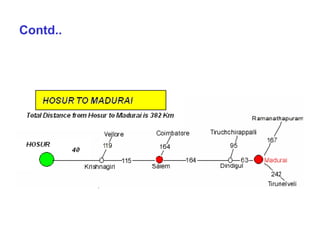

This document proposes an outbound distribution solution for Dabur's operations in India. Currently, Dabur uses 18 Central Fulfillment Agents (CFAs) and 150 stockists across India. The proposed solution involves establishing Regional Distribution Centers (RDCs) that would receive bulk shipments from Dabur plants and break them down by region. For example, an RDC proposed in Hosur, Tamil Nadu would service stockists in Tamil Nadu, Karnataka, and Kerala. The RDC would generate stockist-specific orders and shipments, which would be invoiced at billing points located near major stockists. This would consolidate inventory and transactions while allowing for next-day delivery to most stockists. Establ