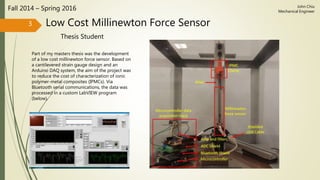

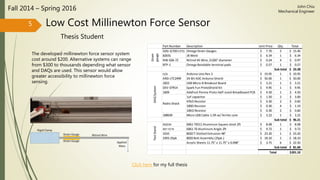

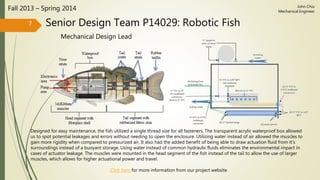

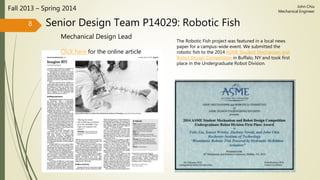

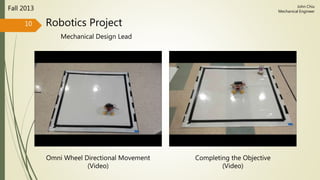

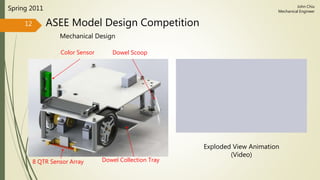

John Chiu is a mechanical engineer seeking a position. His portfolio summarizes several projects from his education experience including developing a low-cost force sensor for his master's thesis. As an undergraduate, he led the design of a robotic fish and worked on a Baja car competition. He has experience in mechanical design, CAD modeling, robotics, and sensor integration.