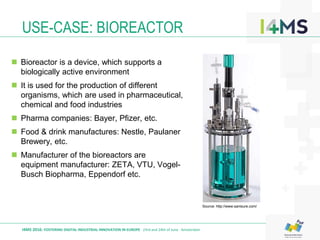

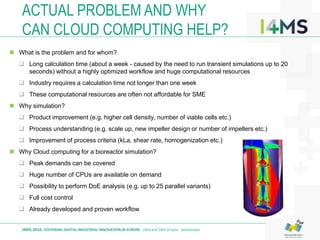

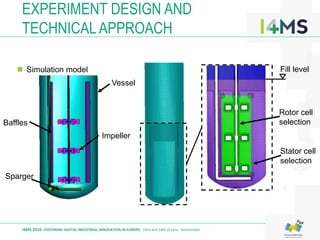

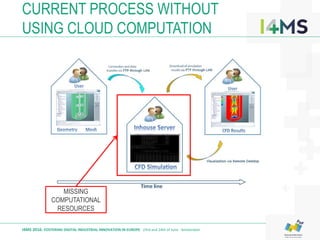

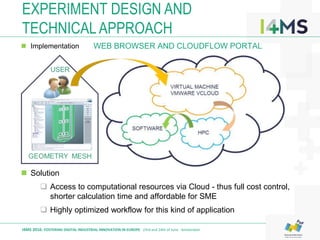

This document discusses a cloud-based simulation of fluid flow in a bioreactor. It notes that bioreactors are used in pharmaceutical, chemical, and food industries for producing organisms. Simulating bioreactors traditionally takes over a week due to computational requirements, which is too long for industry. Using cloud computing could reduce simulation time and make complex simulations affordable for small- and medium-sized enterprises. The document outlines a project involving three partners to develop a cloud-based workflow for bioreactor simulations and analyze the economic and time savings benefits compared to traditional high performance computing.

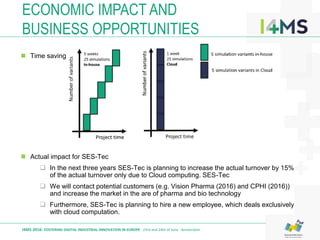

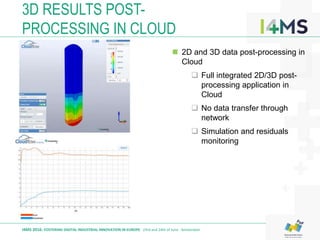

![ECONOMIC IMPACT AND

BUSINESS OPPORTUNITIES

I4MS 2016: FOSTERING DIGITAL INDUSTRIAL INNOVATION IN EUROPE · 23rd and 24th of June · Amsterdam

In house costs

45.000€ (12-16CPUs + License for

a year)

Utilization: about 80% per year

Cloud costs: 1,2 [€ / CPU h]

Real advantage of Cloud for an

end-user

Huge number of variants in short

calculation time, e.g. 25 variants in

one week (no investment costs).

Variant simulation (e.g. DoE) is

not direct comparable with in-

house calculation, due to very high

investment costs (e.g. 25*45.000€,

practically not possible for SMEs)

0

20000

40000

60000

80000

100000

120000

0 20 40 60 80 100

Costs[€]

Nr. of Variants

Cloud costs

In house costs

Cost saving](https://image.slidesharecdn.com/daliborjajceviccloudflowsestecv03final-160629135542/85/Dalibor-Jajcevic-SES-Tec-AT-CloudFlow-9-320.jpg)