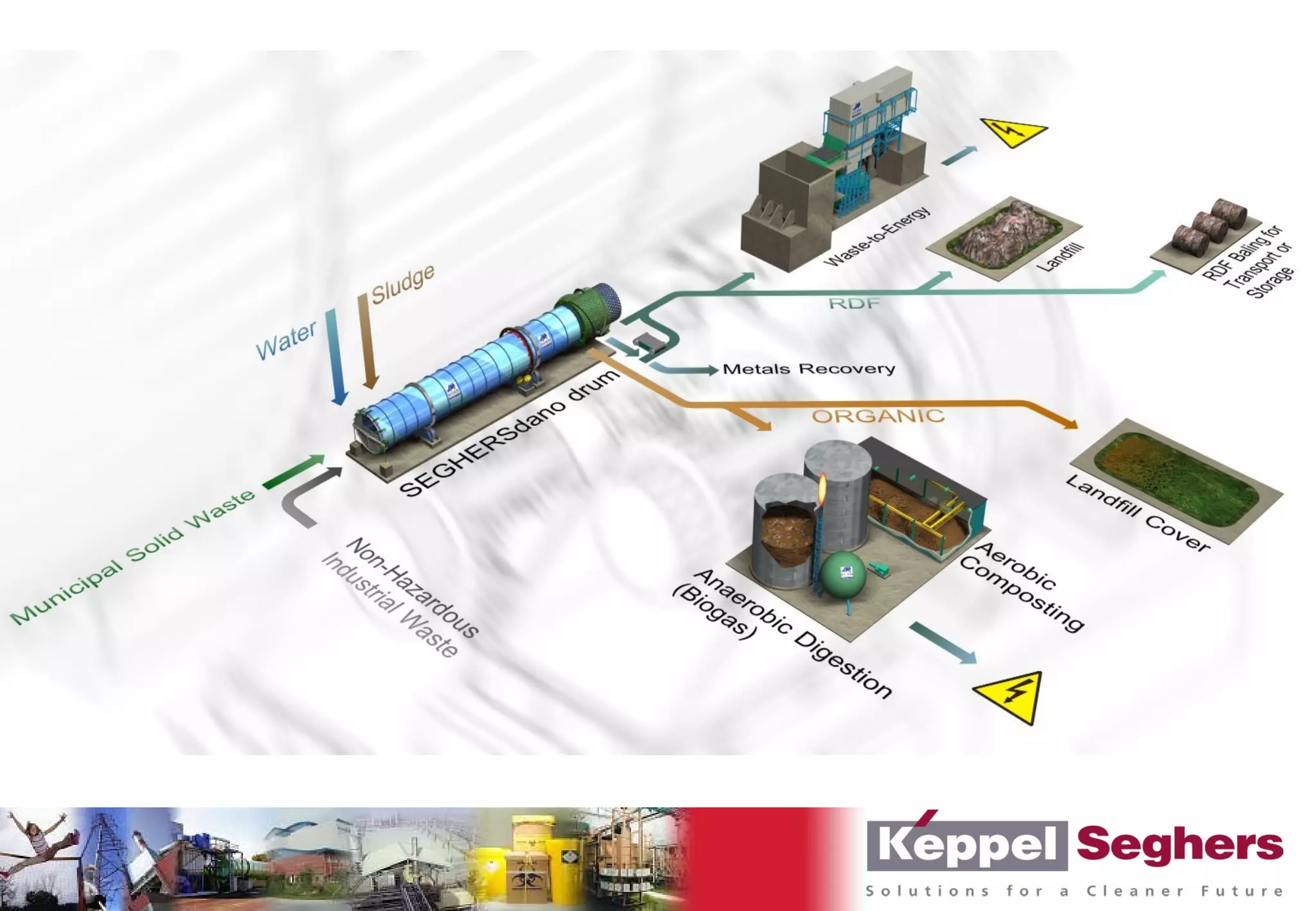

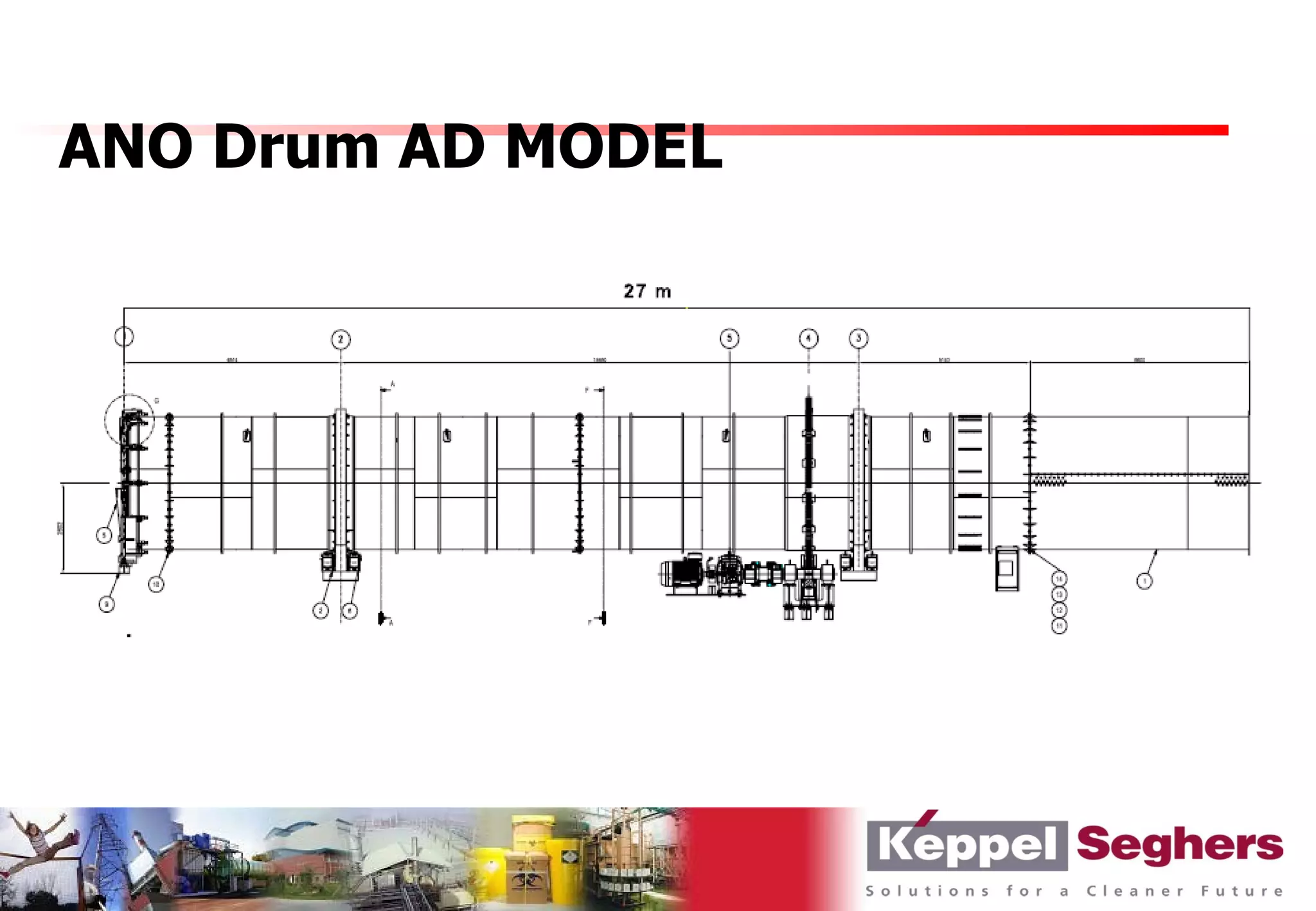

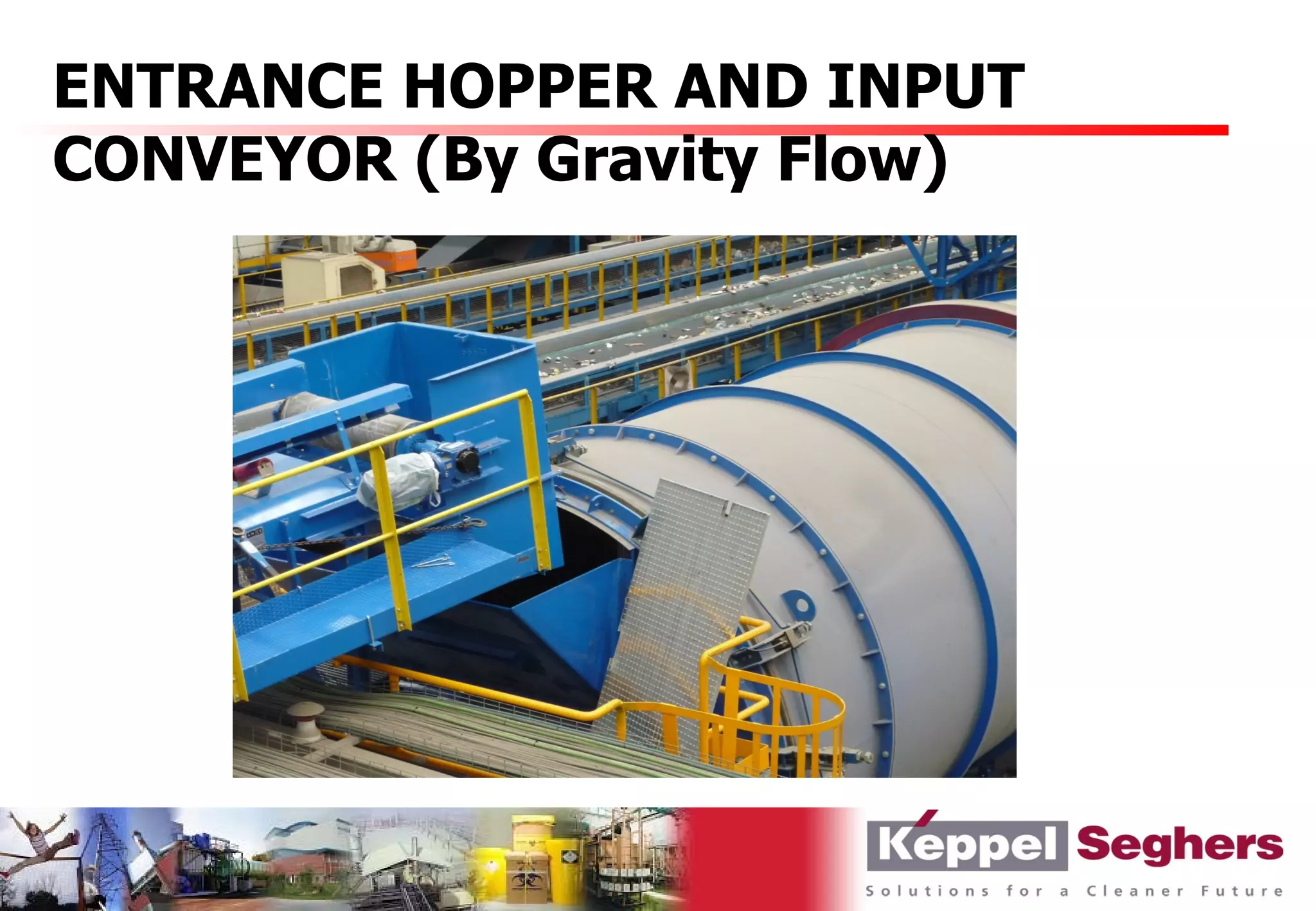

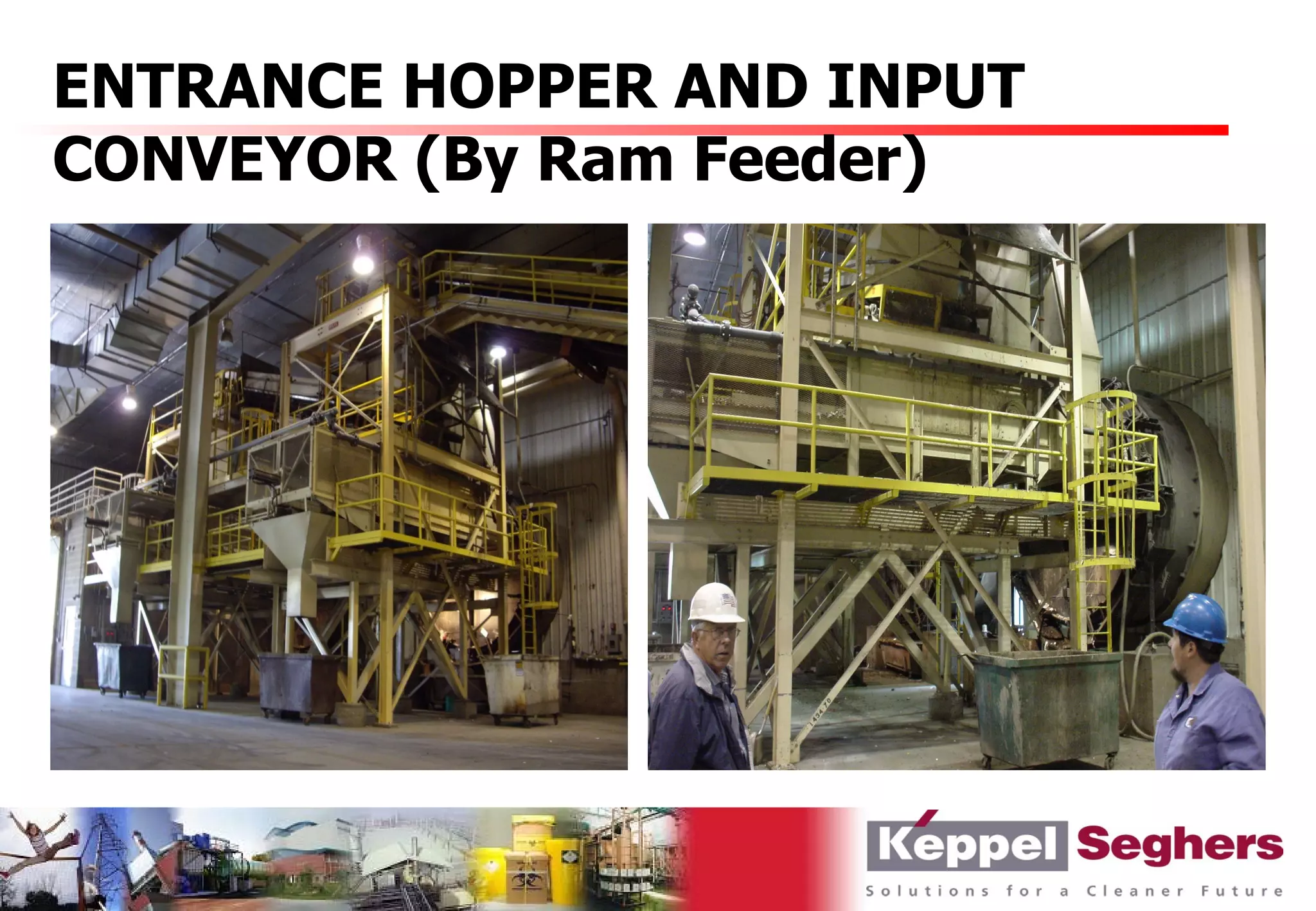

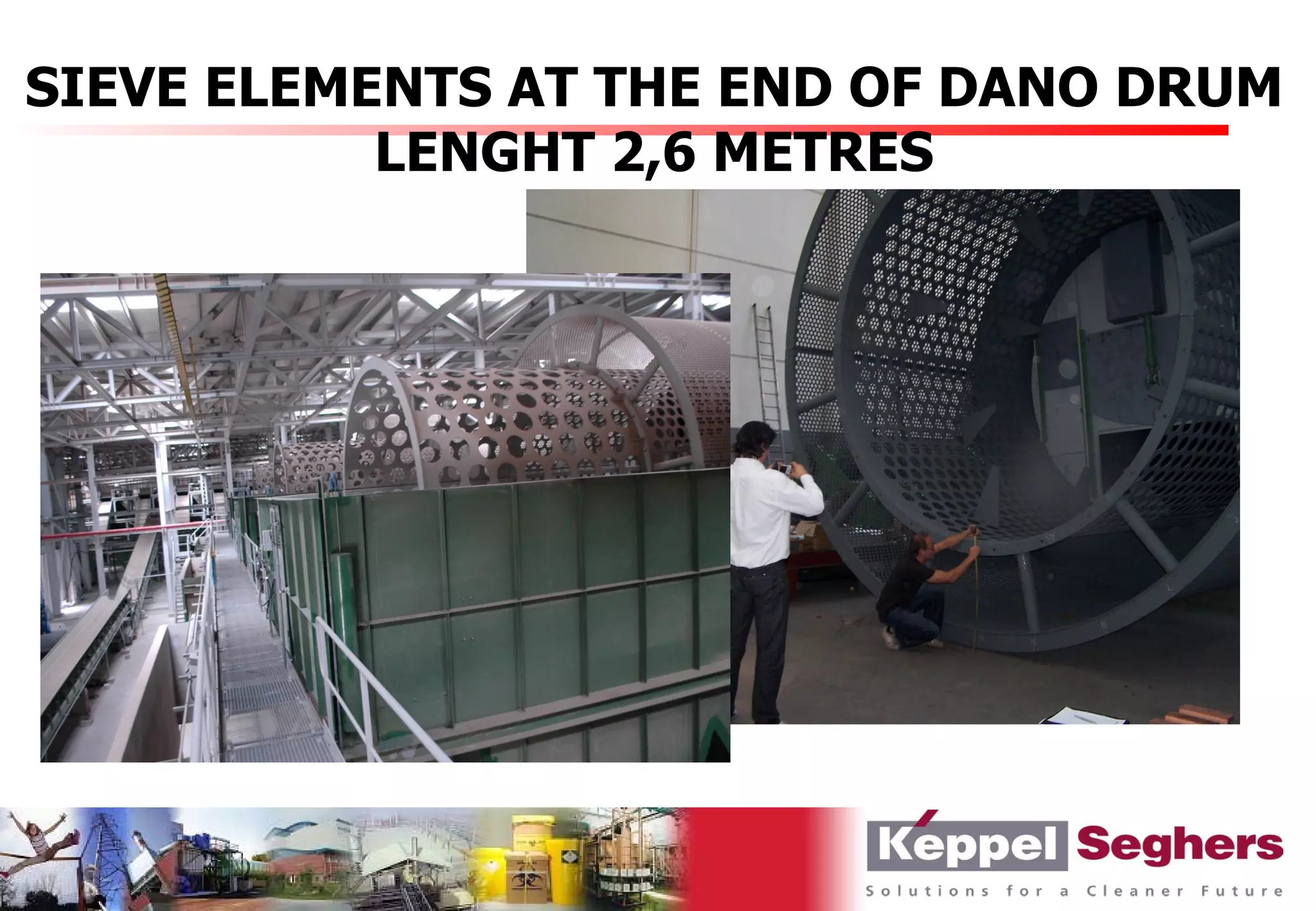

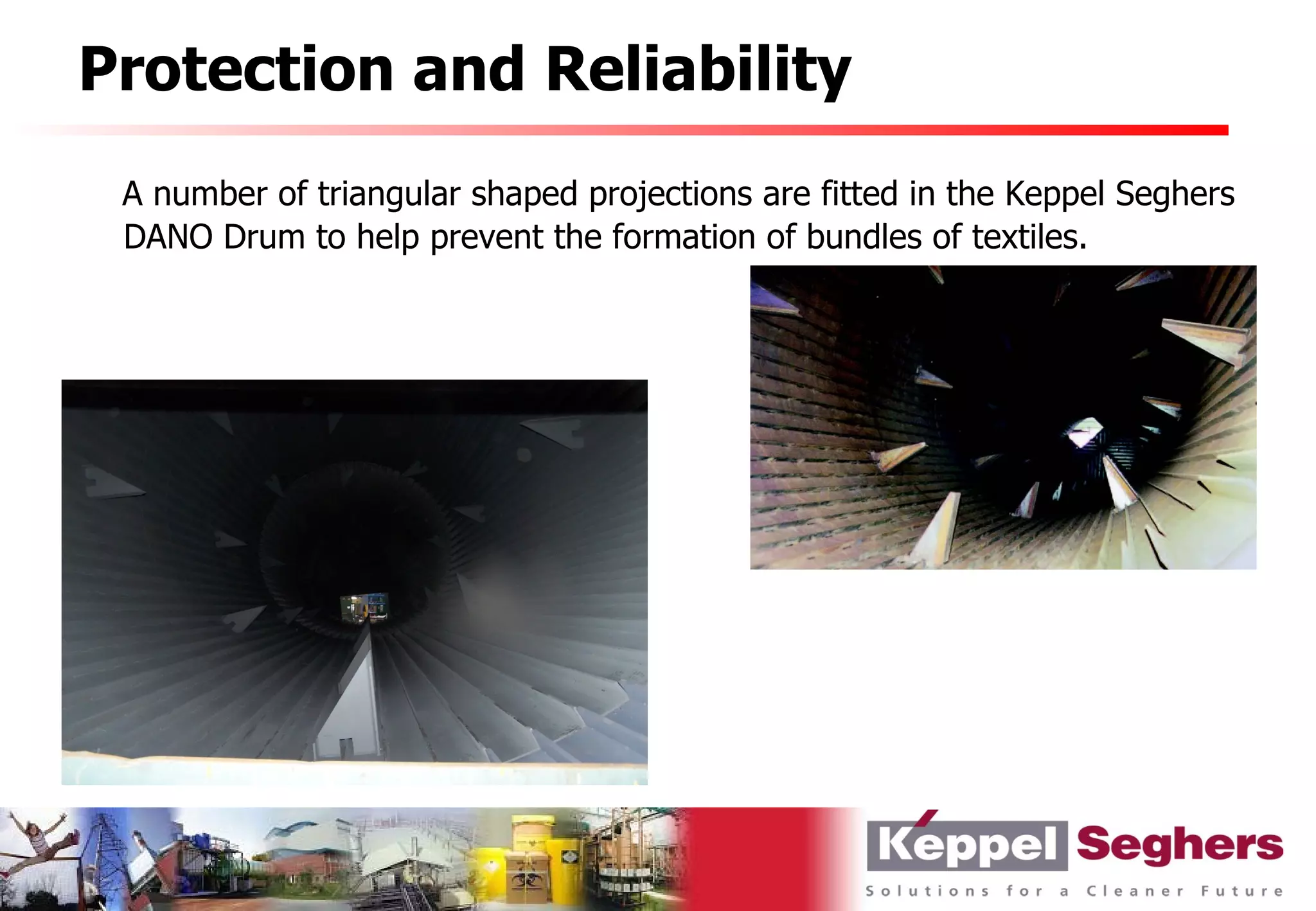

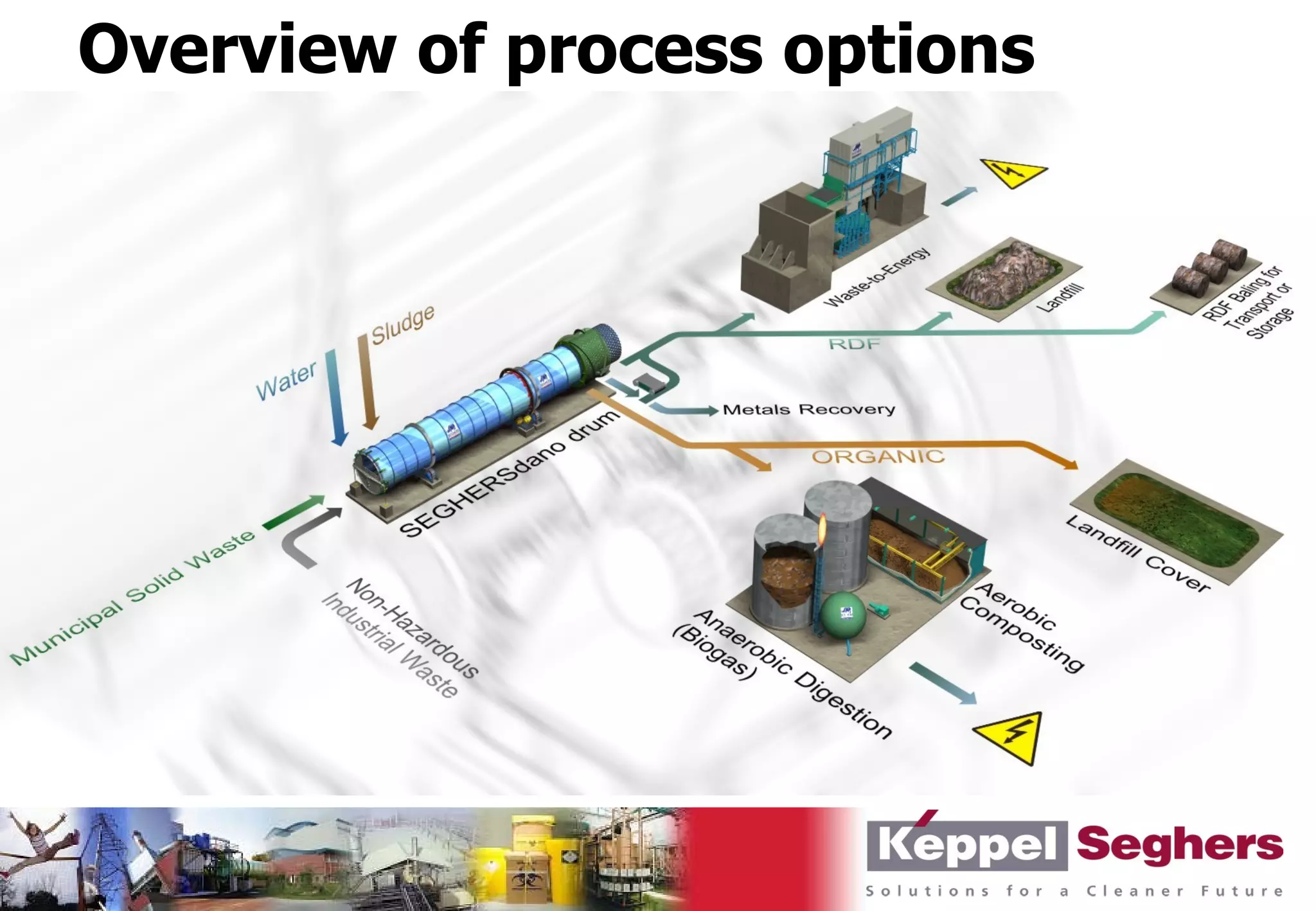

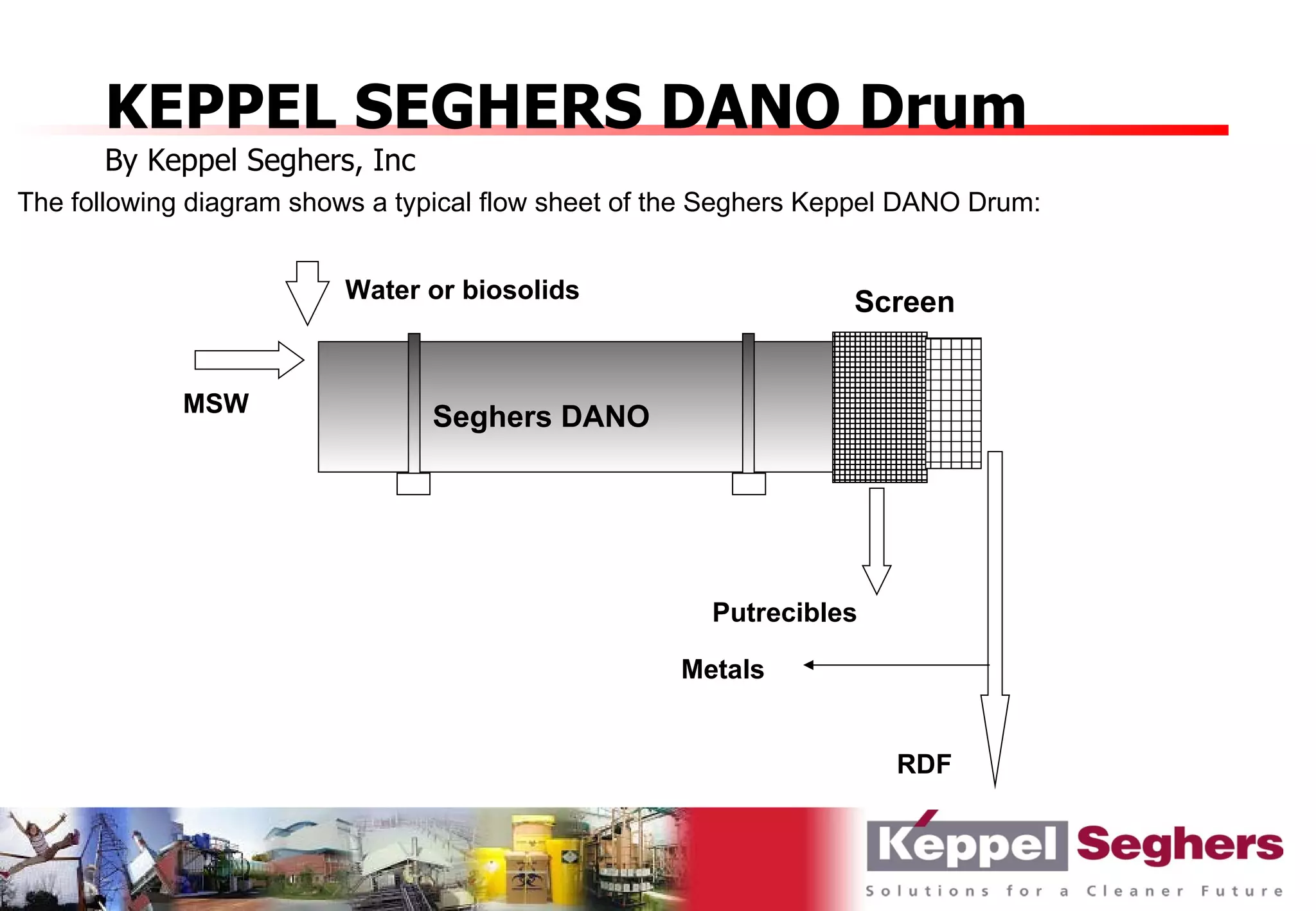

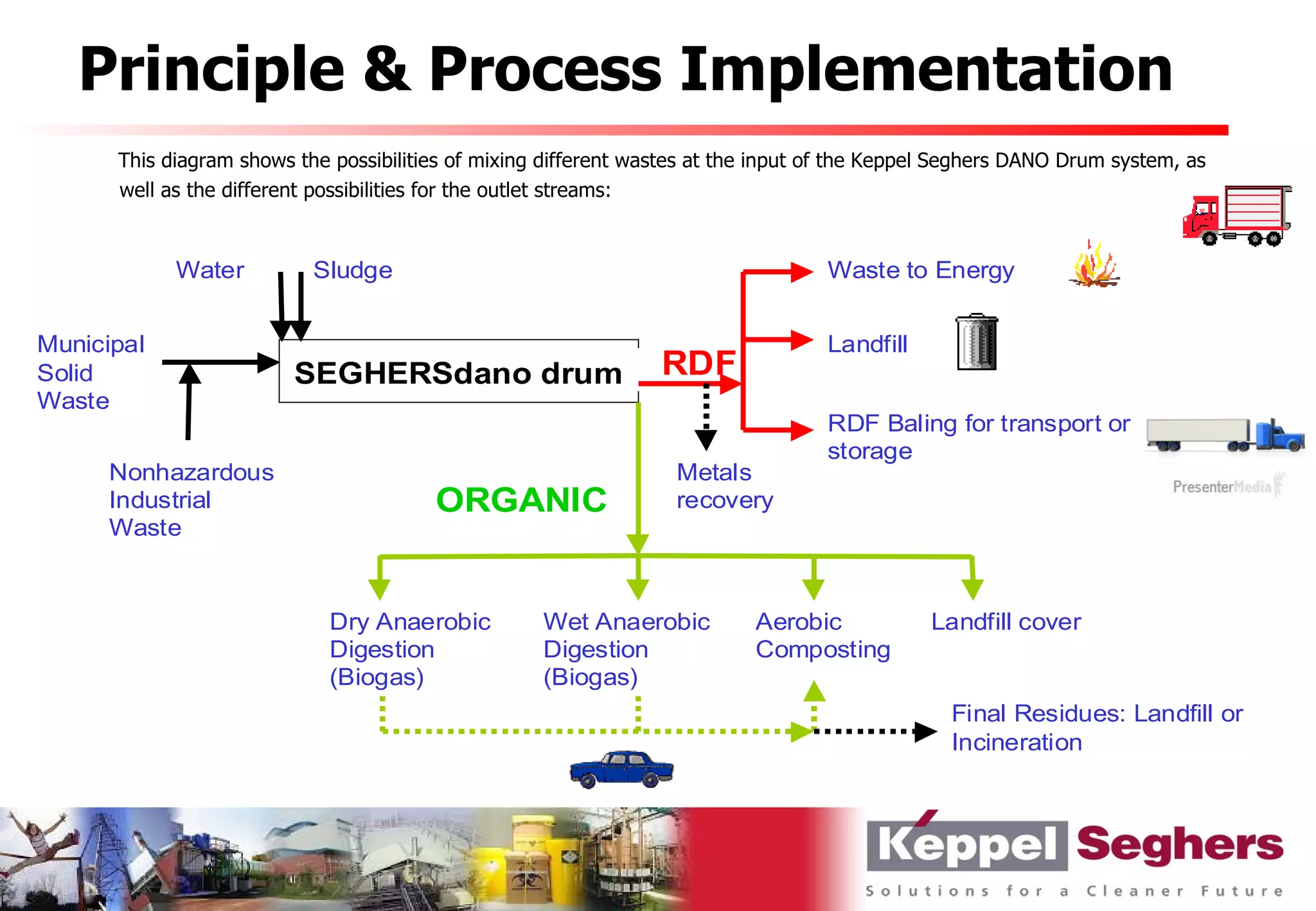

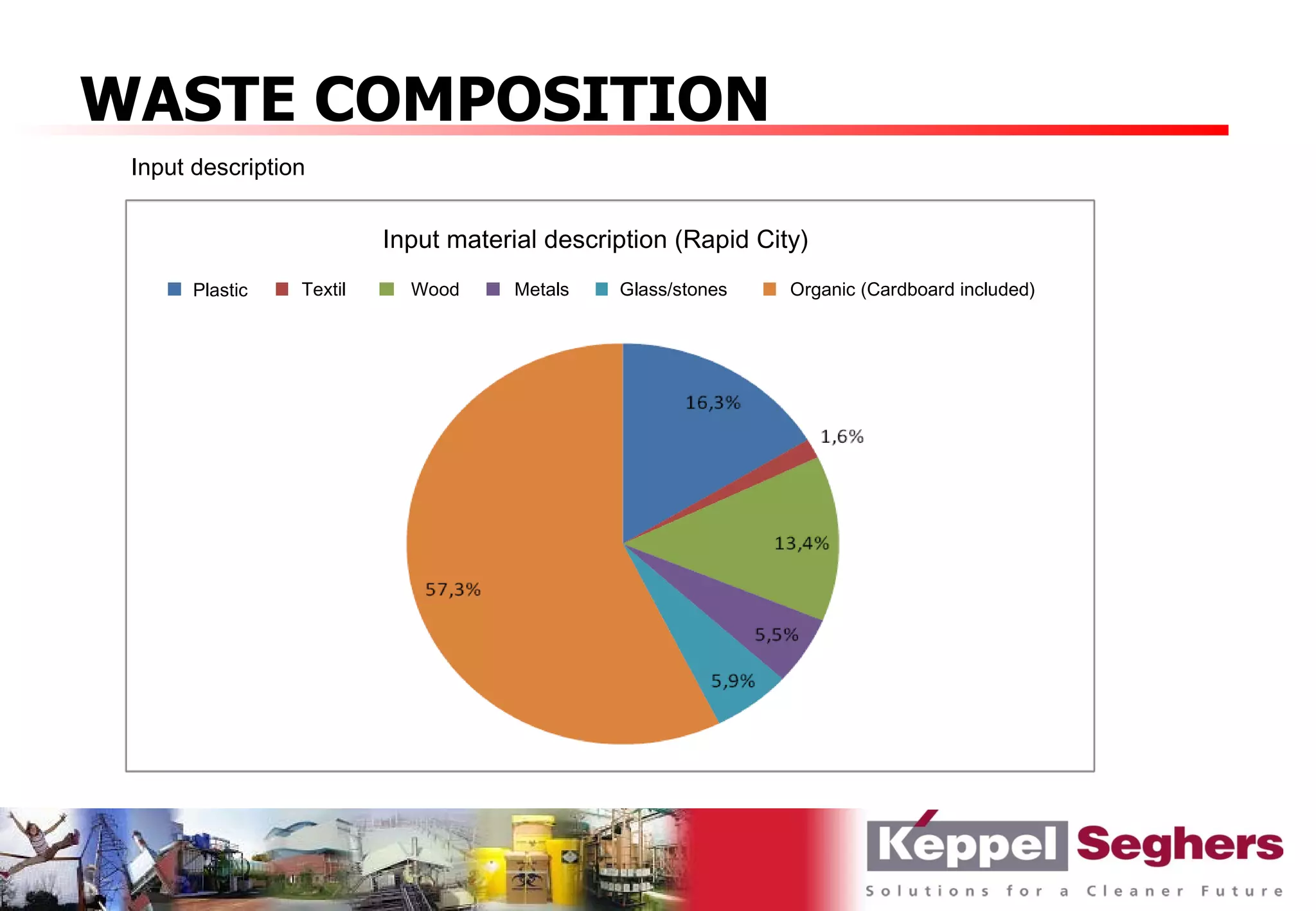

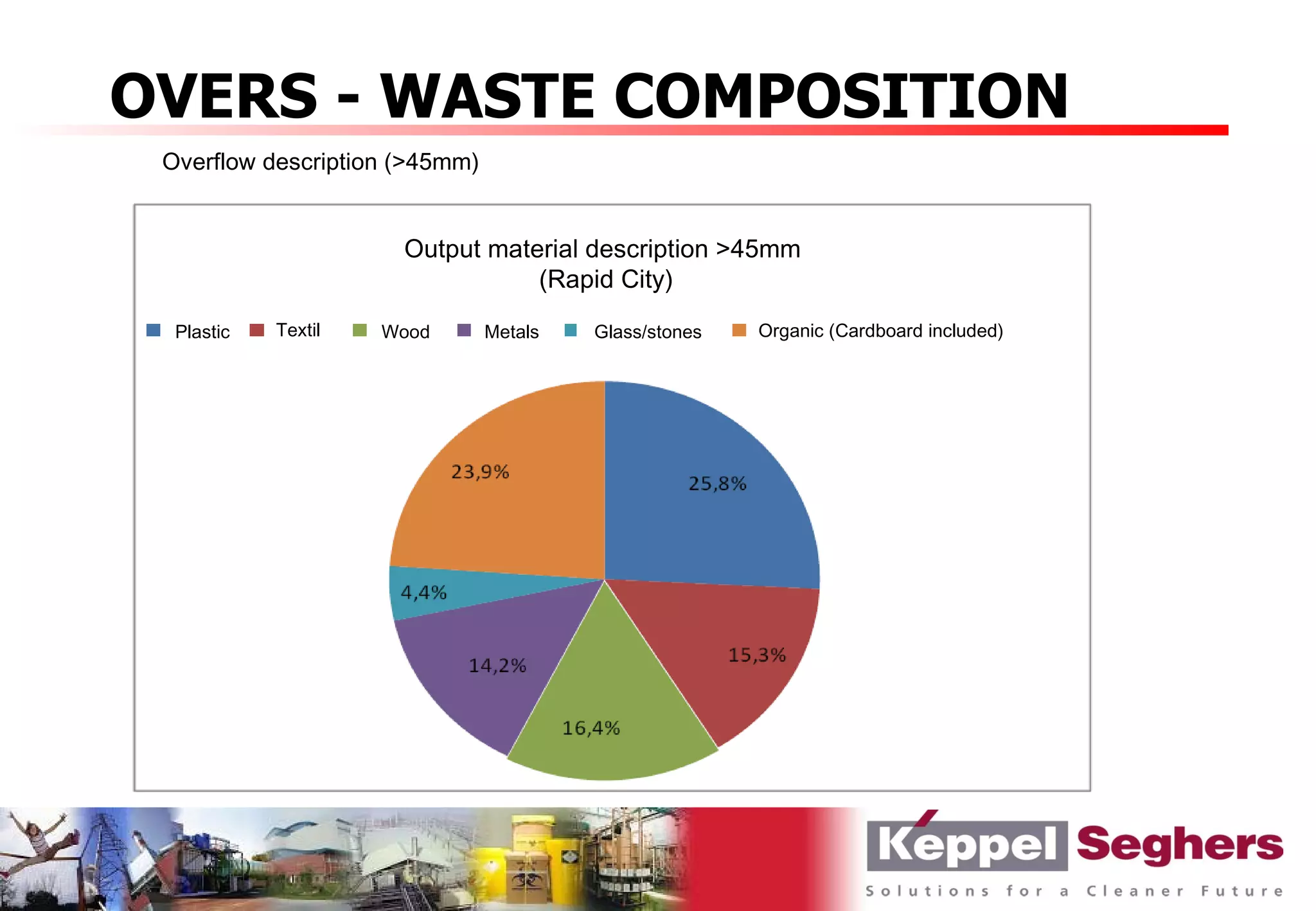

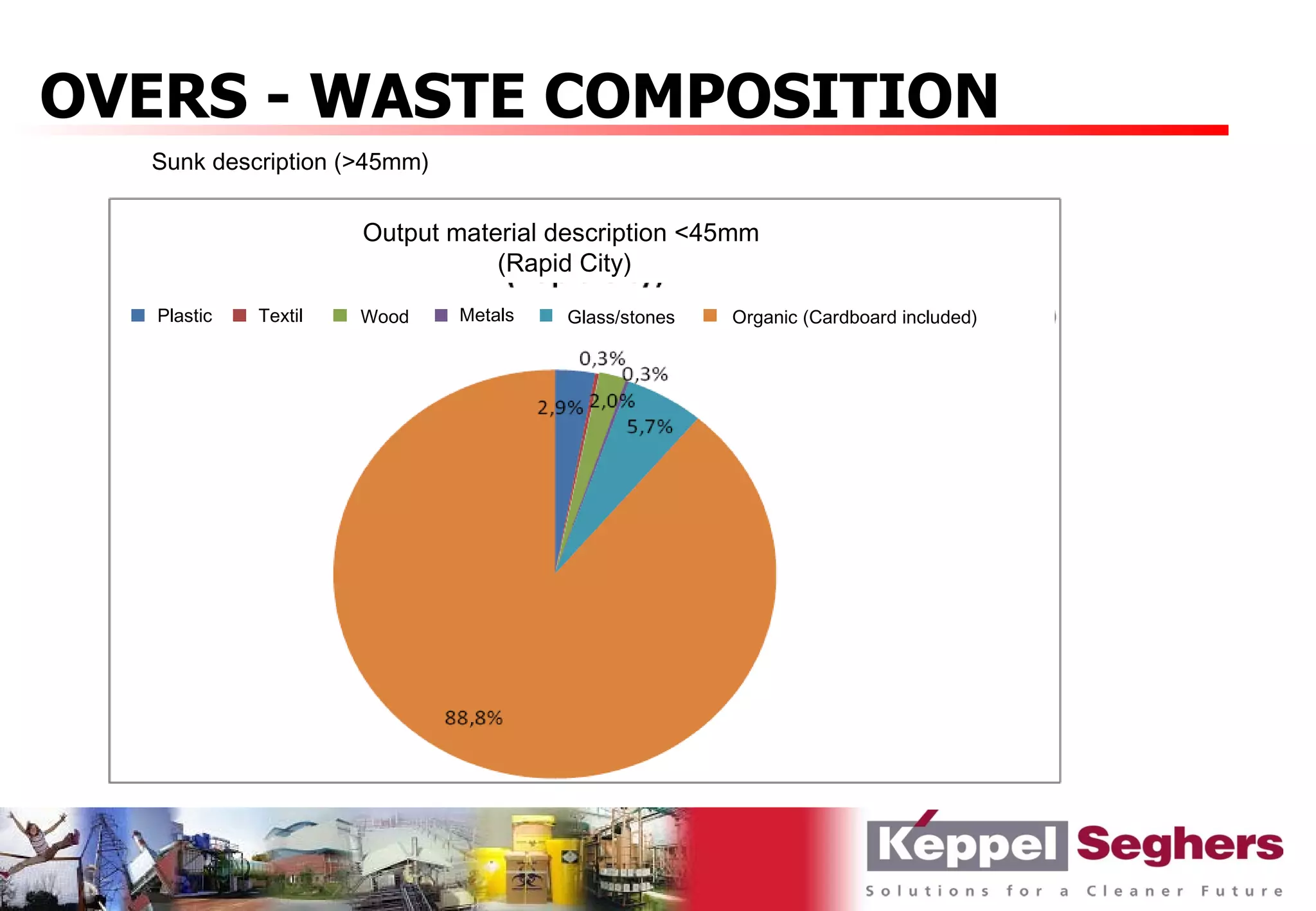

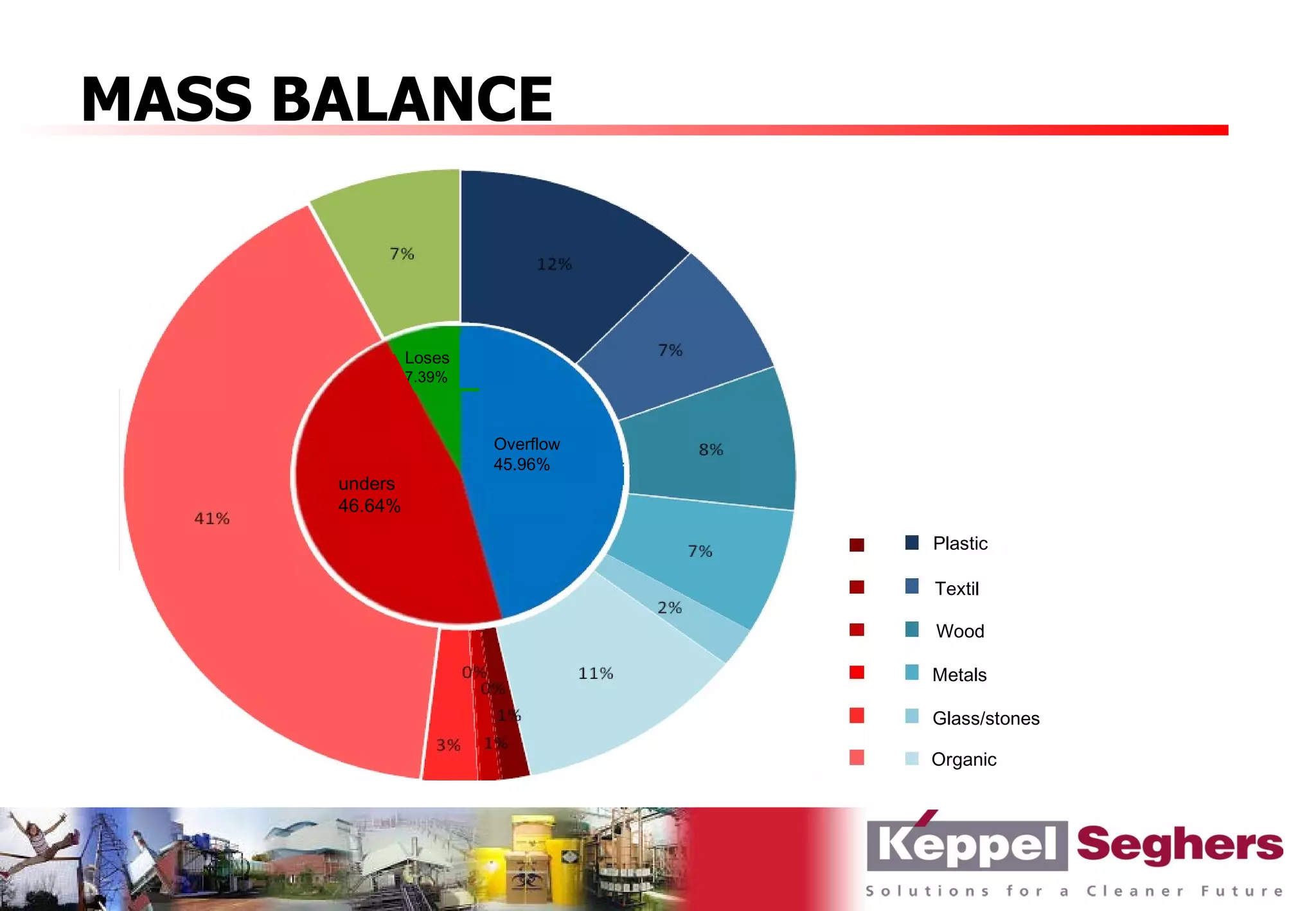

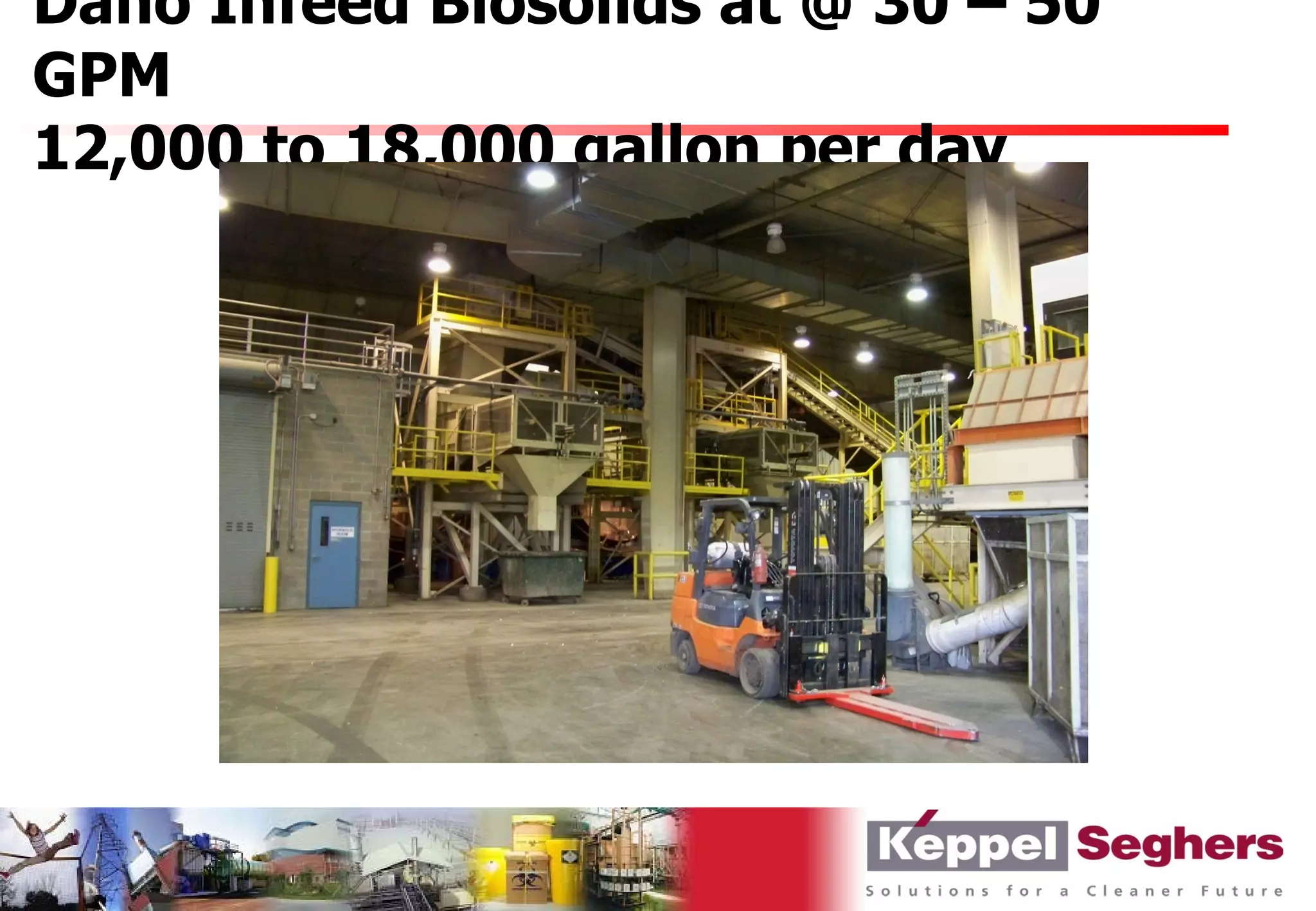

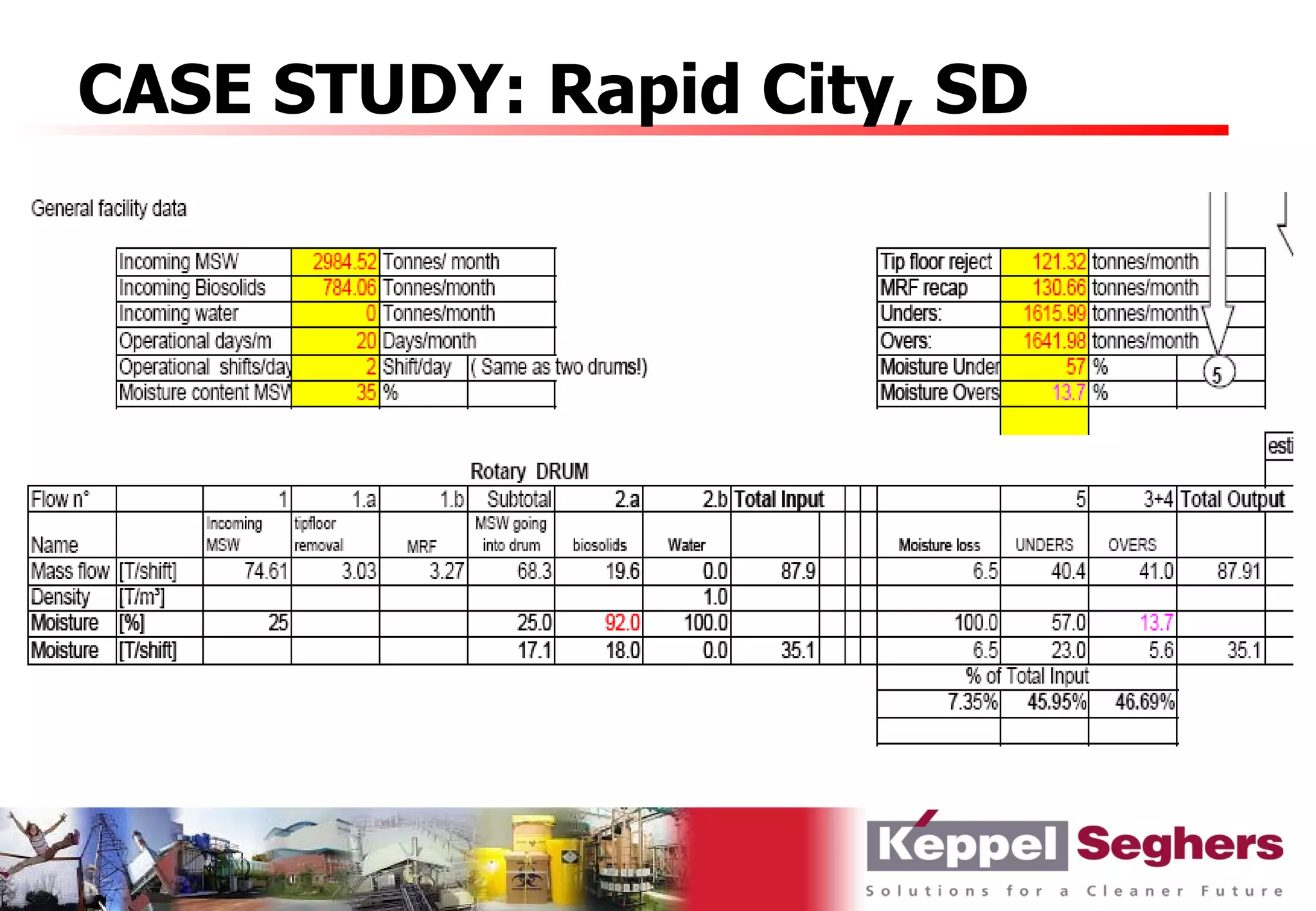

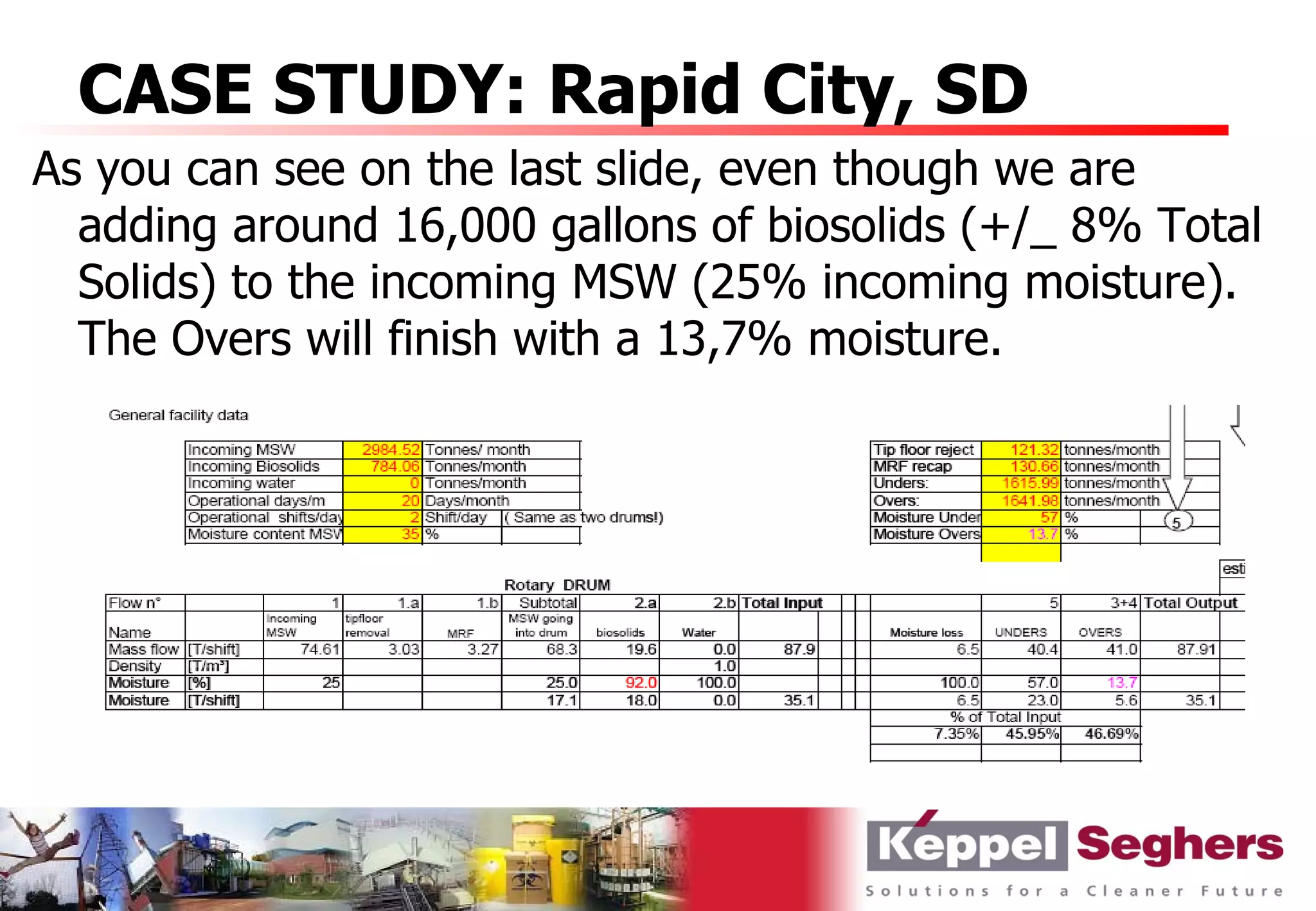

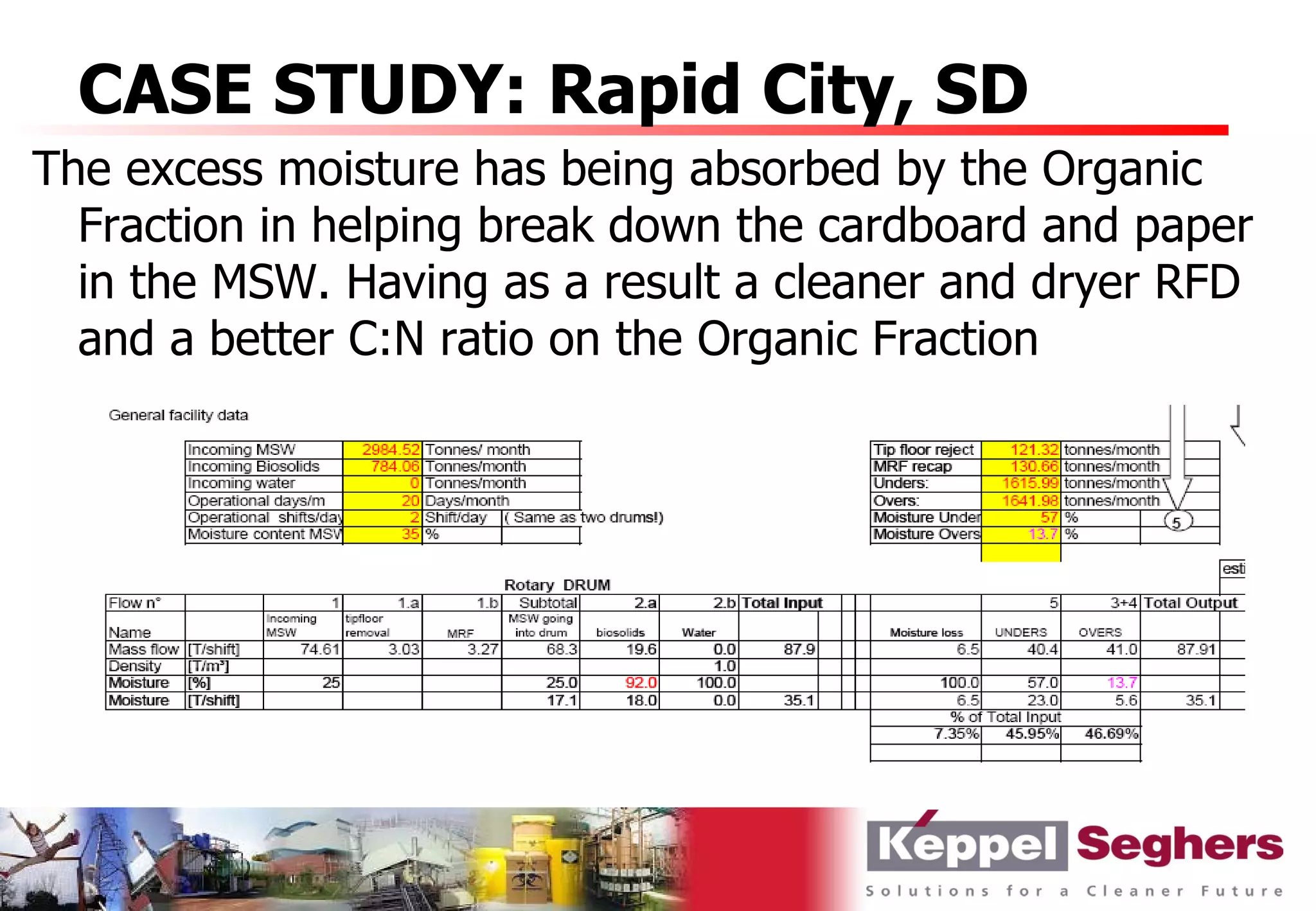

The Keppel Seghers DANO DRUM is a key element in waste pre-treatment. It is a horizontally mounted, rotating steel cylinder that shreds, mixes, conditions, and sorts waste into components for recycling, composting, or energy recovery. It allows maximum materials recovery while producing a fuel and pre-treating organic waste. A case study highlights how Rapid City, SD extended its landfill life by over 25 years using a DANO DRUM to process municipal solid waste and biosolids.