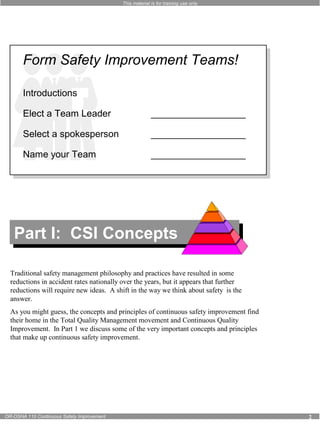

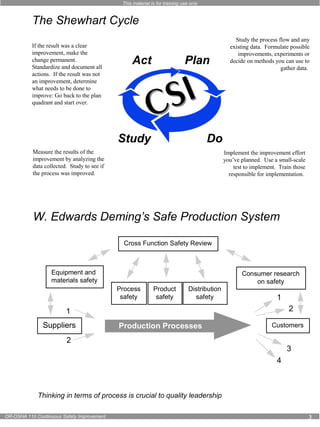

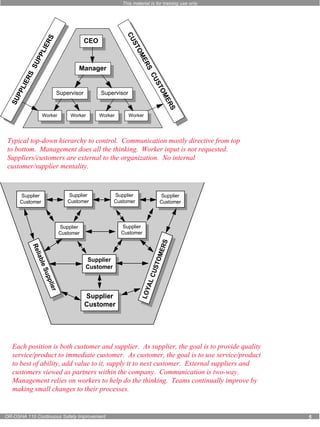

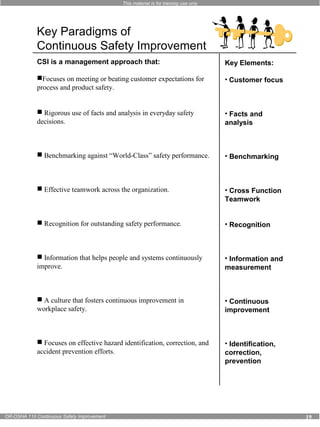

This document discusses the concepts and principles of Continuous Safety Improvement (CSI) and how they relate to Total Quality Management. It provides an overview of two workshop goals: 1) becoming familiar with the origins and contributions of the Total Quality Management movement and W. Edwards Deming, and 2) applying Deming's 14 Points to workplace safety. Several of Deming's 14 Points are then examined in more detail and how they can guide a proactive, systems-based approach to safety management focusing on continuous improvement.