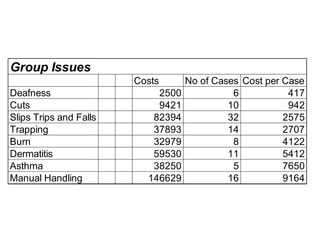

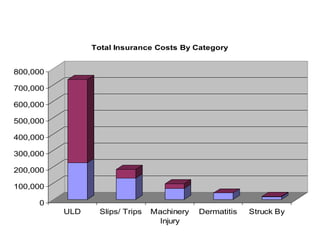

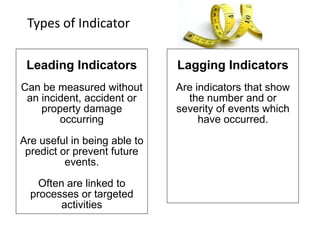

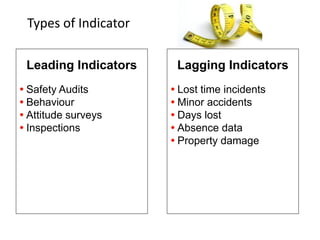

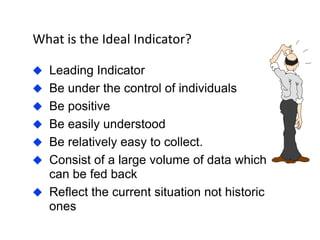

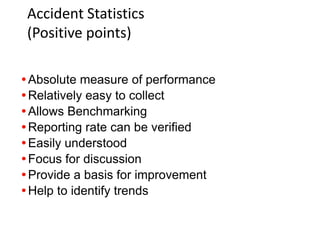

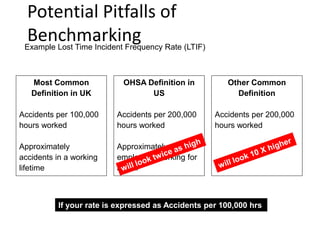

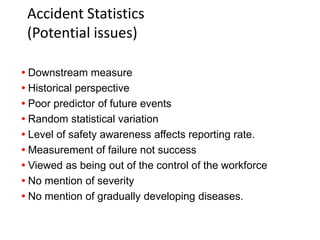

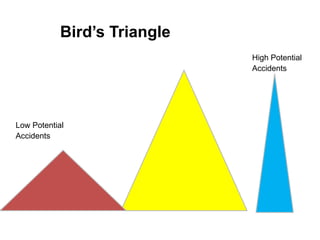

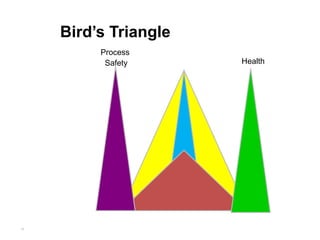

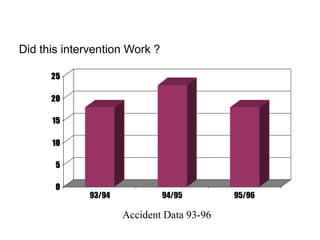

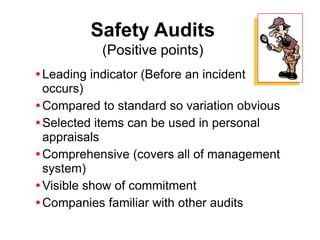

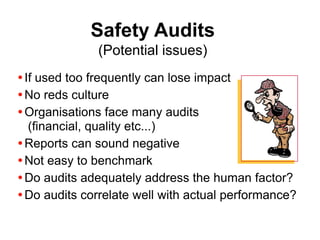

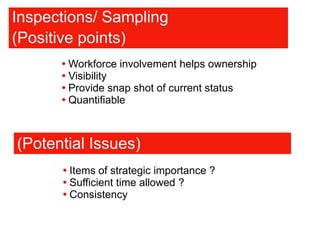

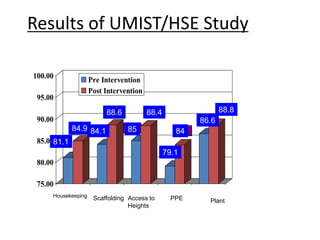

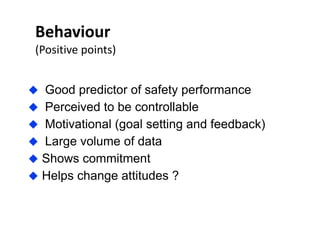

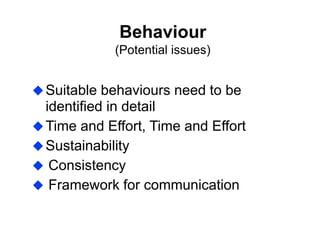

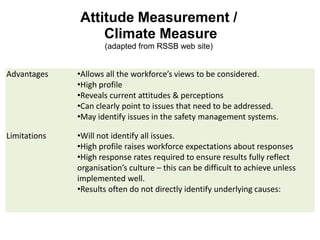

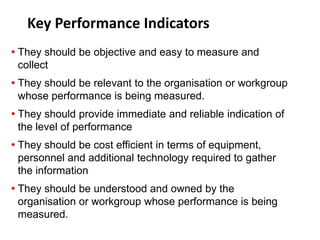

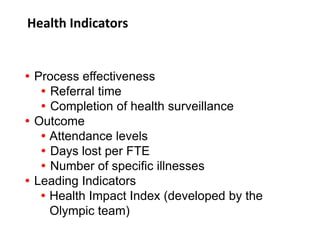

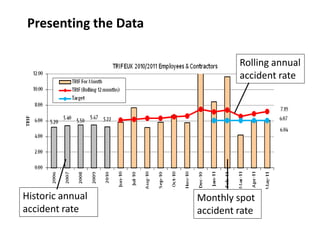

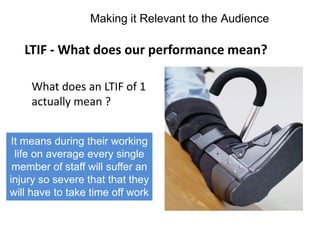

This document discusses indicators of performance in health and safety management. It begins by explaining the purposes of indicators, which include monitoring performance, raising awareness of issues, and using in incentive programs. The main types of indicators discussed are leading and lagging. Leading indicators predict future events while lagging indicators show past events. Common indicators mentioned include safety audits, behaviors, attitudes, inspections, accidents, and process safety. The document also covers pros and cons of different indicators, presenting data, and health indicators.