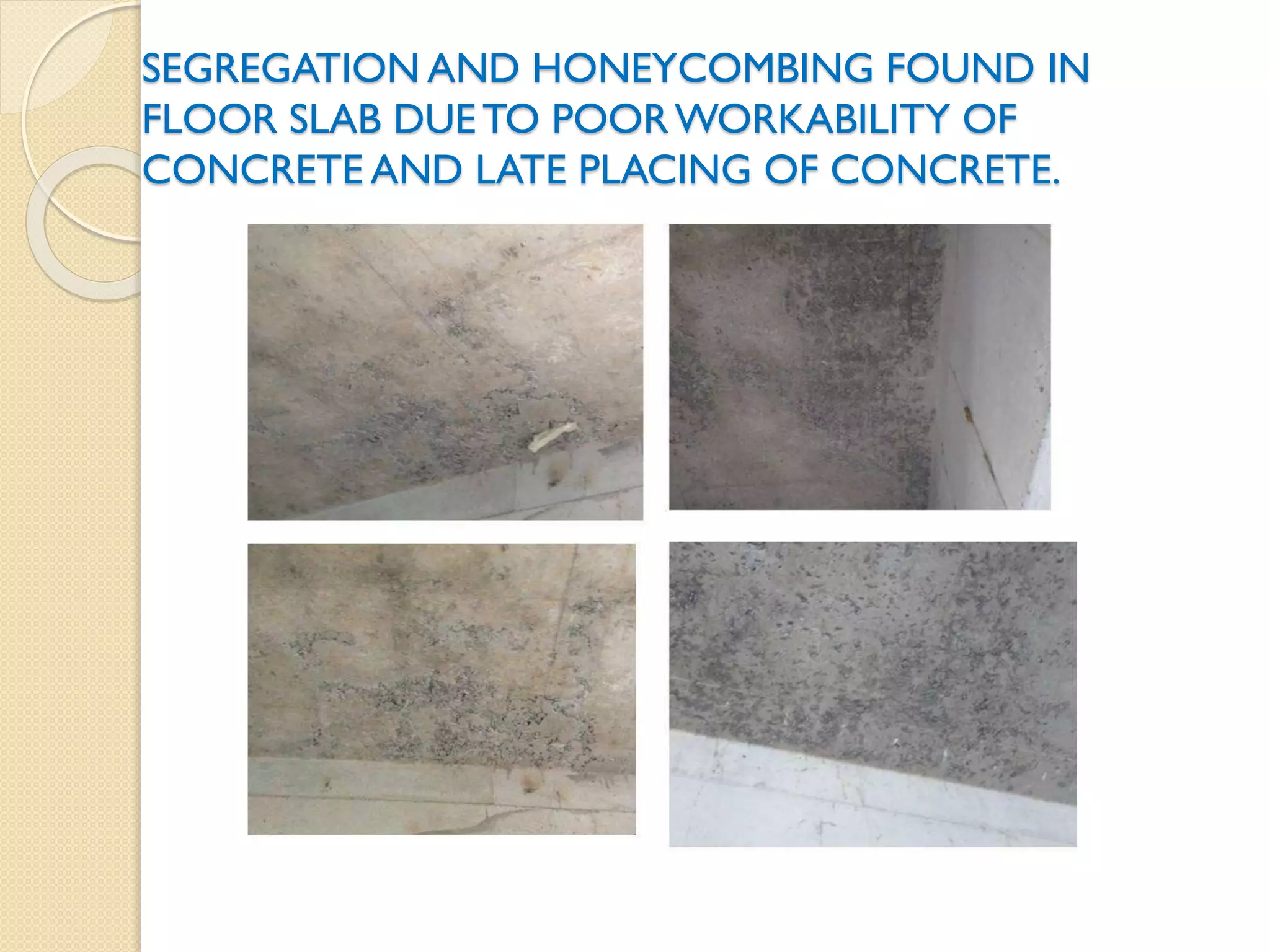

Segregation and honeycombing occurred in a floor slab due to poor workability of concrete and late placement during hot weather. Loose concrete was chipped and the area was grouted and repaired with a bonding agent and cementitious material. To prevent future issues, proper supervision of batching and placing is needed, discharge times must be monitored, pour areas kept clean, and skilled laborers used for concrete work.