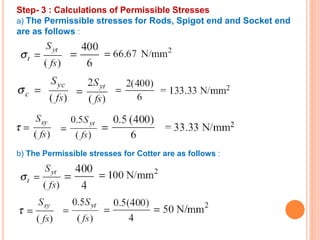

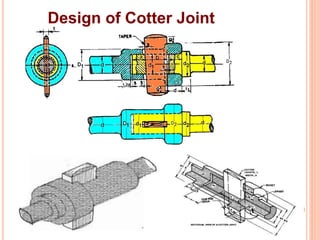

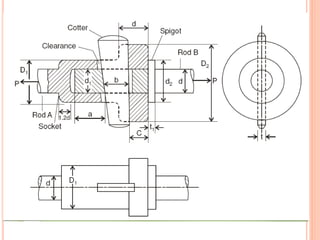

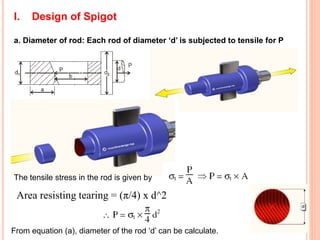

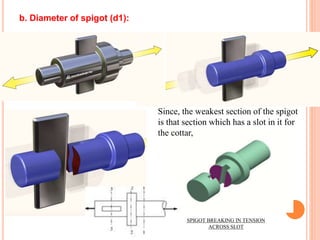

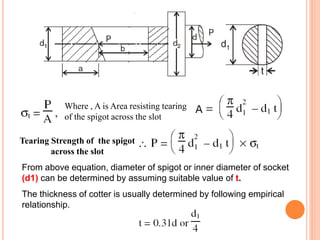

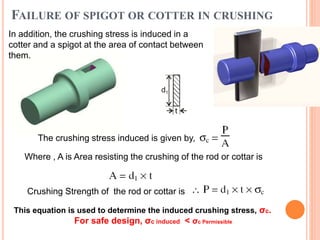

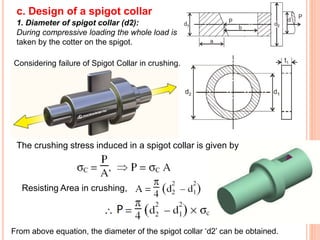

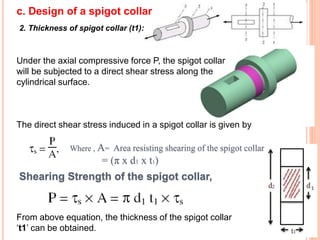

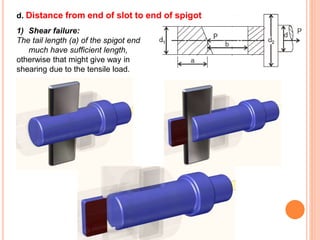

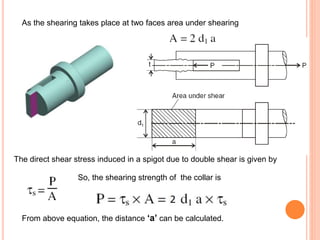

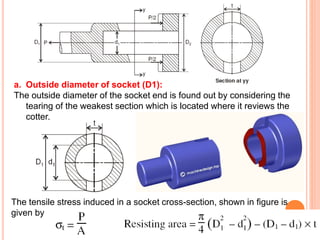

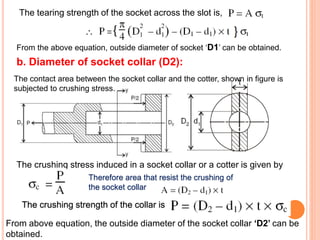

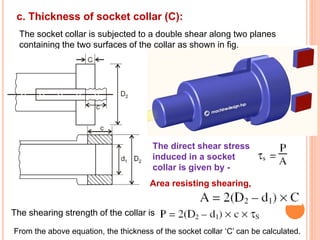

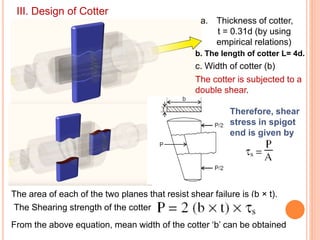

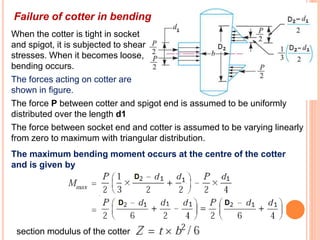

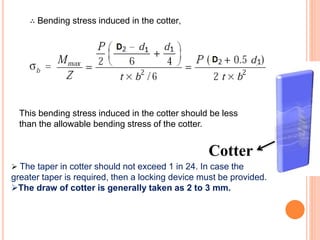

The document provides the step-by-step process for designing a cotter joint to connect two steel rods subjected to an axial tensile force. It involves selecting the material (plain carbon steel), selecting a factor of safety of 6 for the rods and ends and 4 for the cotter, calculating permissible stresses, and designing the spigot, socket, and cotter dimensions based on equations considering failure by tension, crushing, shear, and bending. The key dimensions designed and specified are the diameters of the rod, spigot, socket ends and collars, thicknesses of the spigot and socket collars, length and width of the cotter.