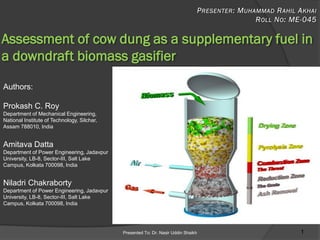

1. The document presents a model for assessing cow dung as a supplementary fuel in a downdraft biomass gasifier. The model divides the gasification process into two zones: (1) an oxidation zone modeled using chemical equilibrium and (2) a reduction zone modeled using chemical kinetics.

2. The model considers gasification of mixtures of cow dung and sawdust. Results are compared to experimental data from previous studies. Key outputs include producer gas composition, heating value, production rate, and a gasifier conversion efficiency.

3. A cost analysis compares the fuel costs of sawdust and cow dung mixtures based on the usable energy produced by combustion of the resulting producer gas.

![2. LITERATURE REVIEW

Presented To: Dr. Nasir Uddin Shaikh 6

2.1 Previously Researched work

Many researchers adopted the kinetic modelling in the reduction zone of the gasifiers

after considering chemical equilibrium of species in the pyrolysis/oxidation zone

Giltrap et al. [20] considered the chemical kinetics of four important reactions in the

redction zone for a good prediction of the producer gas composition and temperature.

The model output was found to be sensitive at the initial temperature and composition

at the top of the reduction zone.

Giltrap et al. further took into account a constant char reactivity factor, to take care of

the active reaction sites in the reduction zone

Sharma [22] considered two distinct zones in the gasifier: pyro-oxidation zone and char

reduction zone. The gaseous products of the pyro-oxidation zone are considered to be

in equilibrium, while the char is considered as a non-equilibrium product from this zone.

Formation of methane is neglected in the pyro-oxidation zone. Kinetic controlled

reduction by char is considered in the reduction zone with the same equations as

suggested by Giltrap et al., but with linearly varying char reactivity factor.](https://image.slidesharecdn.com/0c33ab5c-aa0f-4bbc-9719-bca40c96f156-150909060248-lva1-app6891/85/COW-DUNG-6-320.jpg)

![ The on-site cost of sawdust may be taken as Rs. 1000/- per tonne [27], while that of

cow dung may be taken as Rs. 250/- per tonne.

We cannot compare the fuel cost on the basis of unit quantity of gas produced as the

heating value of the producer gas also varies with the change in the constituent of the

blend.

We have rather compared the fuel cost based on unit amount of energy that can be

obtained through the combustion of the producer gas.

The results show that the cost is the minimum with a fuel blend containing 40–50% of

the cow dung by mass.

Presented To: Dr. Nasir Uddin Shaikh 18](https://image.slidesharecdn.com/0c33ab5c-aa0f-4bbc-9719-bca40c96f156-150909060248-lva1-app6891/85/COW-DUNG-18-320.jpg)