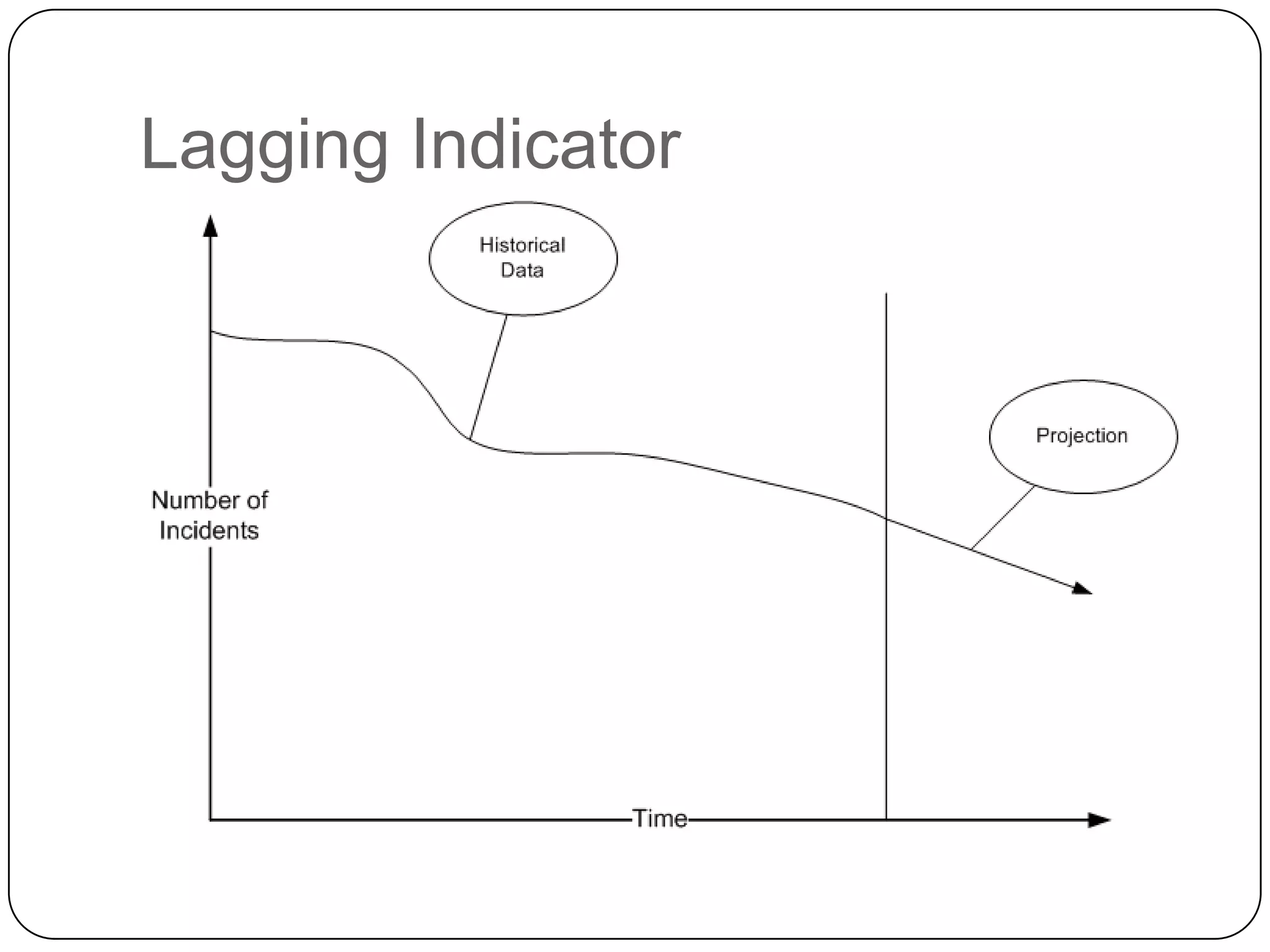

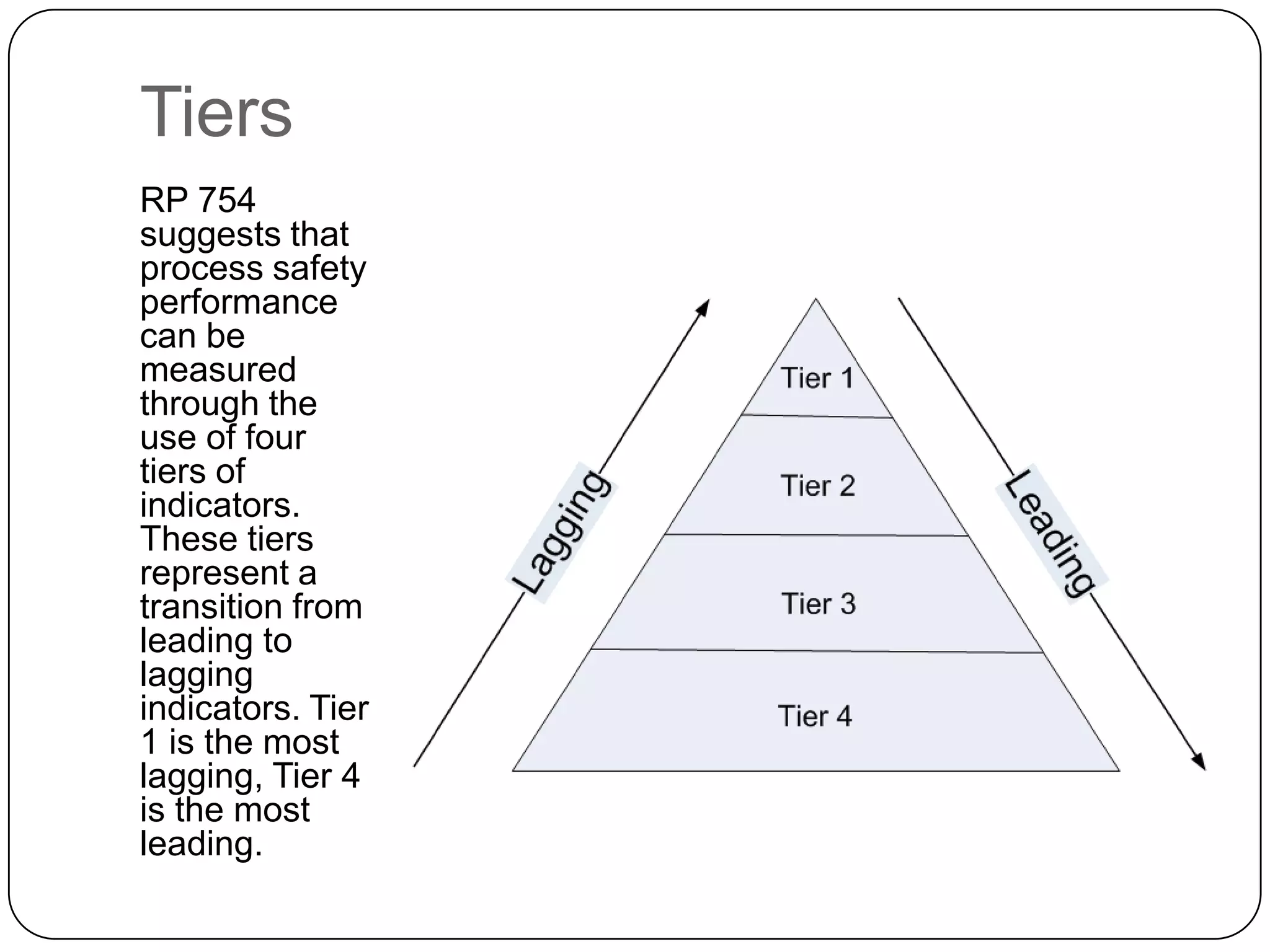

This document discusses key performance indicators (KPIs) for measuring safety performance, including lagging and leading indicators. It describes lagging indicators like recordable injuries and spills that measure past performance, as well as leading indicators like safety inspections and trainings that predict future safety. The document outlines a tiered framework from API RP 754 for indicators, ranging from infrequent Tier 1 events with highest consequences to more common Tier 4 measures of management system performance. Selection of the right mix of lagging and leading KPIs is important for continuous safety improvement.

![Tiers

Tiers 3 and 4 are intended for internal use at

individual sites.

Quantification is measured through use of the

Process Safety Event (PSE) rate, which is

calculated as follows:

PSE Rate = [Total PSE Count x 200,000] / Total

Workforce Hours

Each Tier has its own PSE rate.](https://image.slidesharecdn.com/definingkpi-unsafeactsandconditionsandnearmiss2-130521064400-phpapp02/75/Defining-kpi-in-terms-of-unsafe-acts-conditions-and-near-miss-22-2048.jpg)