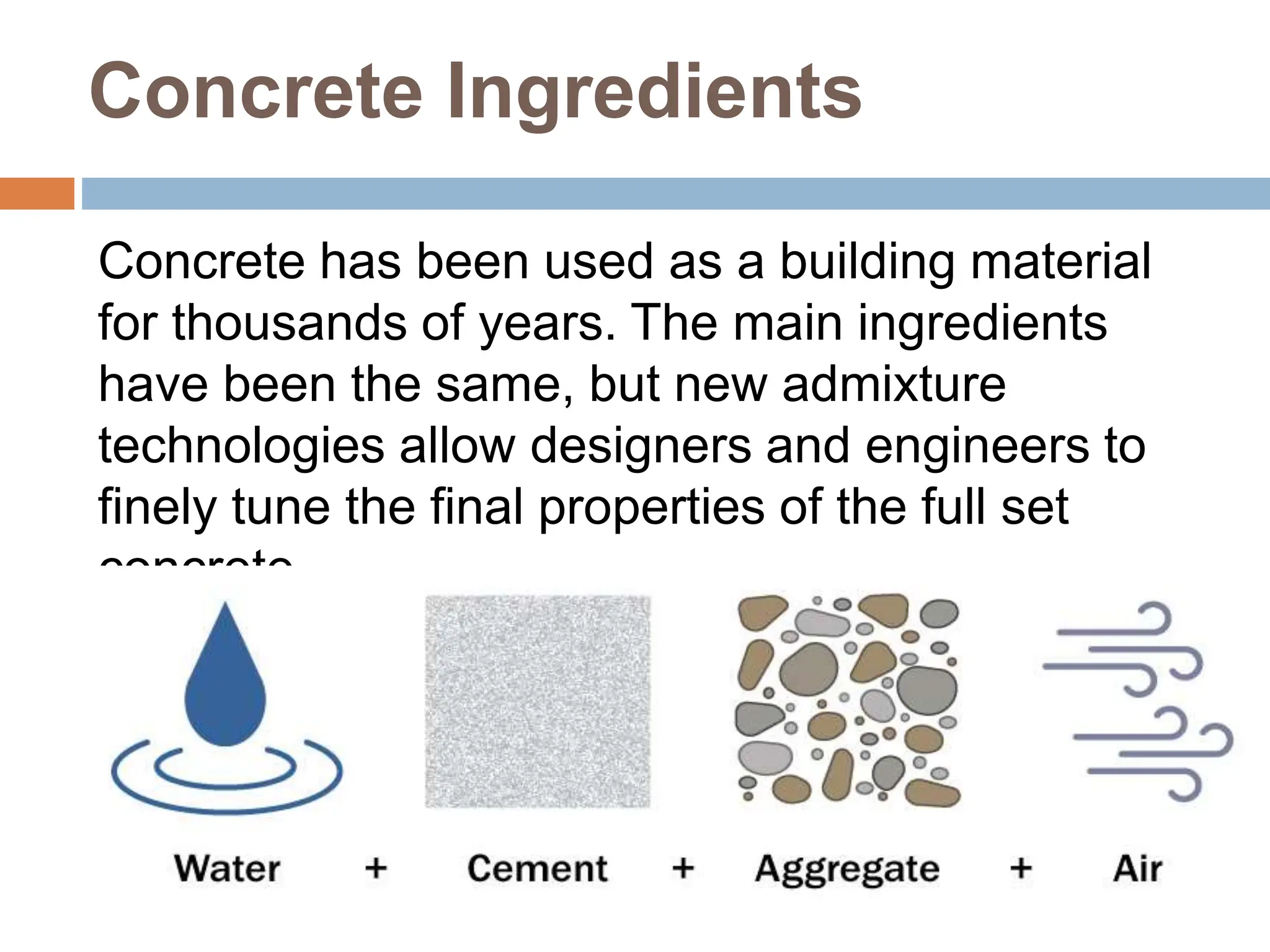

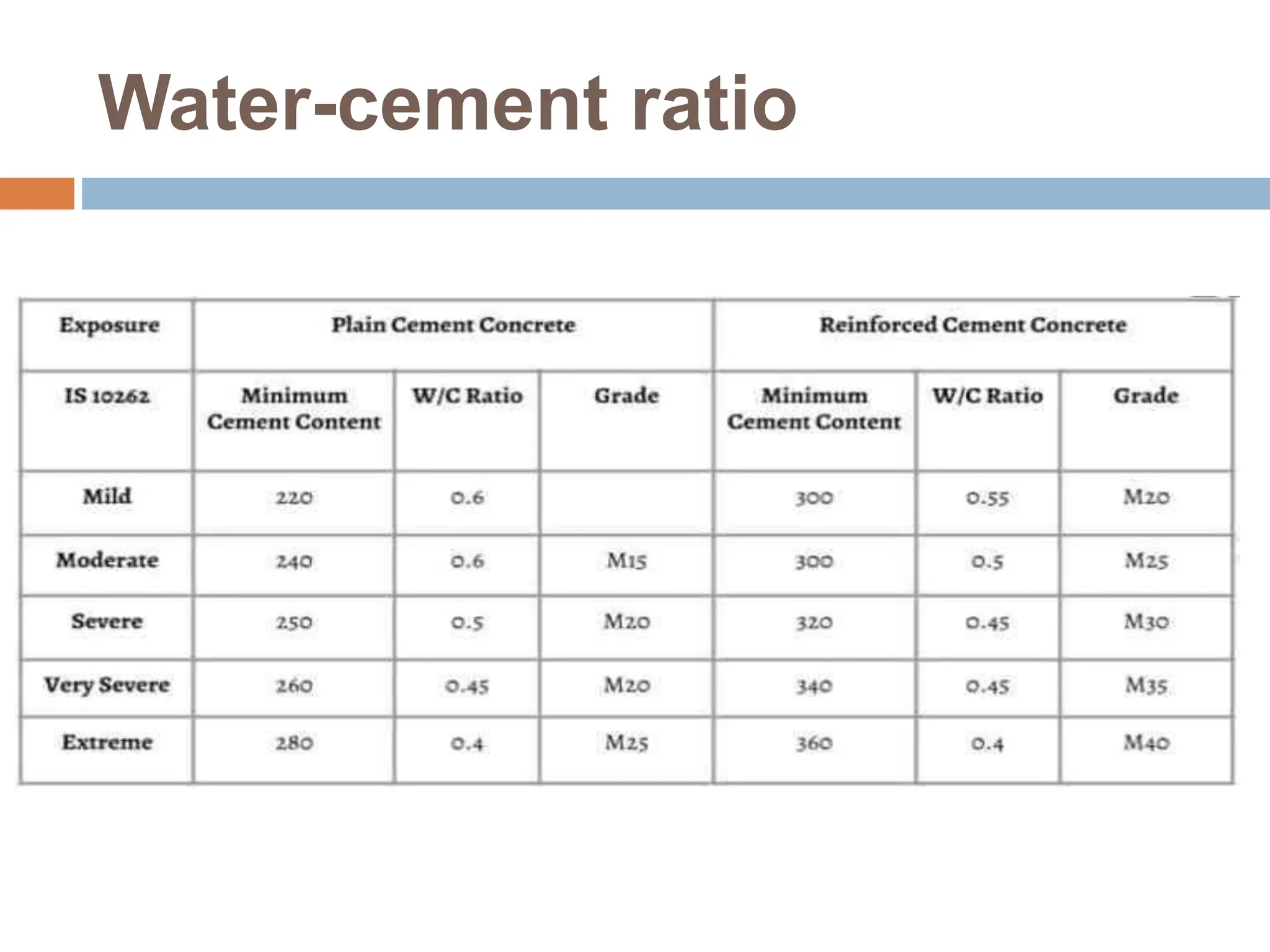

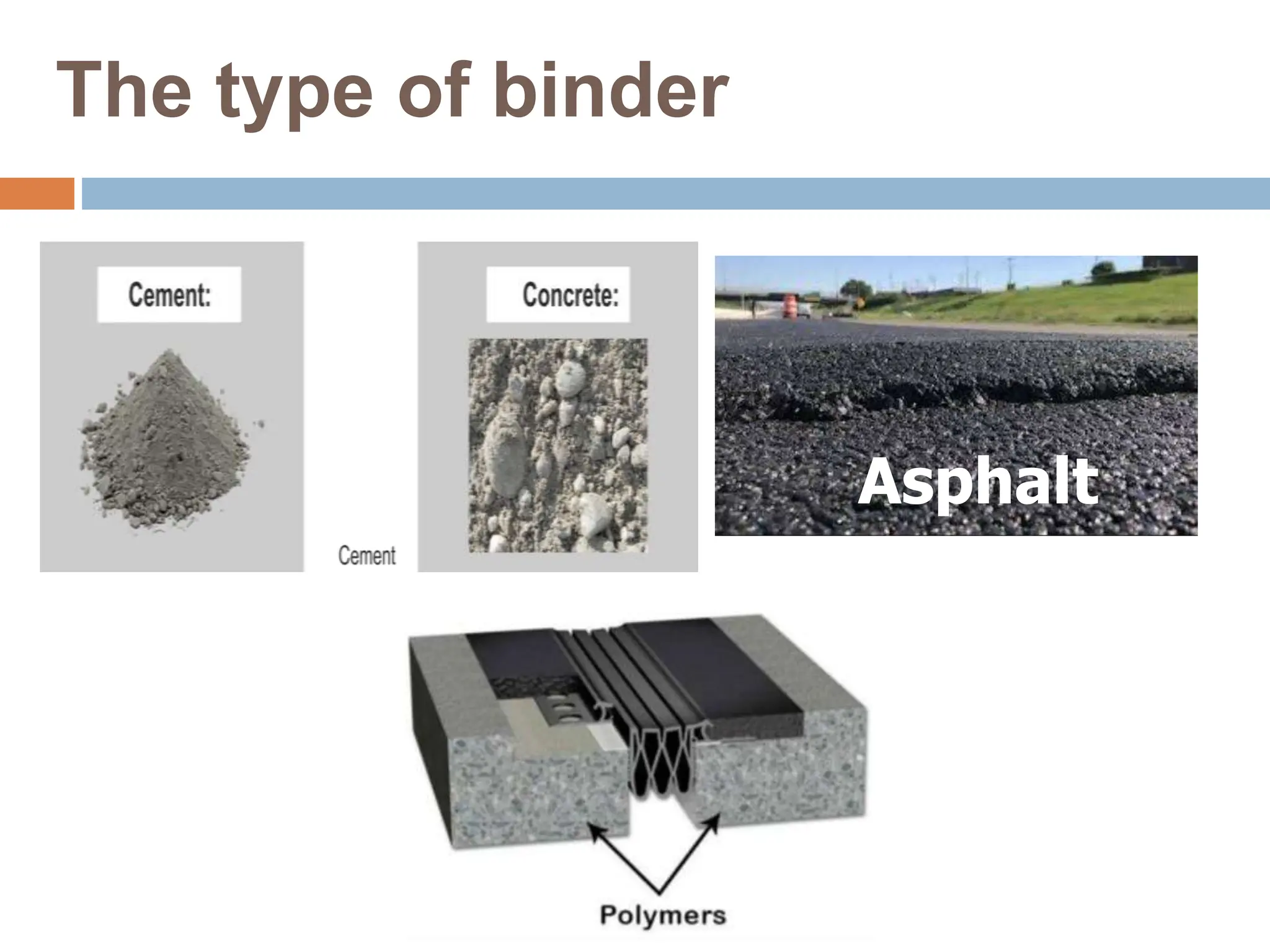

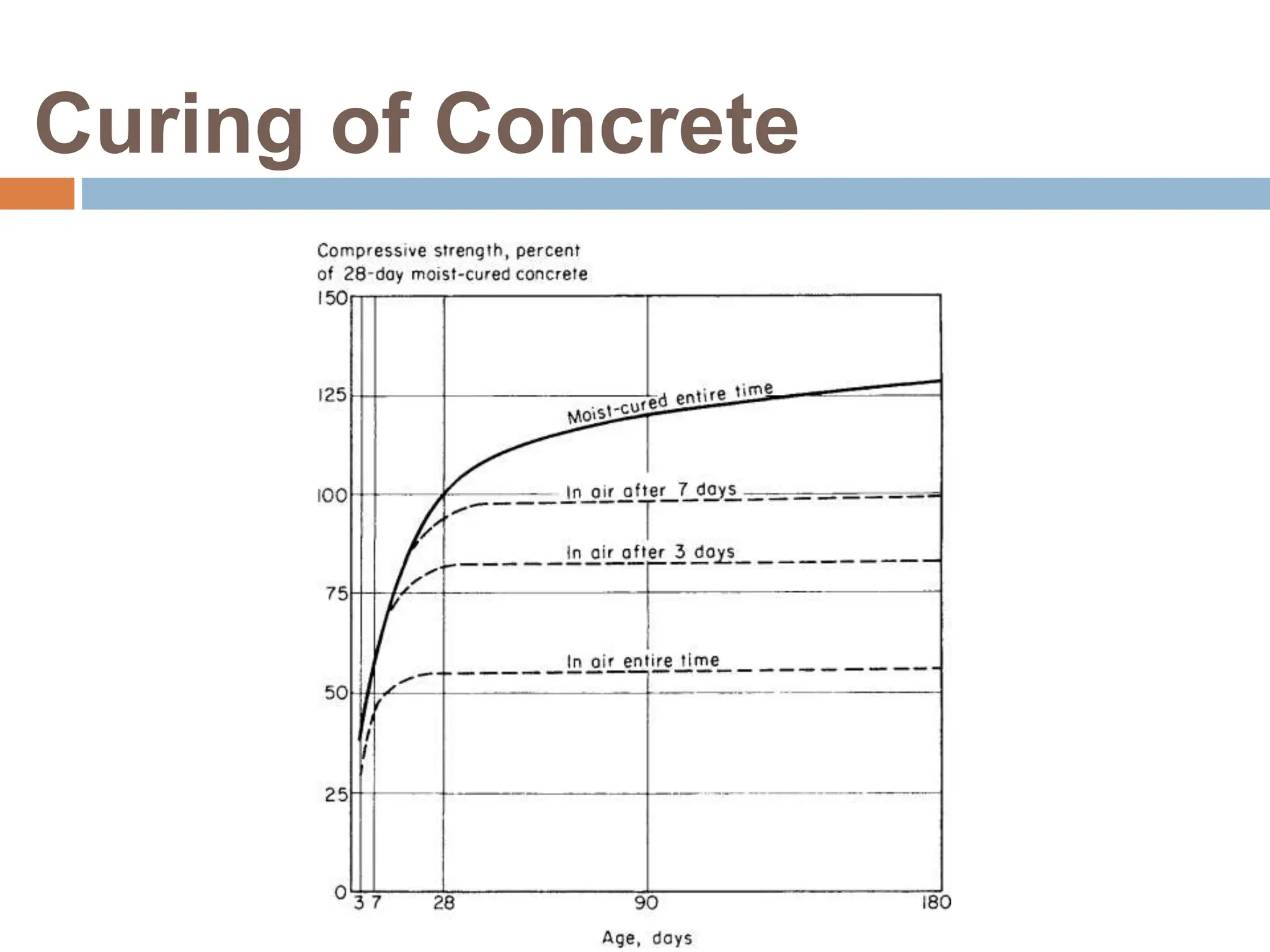

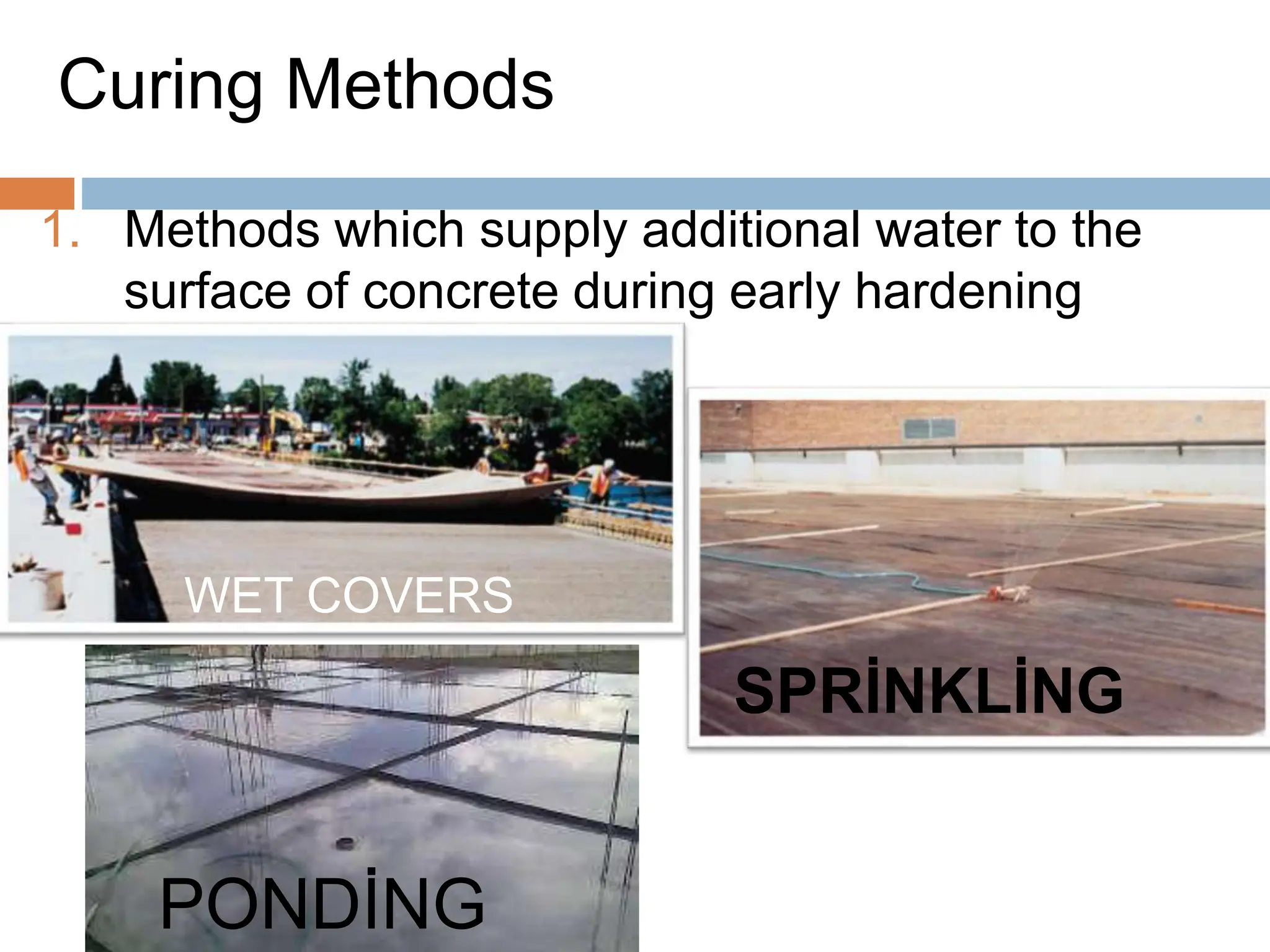

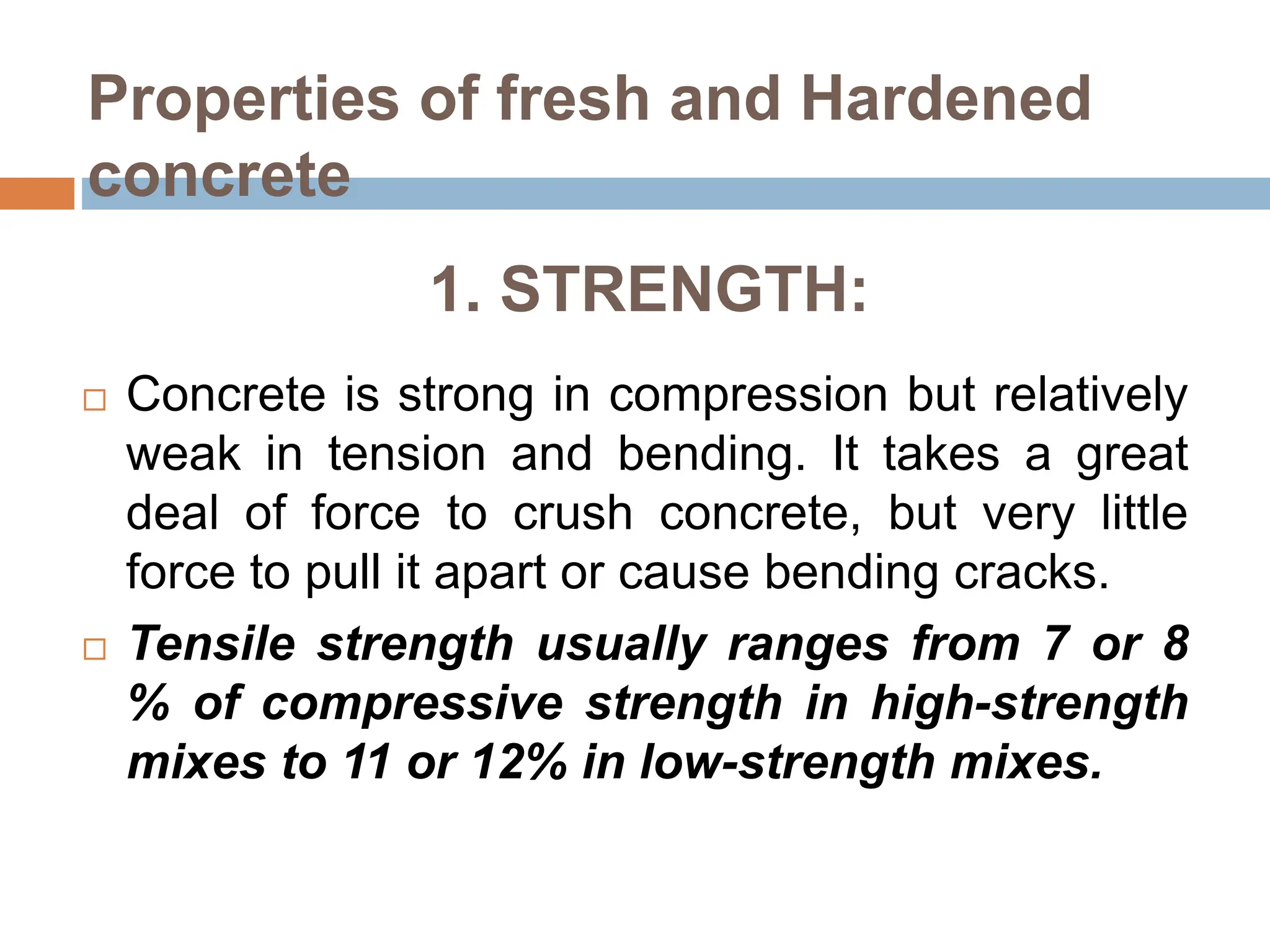

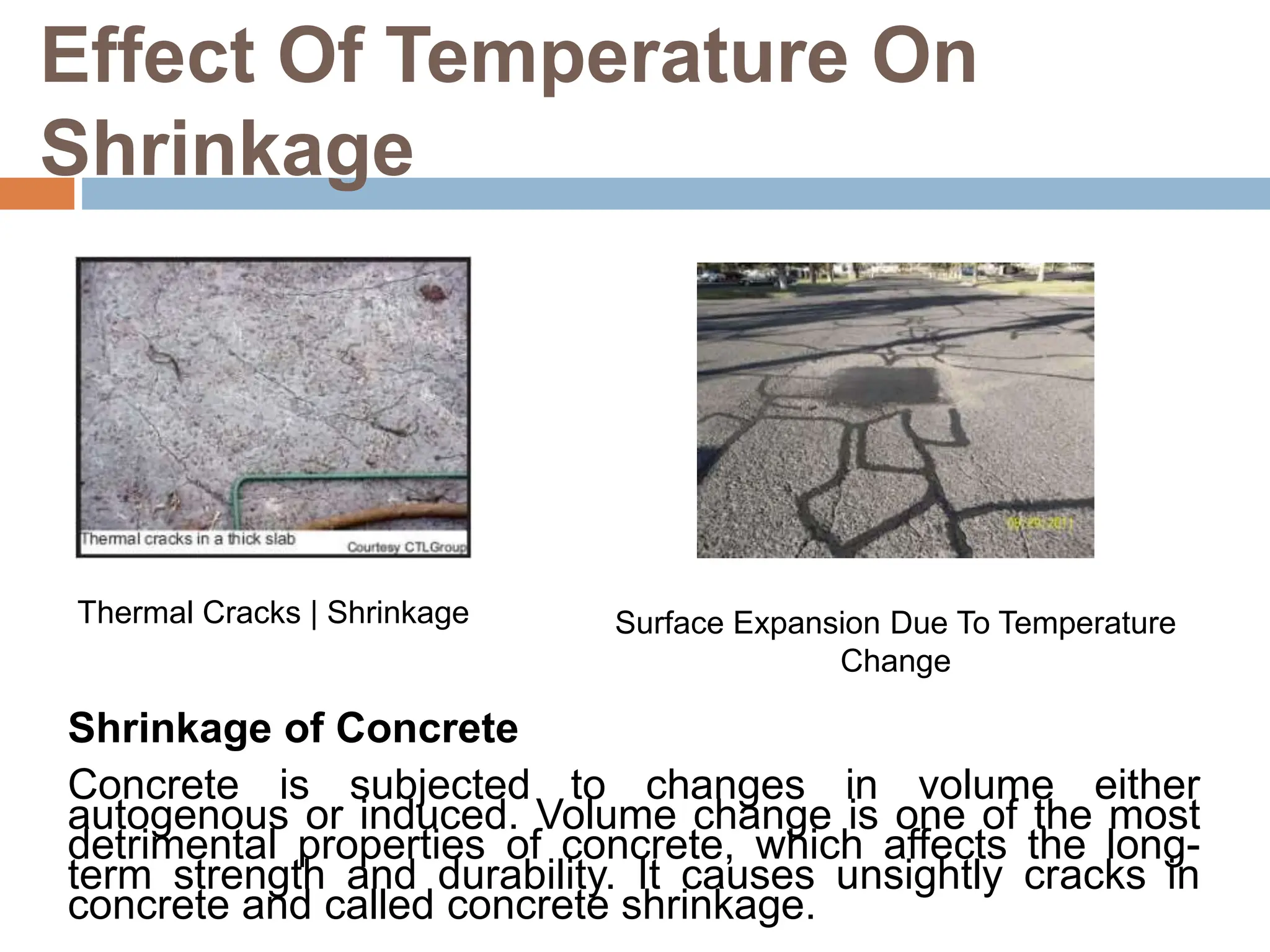

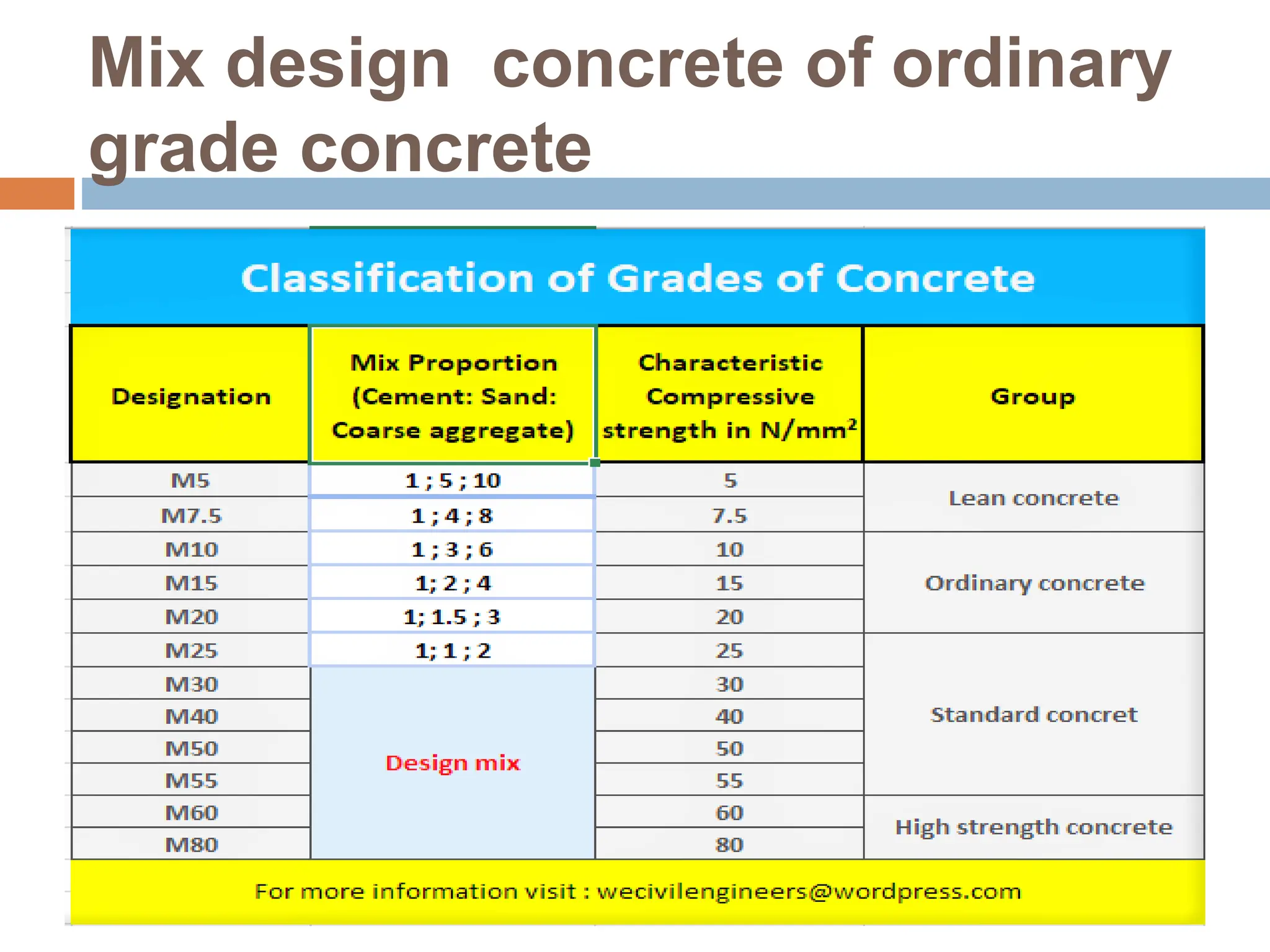

Concrete is a building material made by mixing cement, sand, gravel and water. It has high compressive strength but low tensile strength. Reinforced concrete uses steel bars to increase tensile strength. Concrete ingredients include cement, aggregates and water. Admixtures like accelerators and retarders are used to control setting time. Proper mixing, placing, compaction and curing are required to produce high quality concrete.