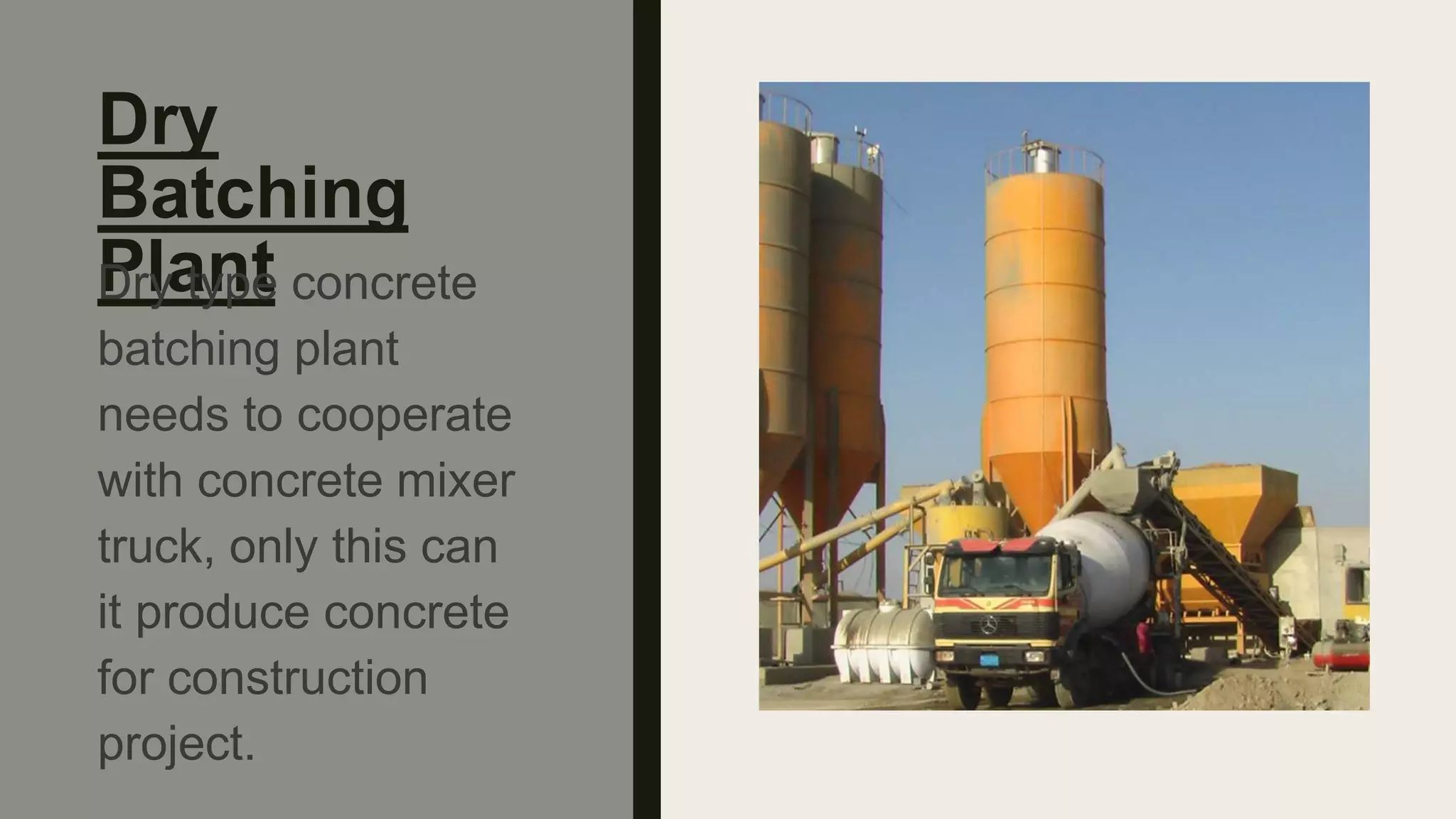

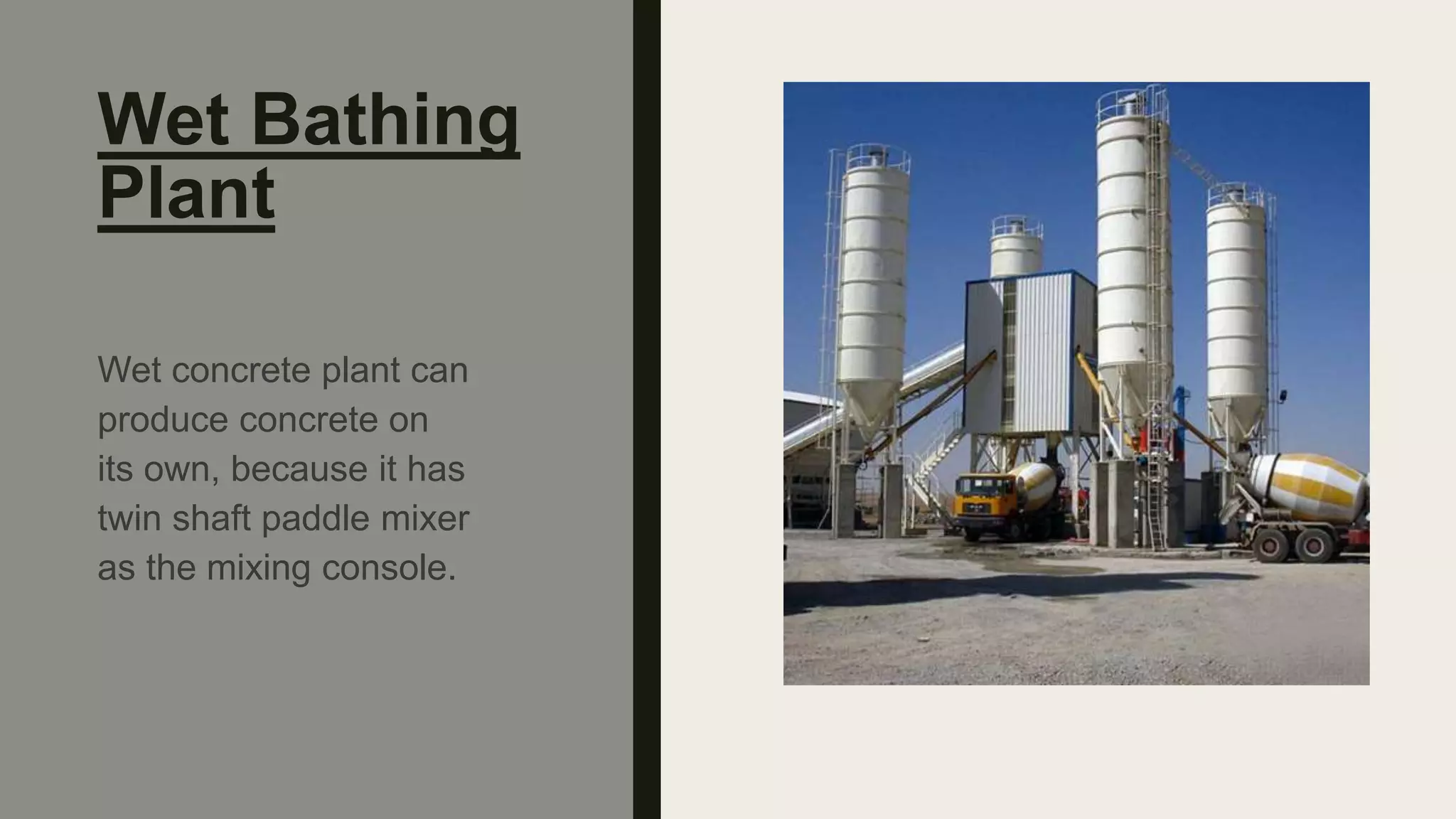

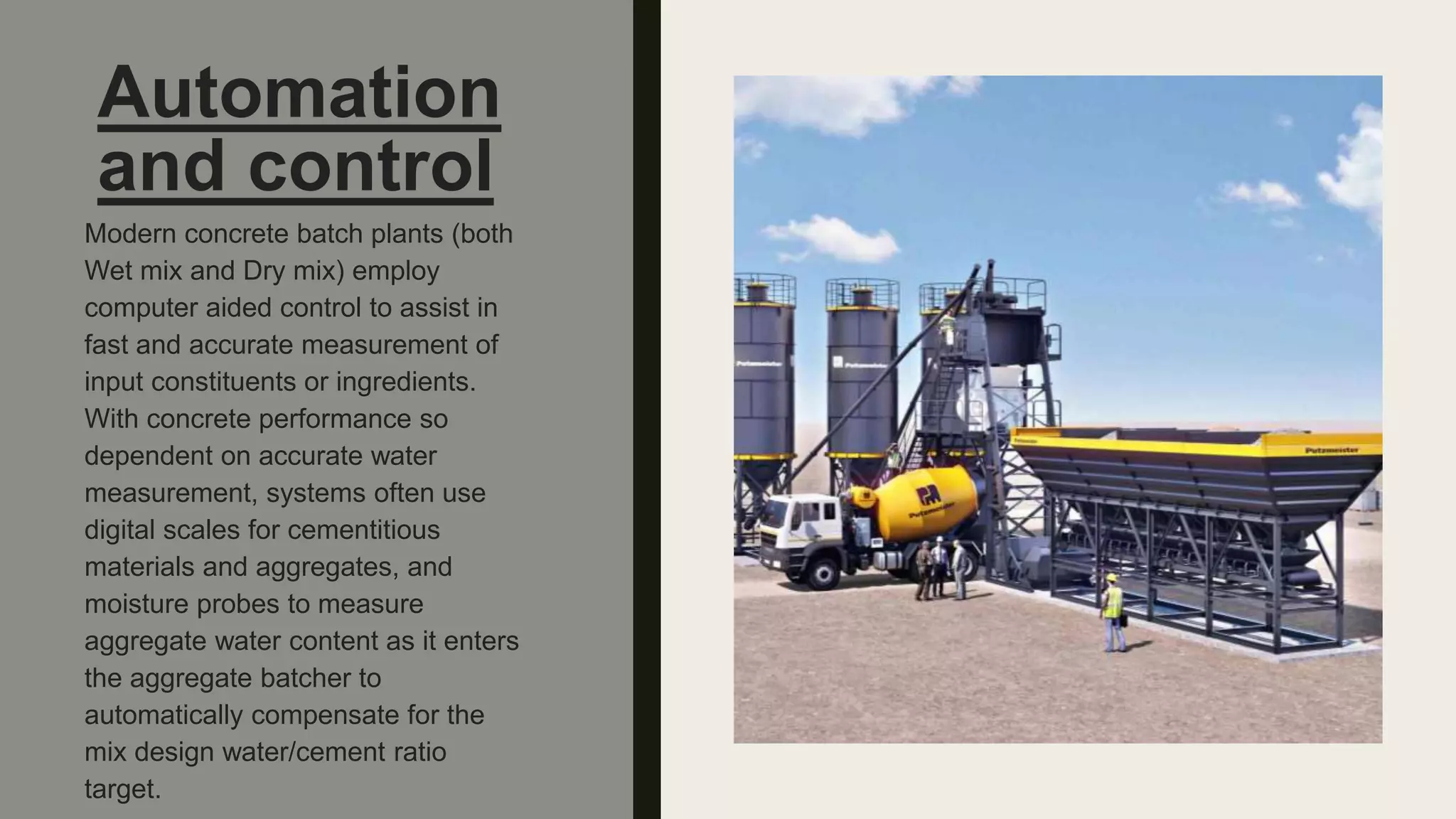

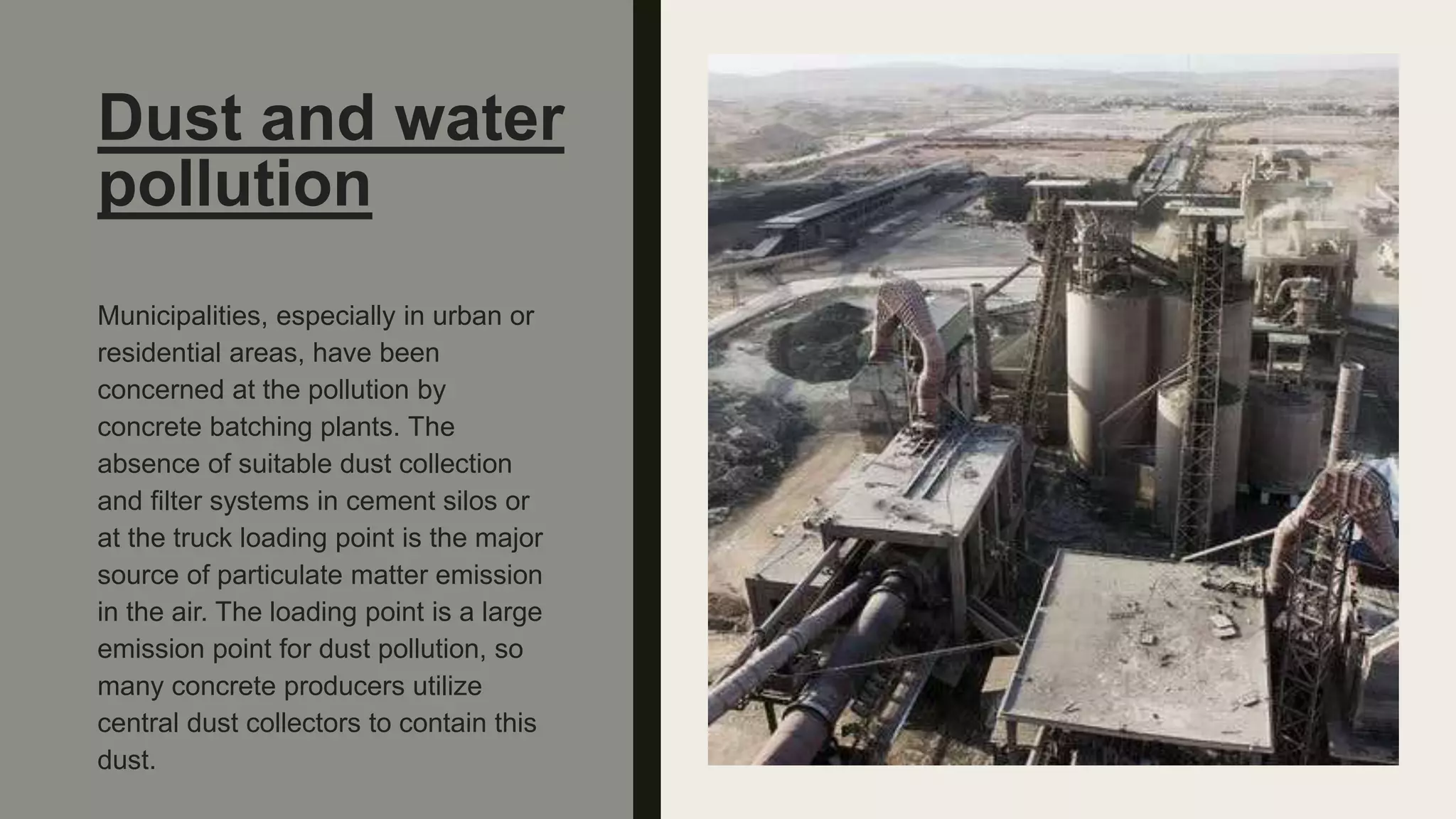

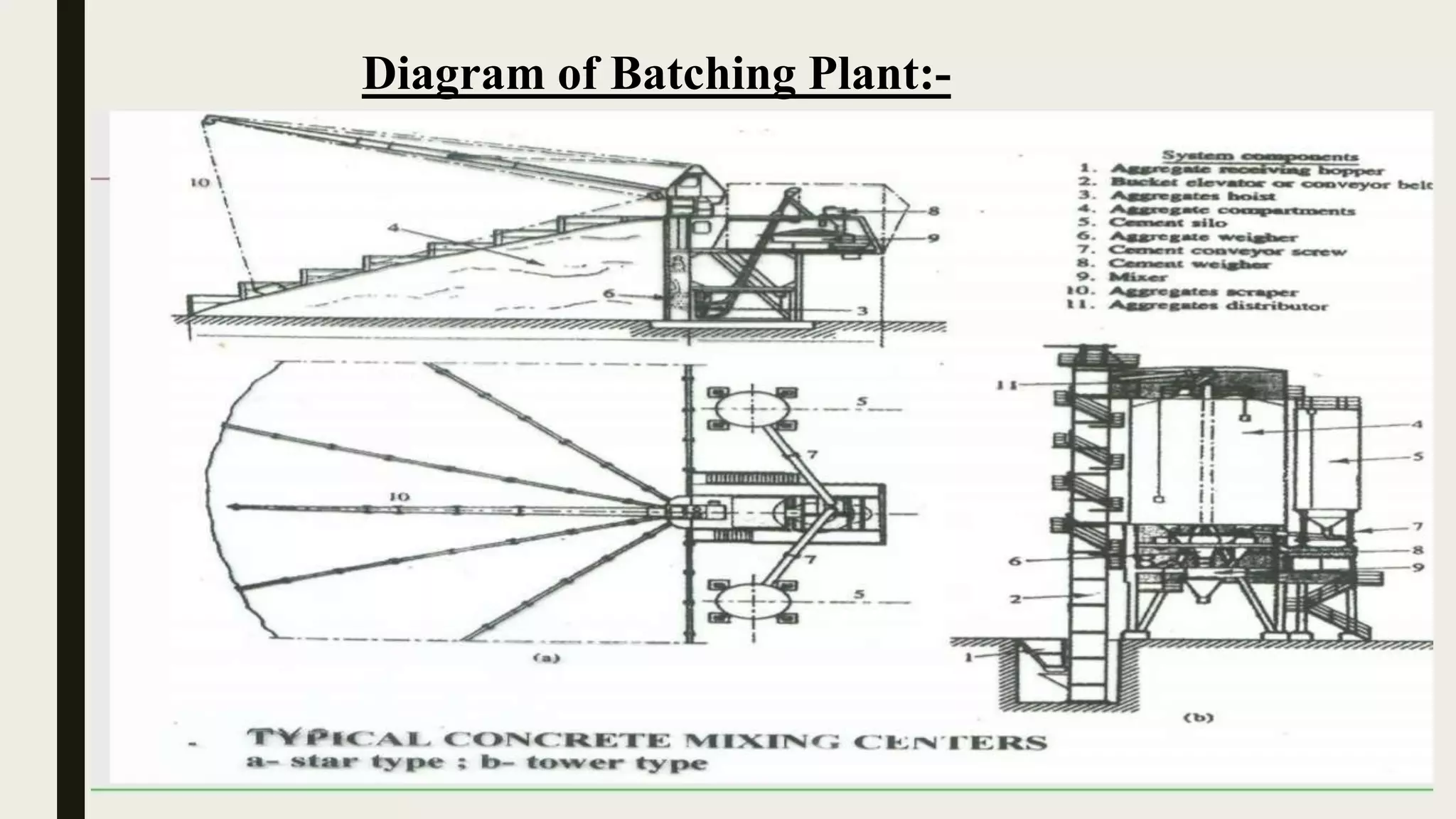

A batching plant combines ingredients like water, cement, aggregates, and admixtures to produce concrete. There are two main types: dry batching plants, which need to be used with concrete mixer trucks, and wet batching plants, which can mix concrete on their own. The batching process involves weighing the ingredients on a mass basis for accuracy. Batching plants can be portable, stationary, or semi-portable. Modern plants use computer automation to measure ingredients accurately. Dust and water pollution are concerns that require mitigation measures like dust collection systems. Key components include bins, conveyors, scales, silos, and dispensing systems.