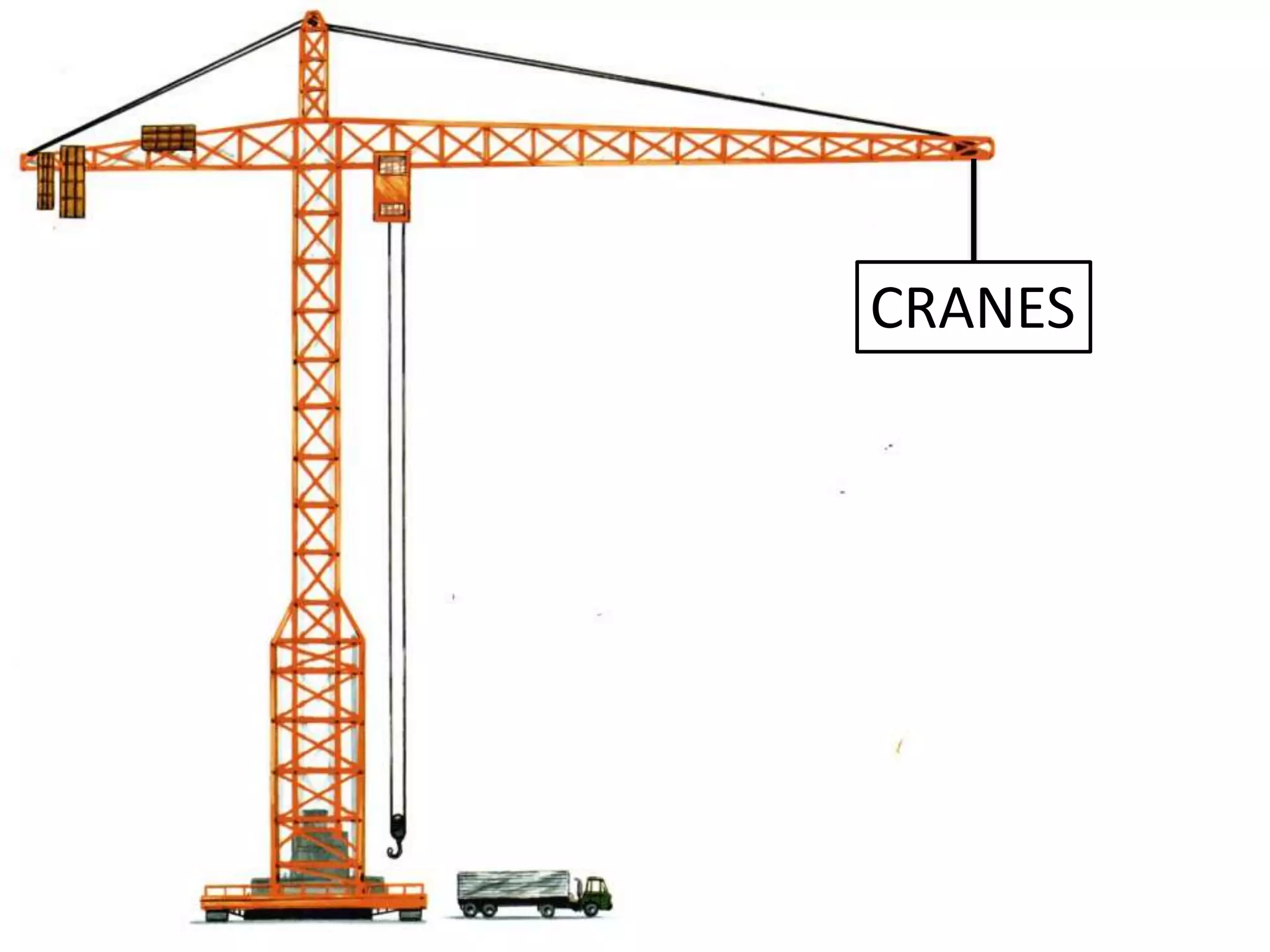

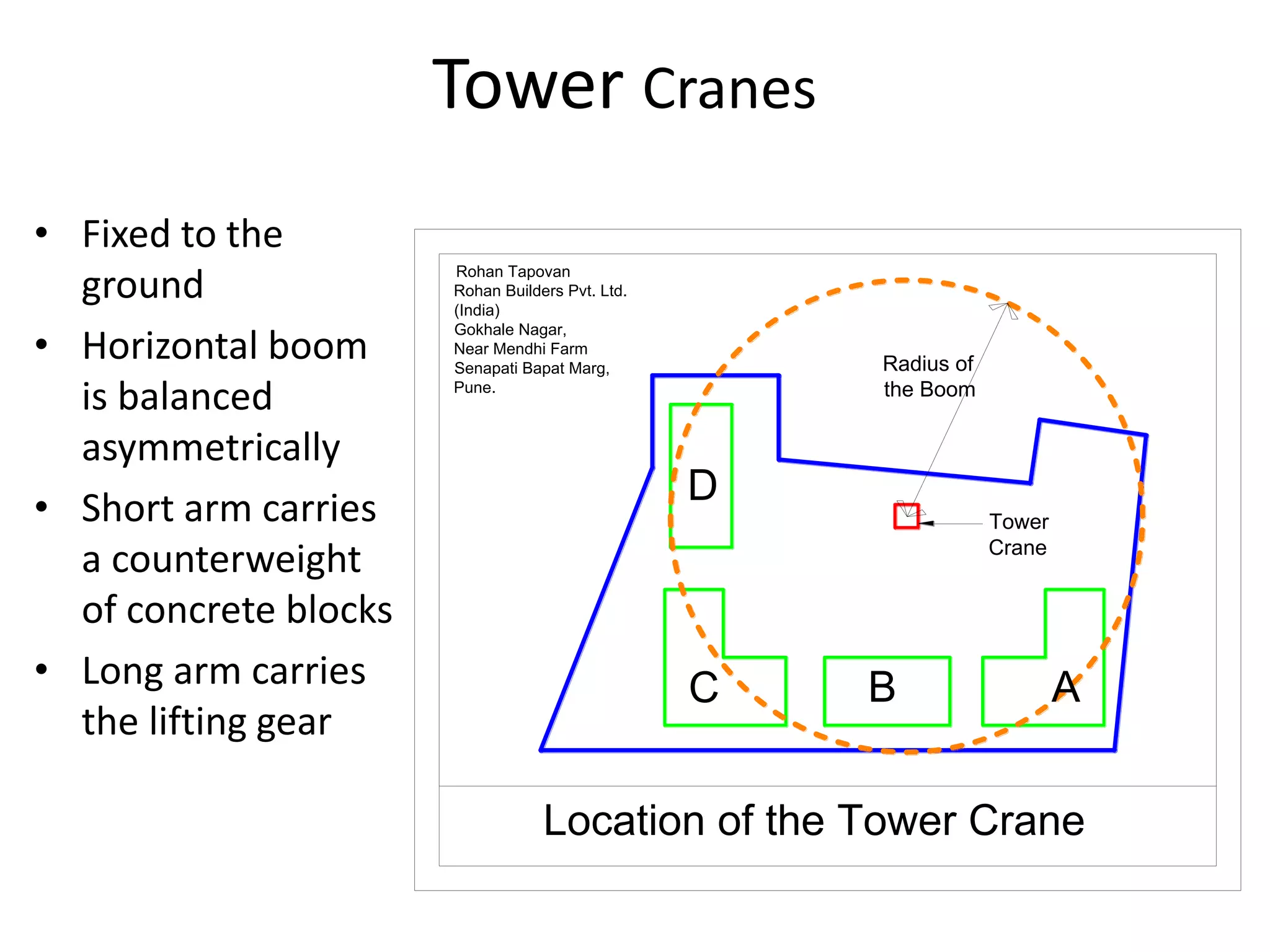

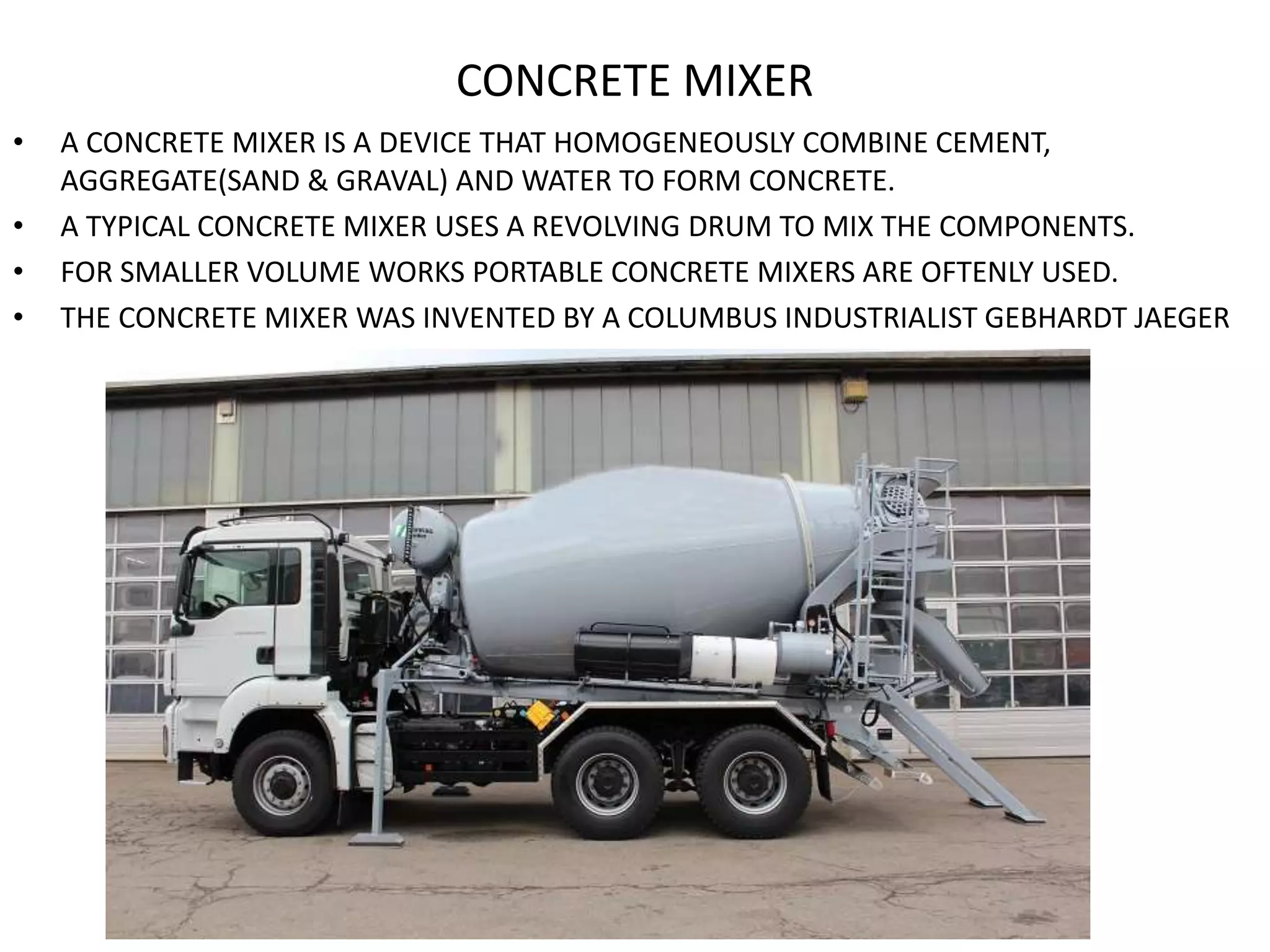

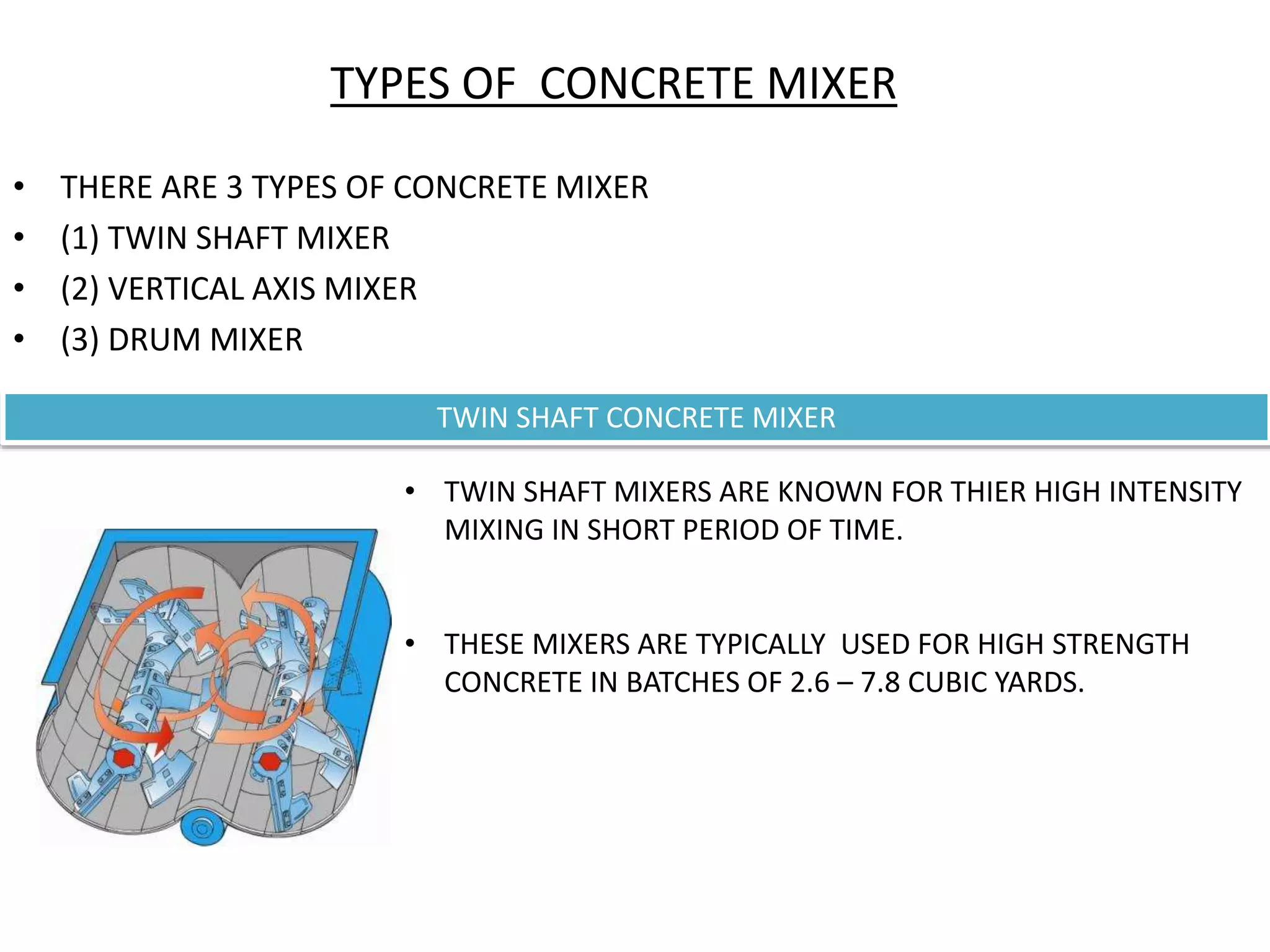

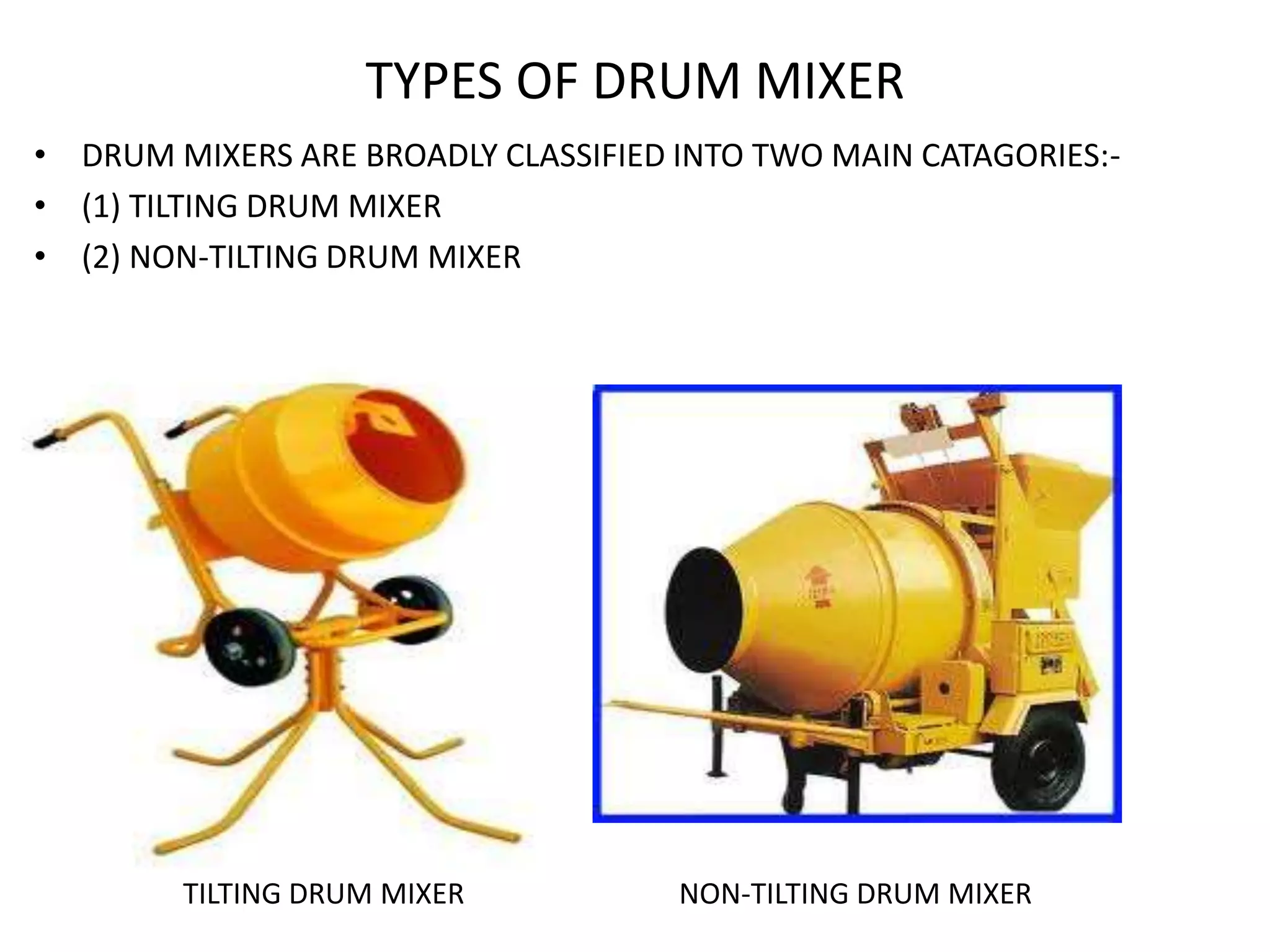

Cranes are lifting machines that use pulleys and cables to lift heavy loads. Ancient Greeks invented early construction cranes, while modern cranes can be huge tower cranes with reaches of 800 meters used for infrastructure projects. There are different types of cranes like mobile cranes, tower cranes, overhead cranes and more. Mobile cranes can transport to sites and lift various loads, operating booms from ends with suspended hooks. Tower cranes are fixed to the ground with a horizontal boom balanced asymmetrically by a short counterweight arm and long lifting gear arm. Concrete mixers homogenously mix cement, aggregates and water to form concrete using revolving drums. There are twin shaft, vertical axis and drum mixers