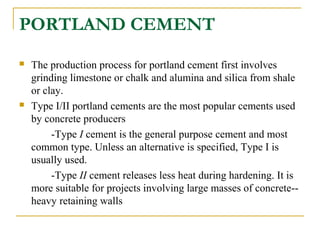

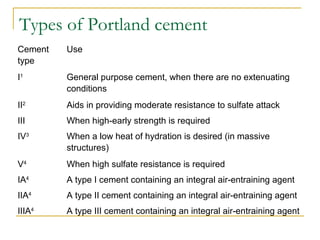

The document provides an outline for a presentation on concrete, cement, and construction materials. It includes sections on concrete properties and production, cement types, and common construction materials like asphalt and aggregate. Concrete is made from a mixture of cement, water, aggregates, and sometimes chemical admixtures. Proper mixing, placement, and curing are outlined as important for developing concrete's strength and durability. The most common cement is portland cement, and types I and II are generally used. Asphalt and aggregates are also highlighted as major construction materials.