1. Concrete is the most widely used man-made material on Earth and is composed of cement, fine and coarse aggregates, and water.

2. When water reacts with cement through a process called hydration, it causes the cement to harden and bind the other components together to form concrete.

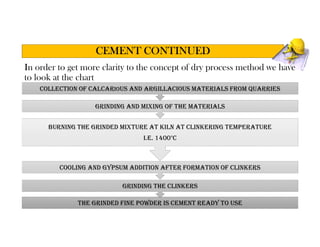

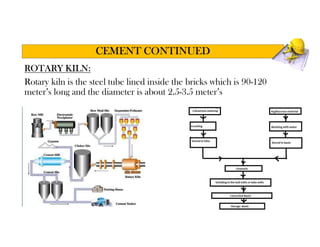

3. Cement is produced by heating limestone and clay at high temperatures in a kiln to form clinker, which is then ground with gypsum into a powder to create cement.