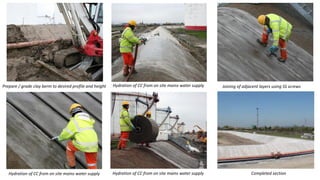

Concrete Cloth (CC) is a flexible concrete material used to armor and protect earthen berms at oil refineries. CC hardens upon hydration to form a durable fiber-reinforced concrete layer preventing erosion from weathering. It can be rapidly installed by a small crew at over 3,000 square feet per day. CC conforms well to protrusions and corners, and allows installation in wet conditions, reducing delays from poor weather. It provides effective protection for sensitive infrastructure and prevents damage from animals or fires.