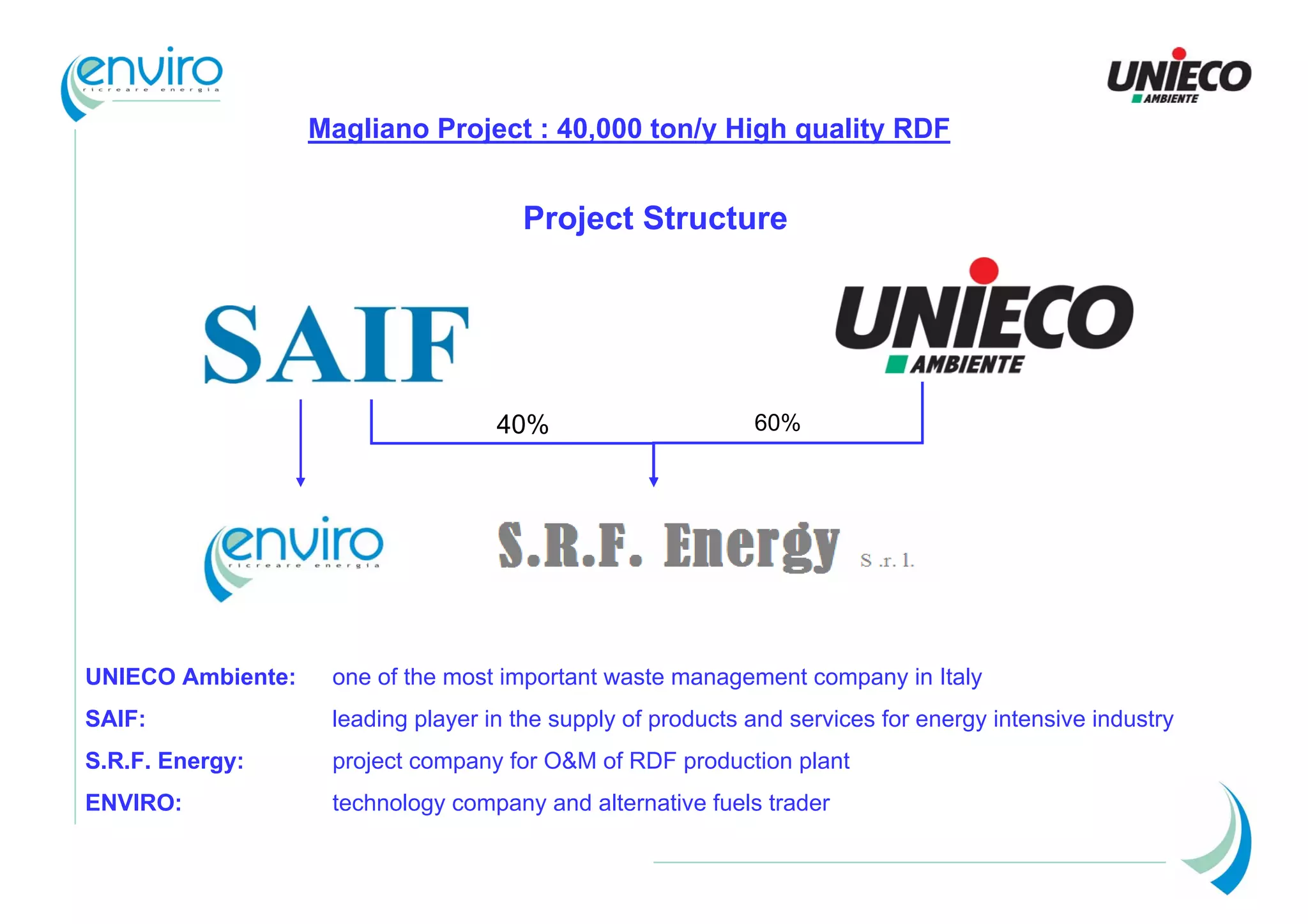

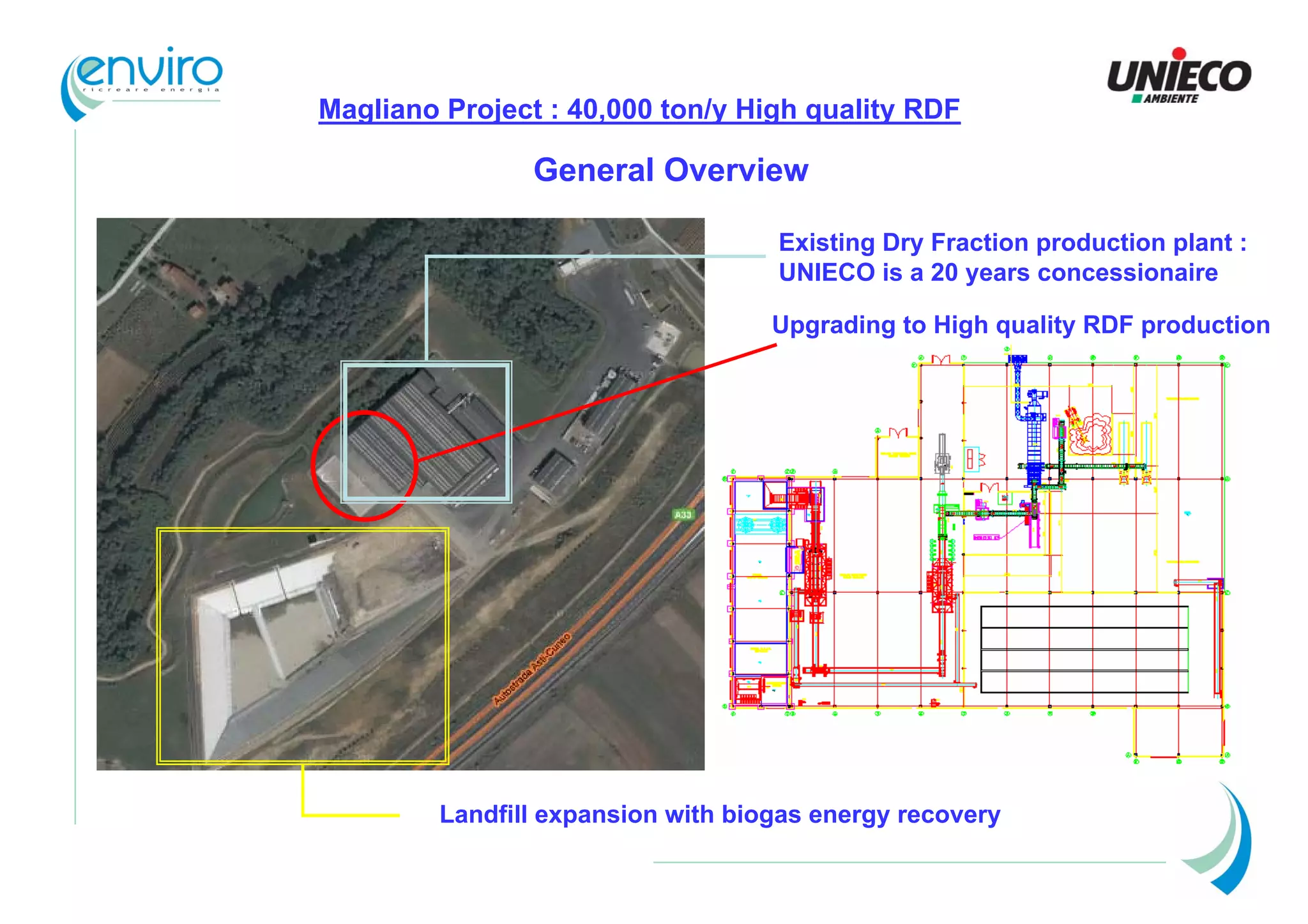

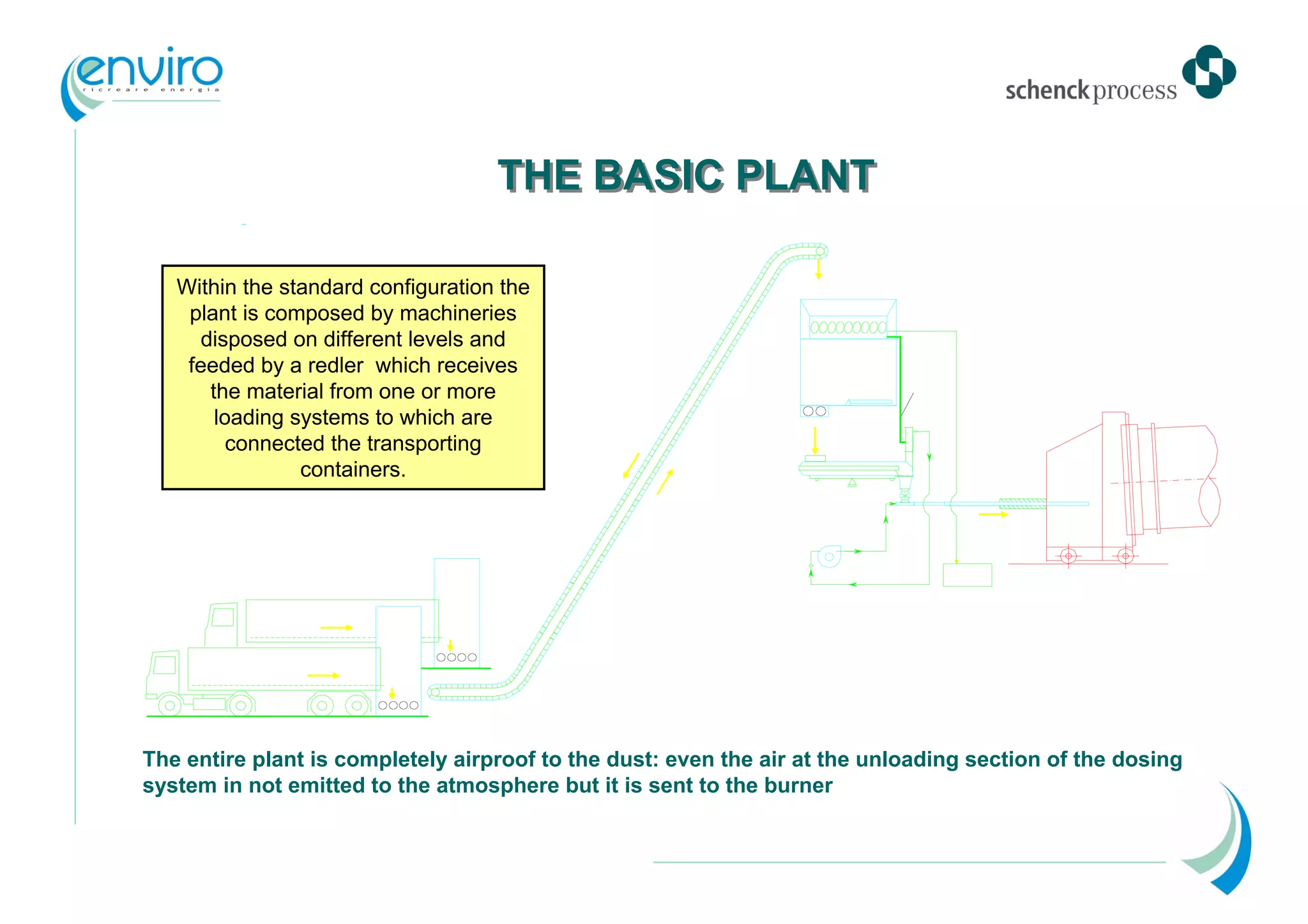

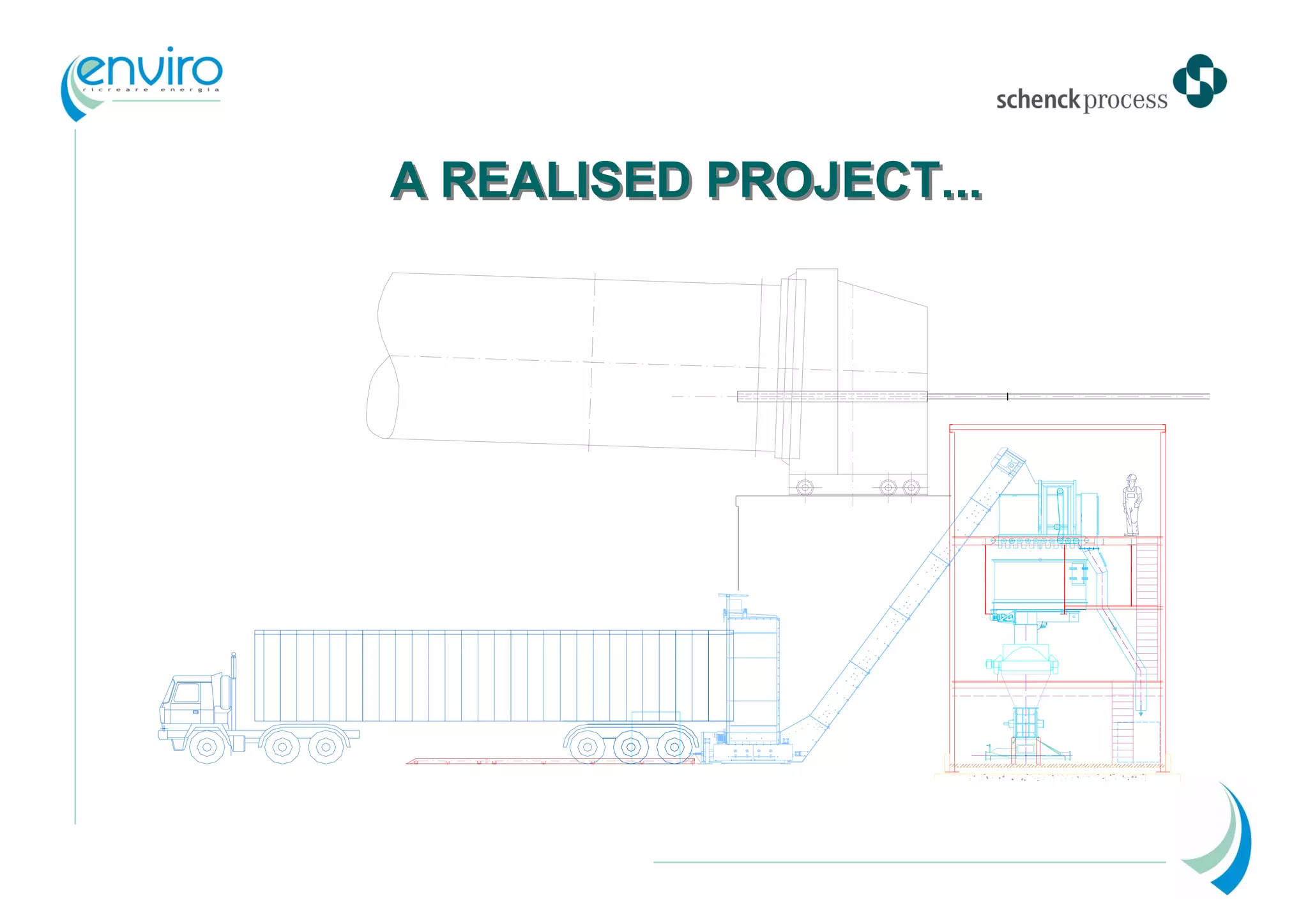

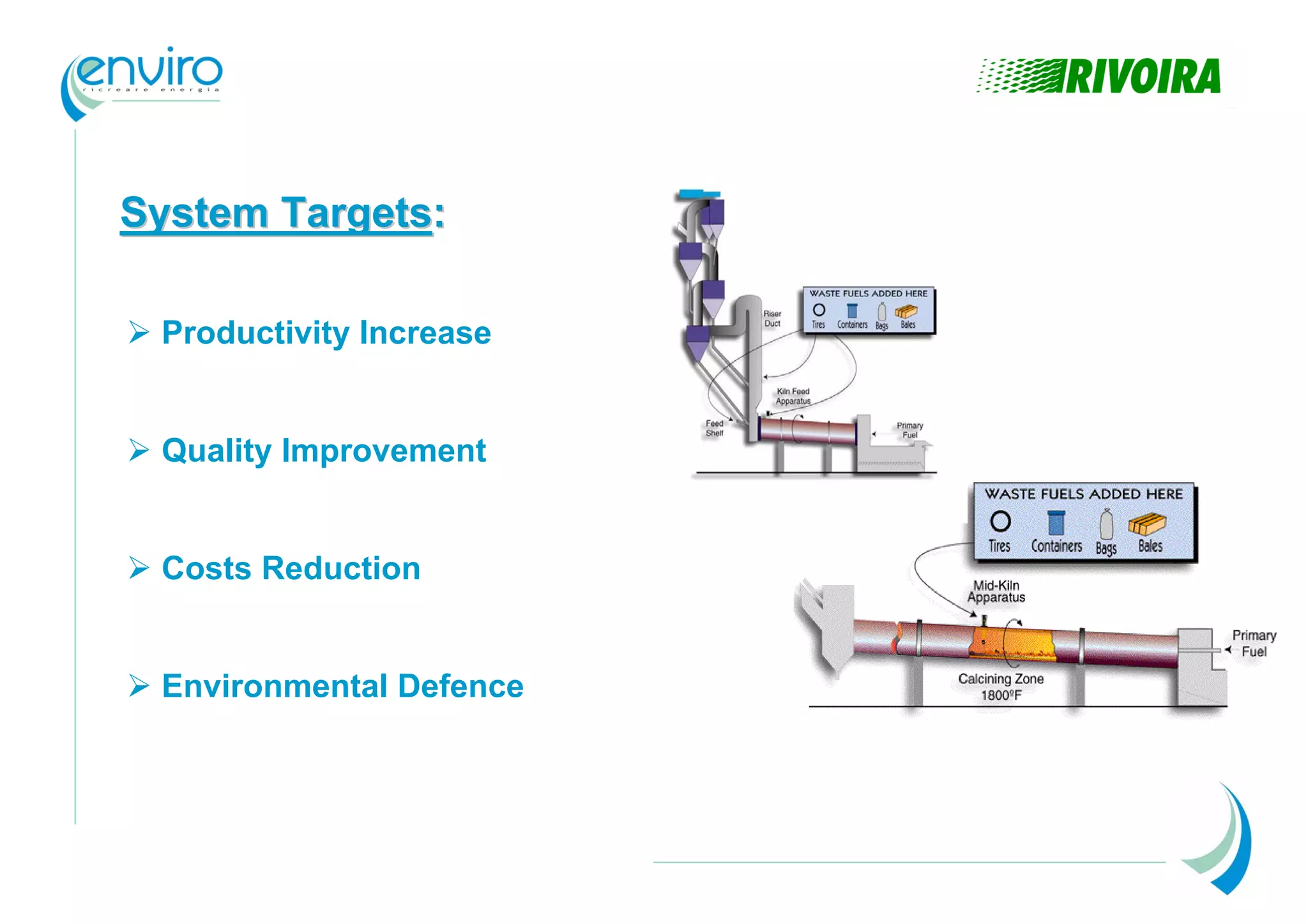

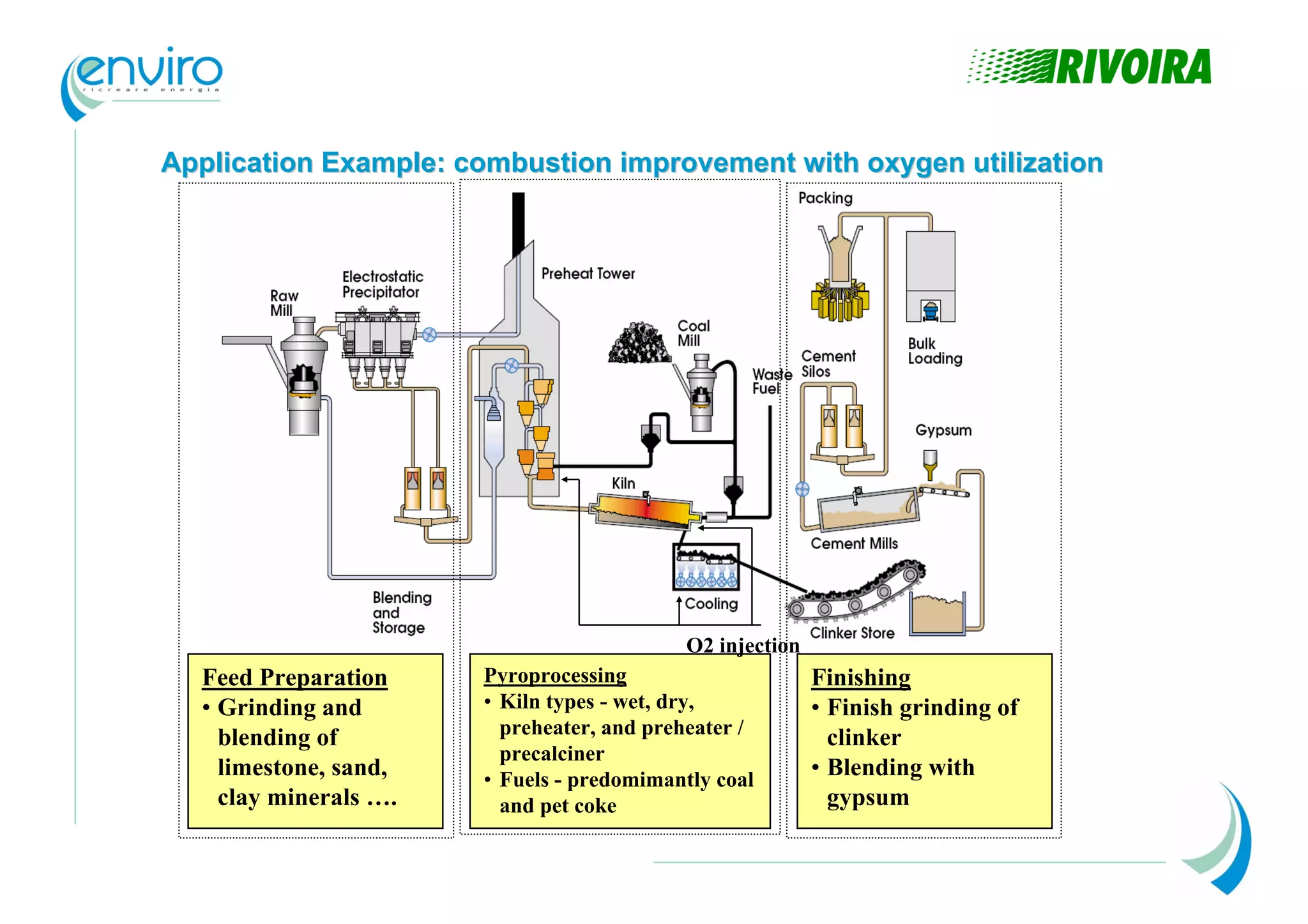

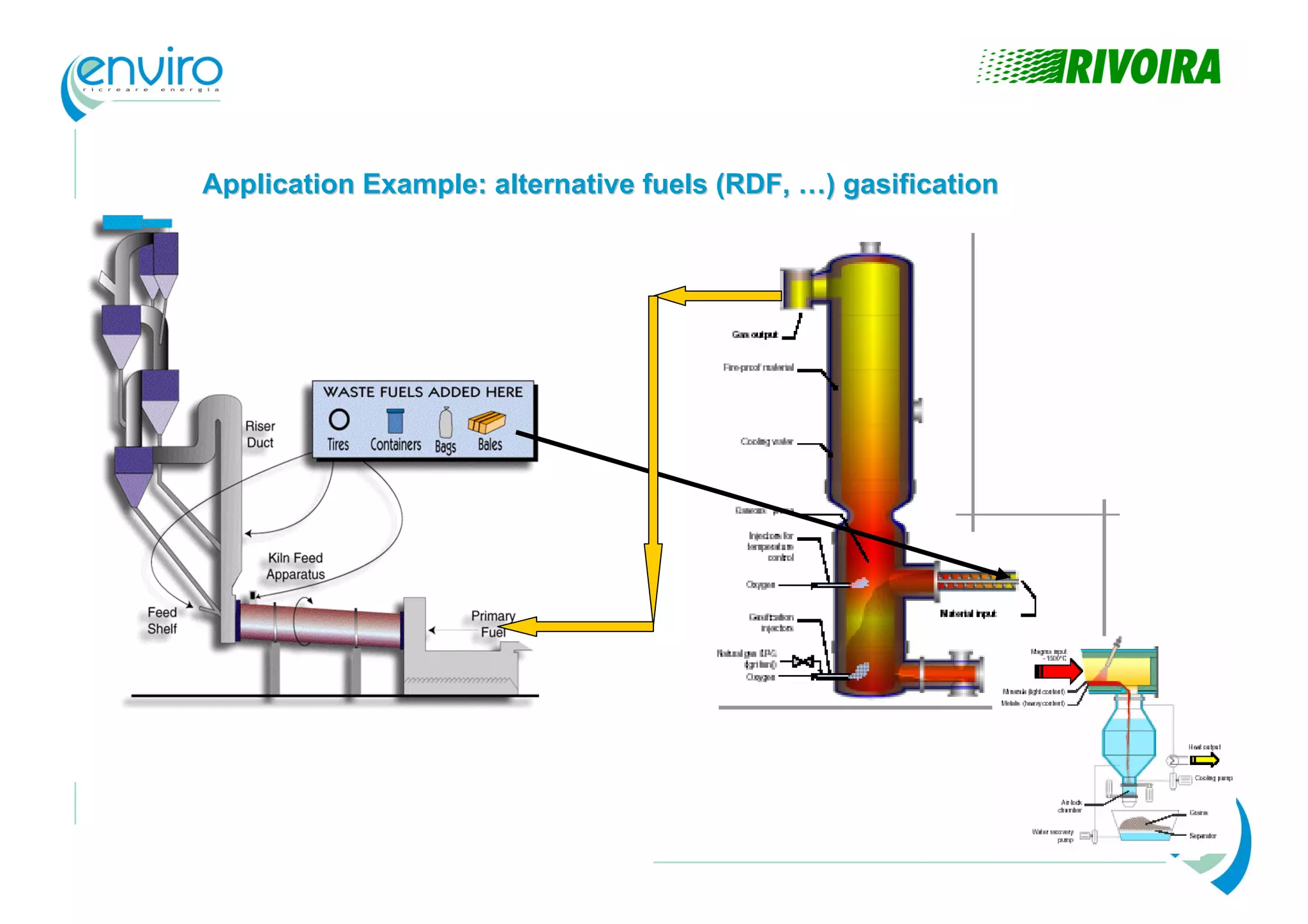

Enviro srl provides technical consultancy and alternative fuel supply services to support the growing alternative fuels market. It works with producers and end users to guarantee quality and consistent supply. Services include alternative fuel analysis, selection, authorization support, and high quality RDF production. Markets served include cement, lime, power plants, and dedicated alternative fuel plants. Products supplied include wood, biomass, waste materials, and customized mixtures. Enviro is part of the SAIF group and collaborates with partners on projects like a 40,000 tonne per year RDF plant. Dosing and combustion technologies are also offered to optimize alternative fuel use.