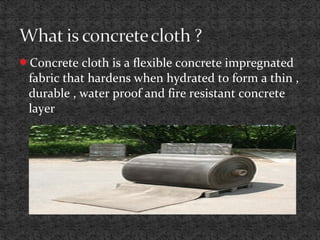

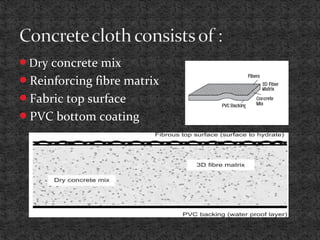

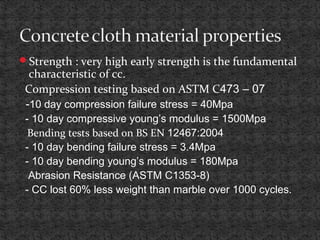

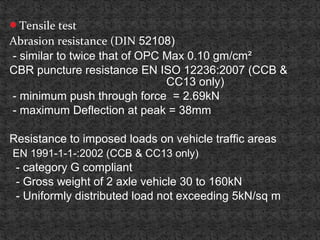

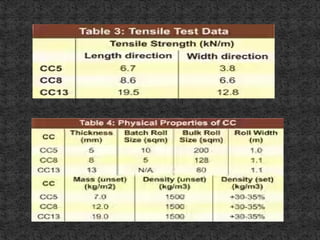

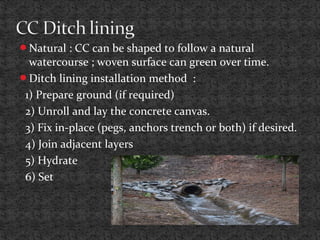

This document discusses concrete cloth, a flexible concrete-impregnated fabric that hardens when hydrated. It was developed by a British engineering company to provide a rapidly deployable emergency shelter. When hydrated, concrete cloth forms a thin, durable, waterproof and fire-resistant concrete layer. It has a variety of uses in construction and infrastructure projects due to its strength, flexibility, and ease of installation. Concrete cloth can be cut, joined, painted, and installed using common tools and techniques.