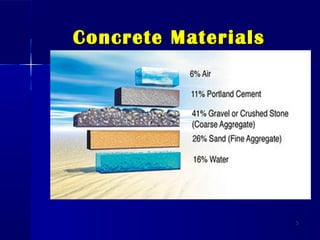

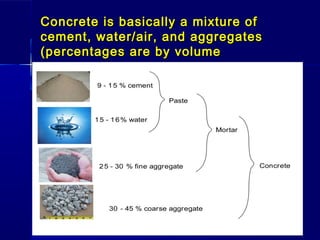

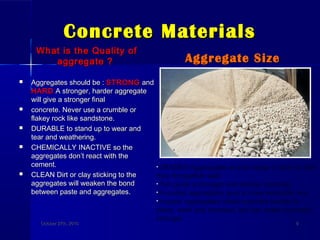

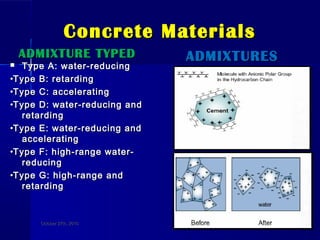

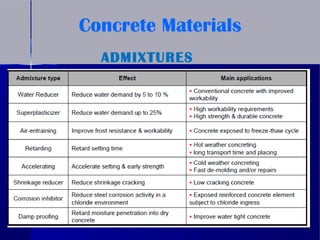

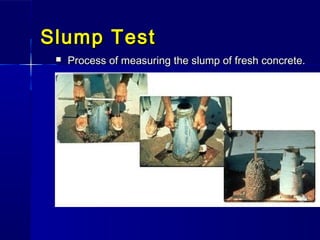

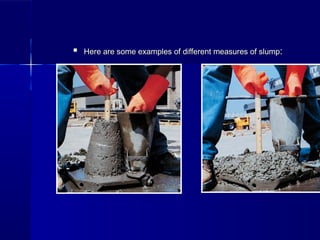

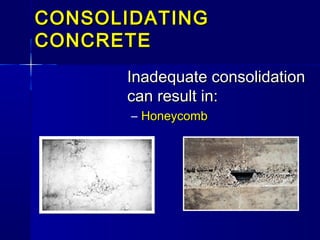

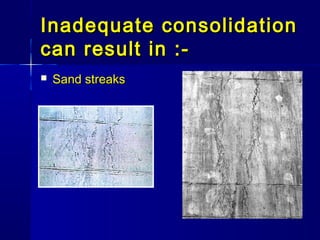

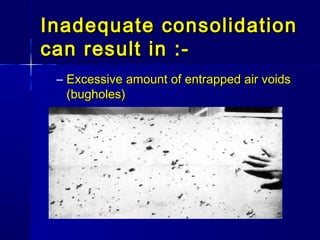

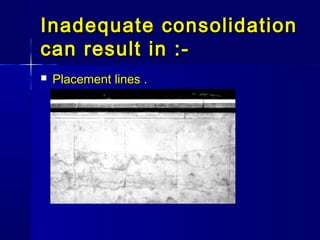

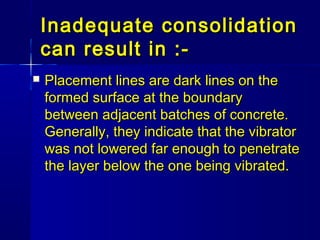

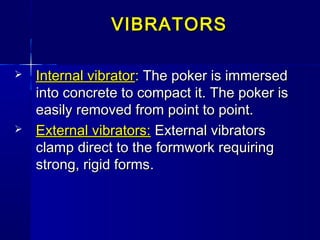

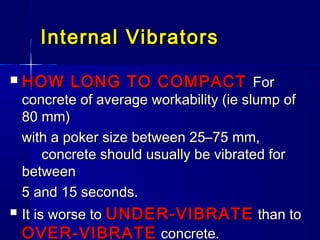

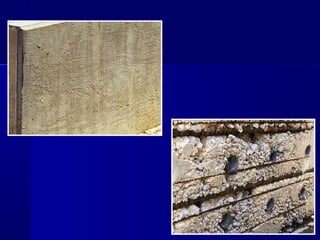

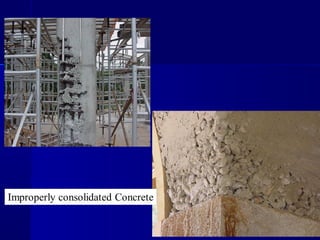

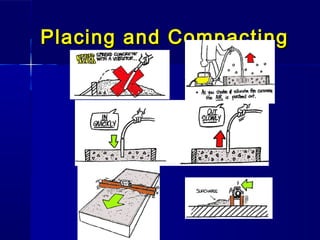

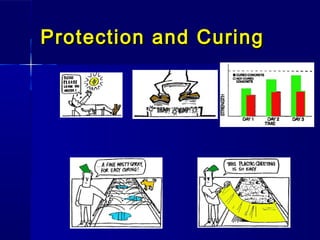

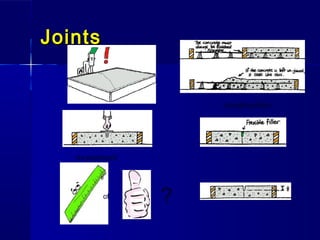

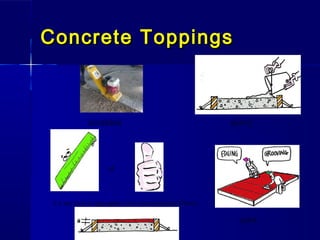

This document provides an overview of concrete basics including materials, properties, mixing, placing, and curing. It discusses the components of concrete including cement, water, aggregates, and admixtures. It describes the three states of concrete: plastic, setting, and hardening. It outlines best practices for mixing, placing, consolidating, and curing concrete to achieve optimum strength and durability. Inadequate consolidation can result in defects like honeycombing, sand streaks, or cold joints between batches.