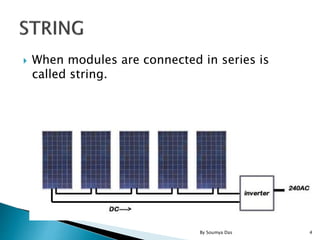

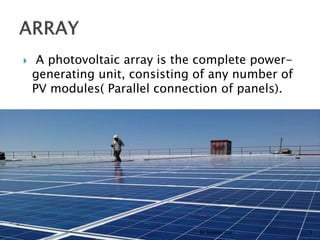

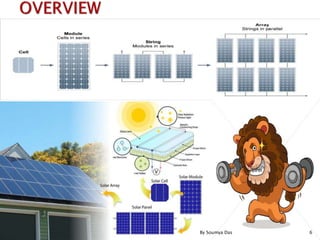

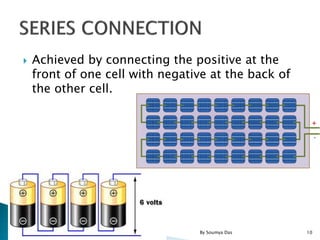

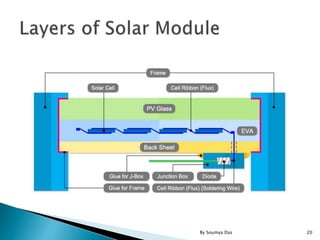

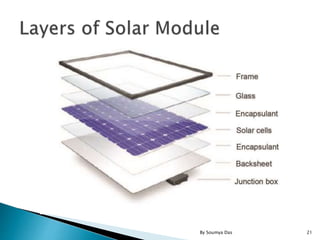

The document explains the components and functioning of photovoltaic (PV) modules, which convert solar radiation into electricity. Key parts discussed include solar cells, glass, encapsulant materials like EVA, backsheet, interconnect ribbons, junction boxes, and frames, each serving specific protective and electrical roles. It emphasizes the connectivity and arrangement of cells in series and parallel to optimize power generation.