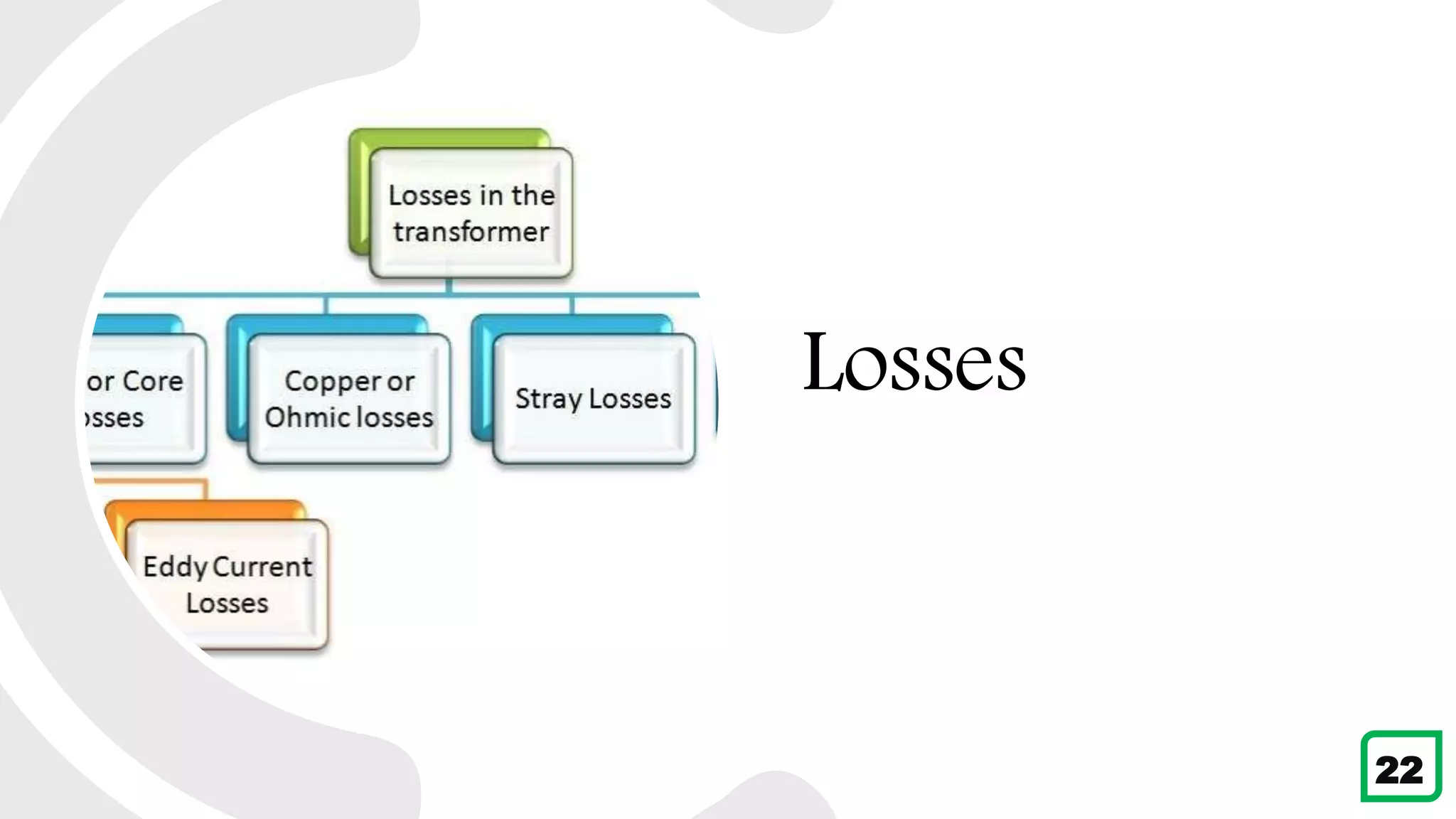

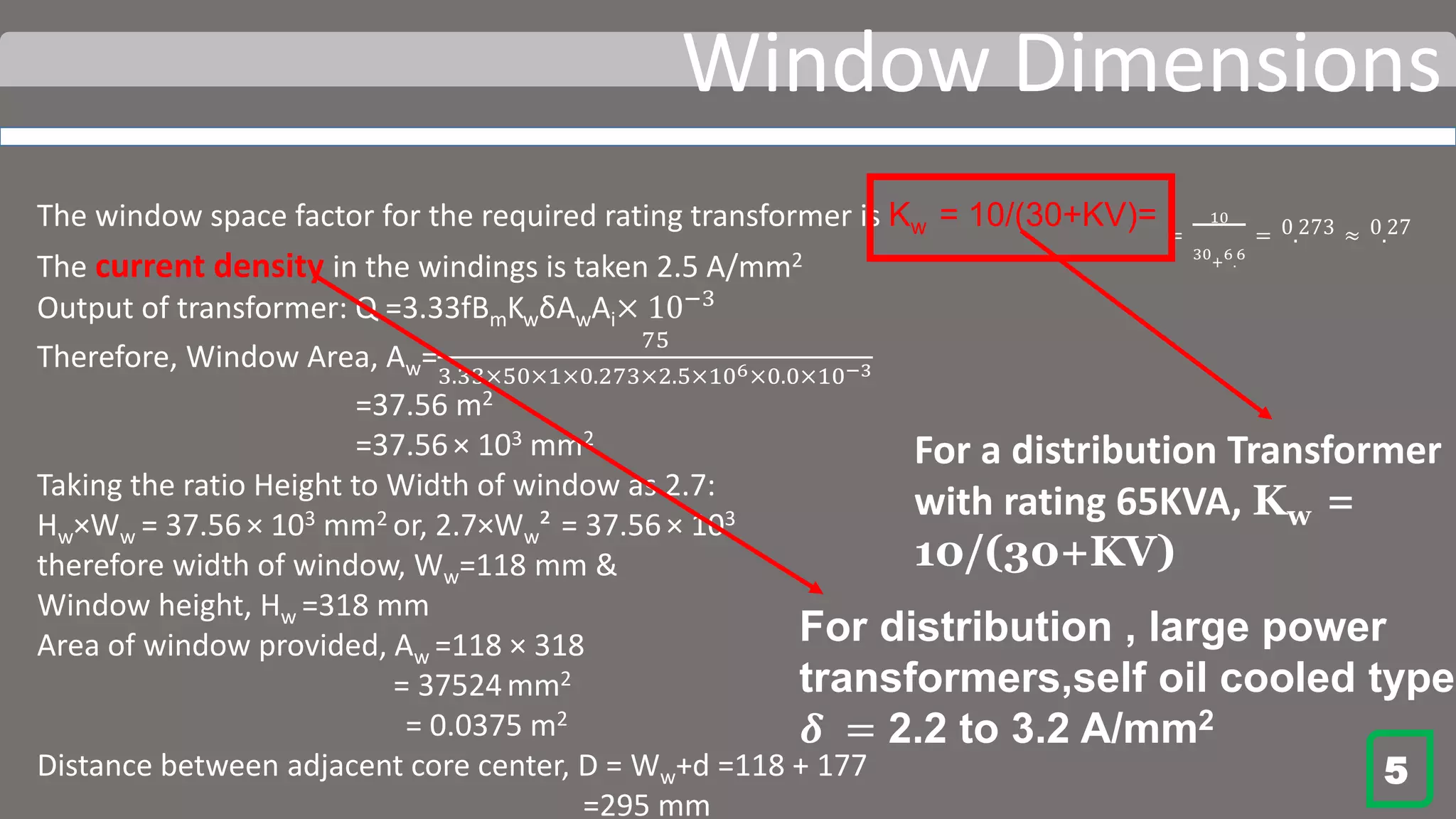

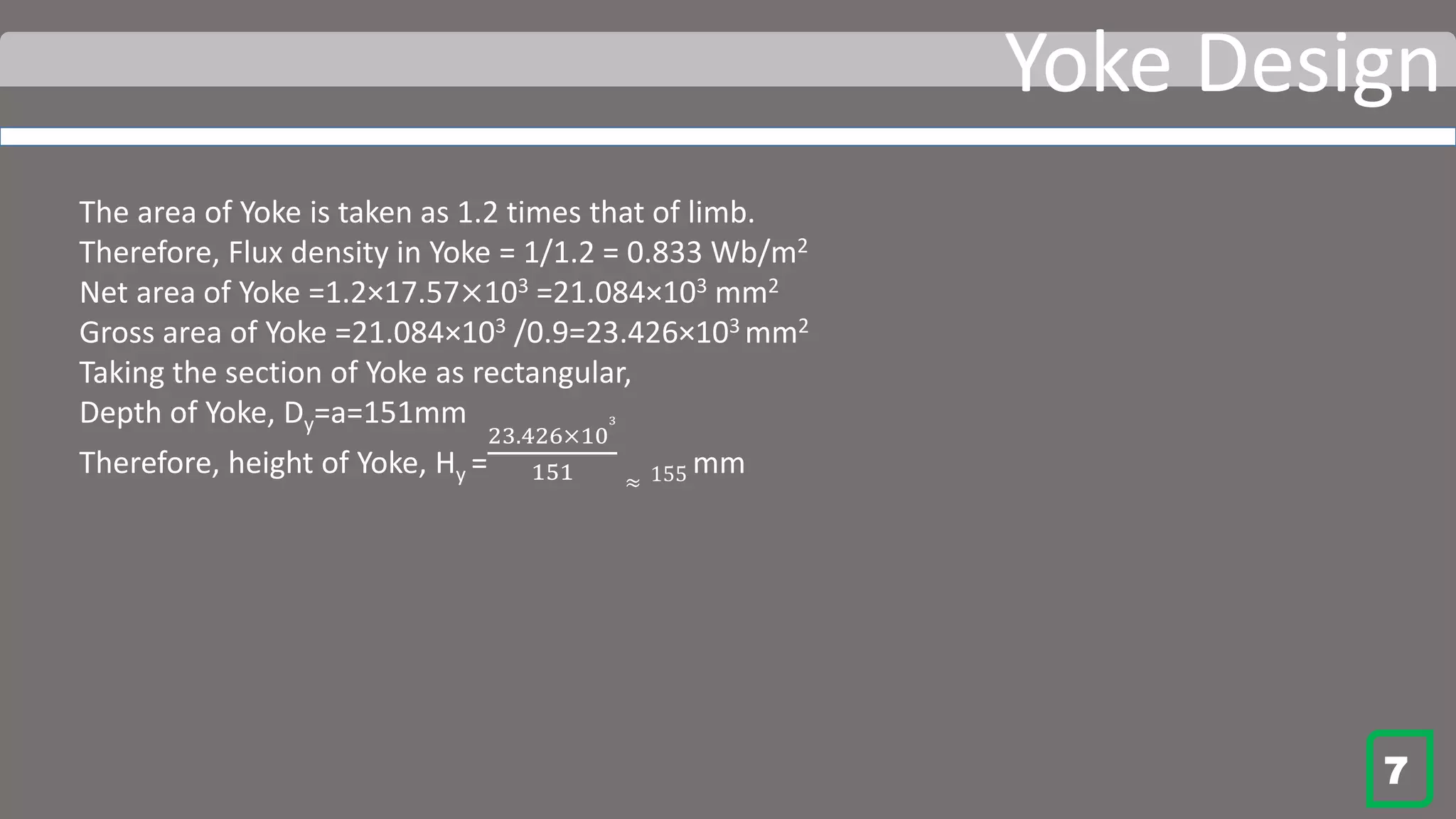

This document details the design process for a 65 kVA, 11 kV/400 V, 50 Hz, three-phase core type transformer. It outlines objectives, design requirements, calculations for dimensions, winding configurations, losses, and efficiency metrics, using specific formulas and materials such as silicon steel for the core. The final analysis indicates that additional cooling methods are necessary to maintain acceptable temperature levels during operation.

![Core Design

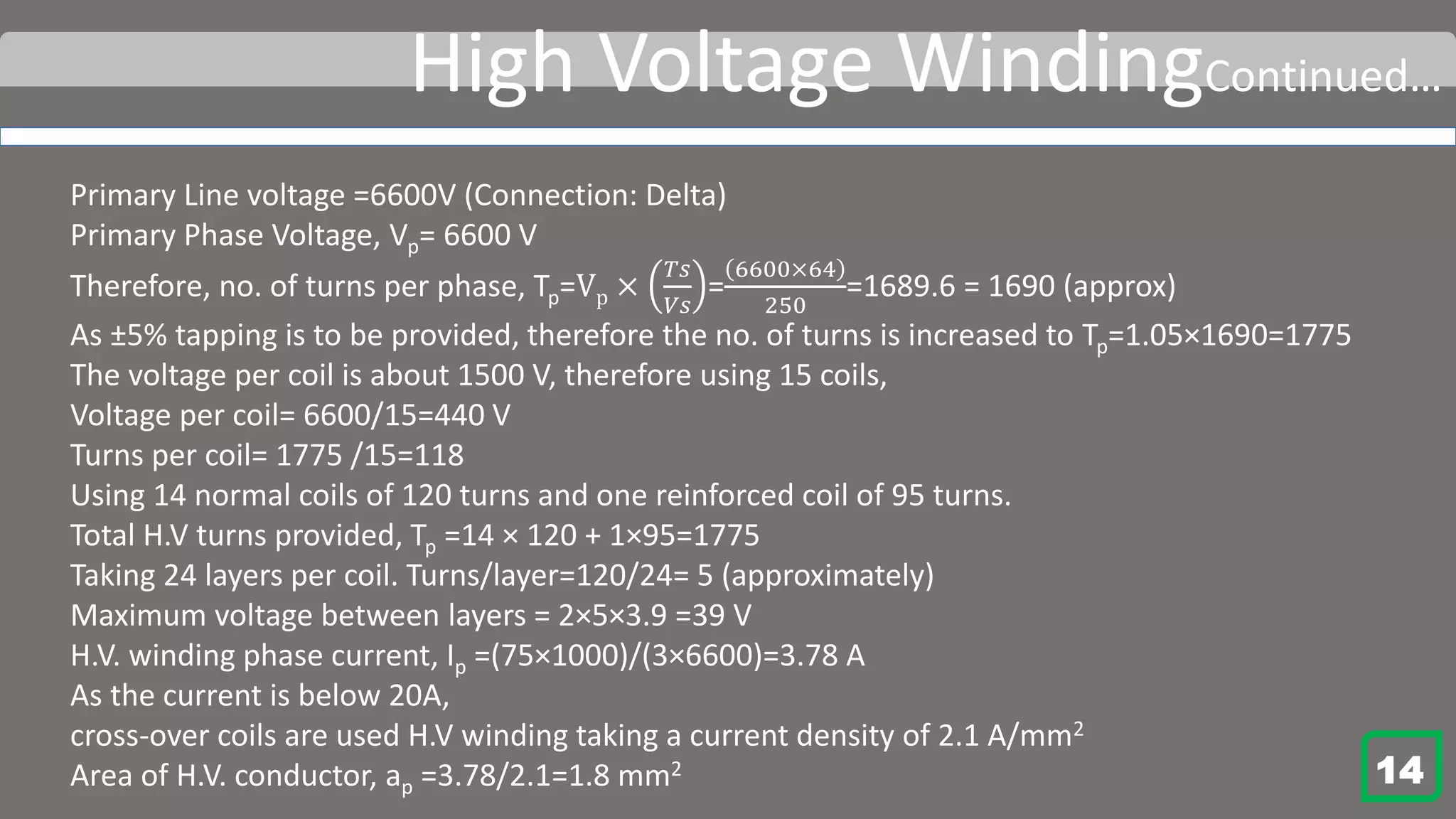

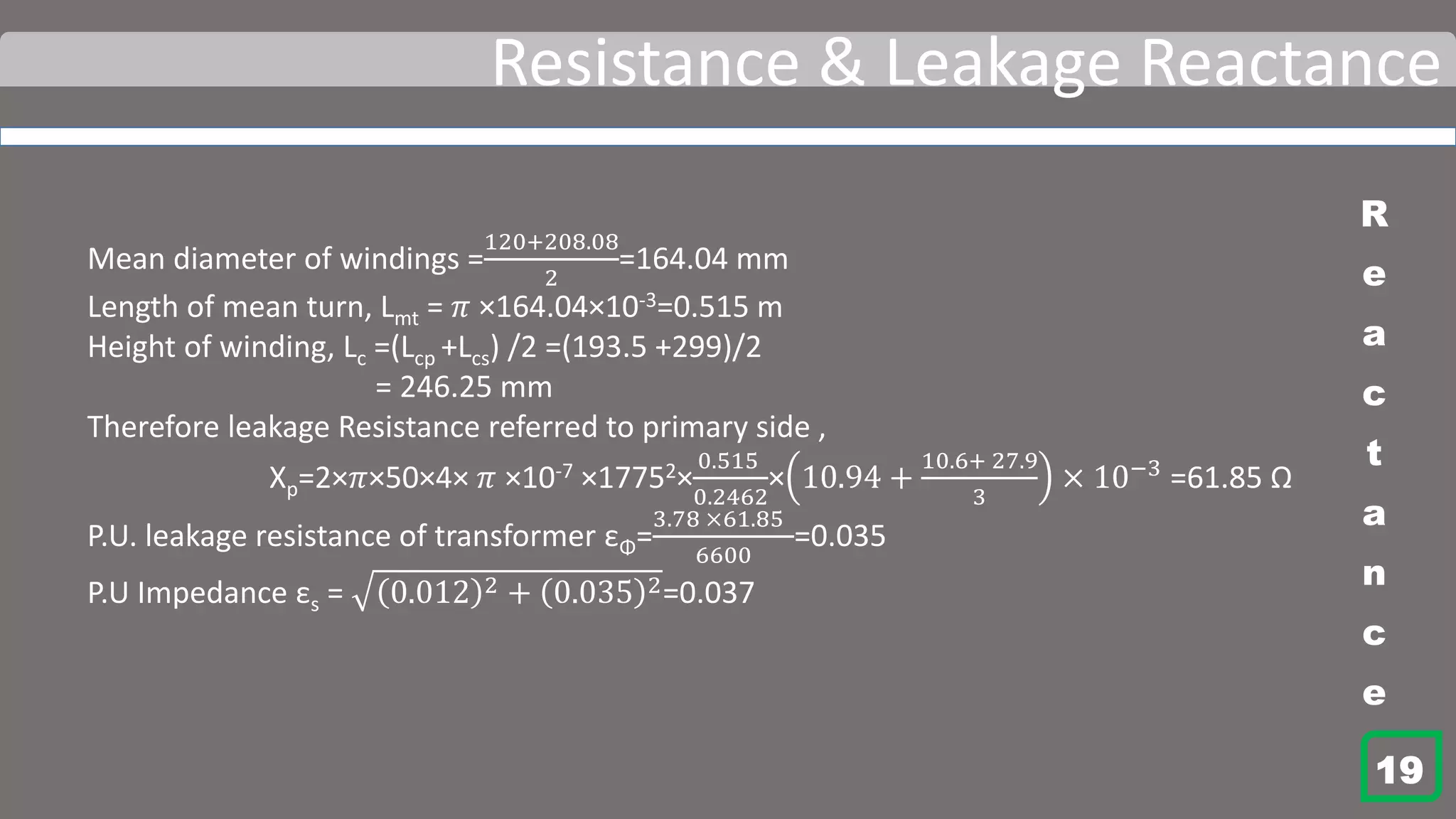

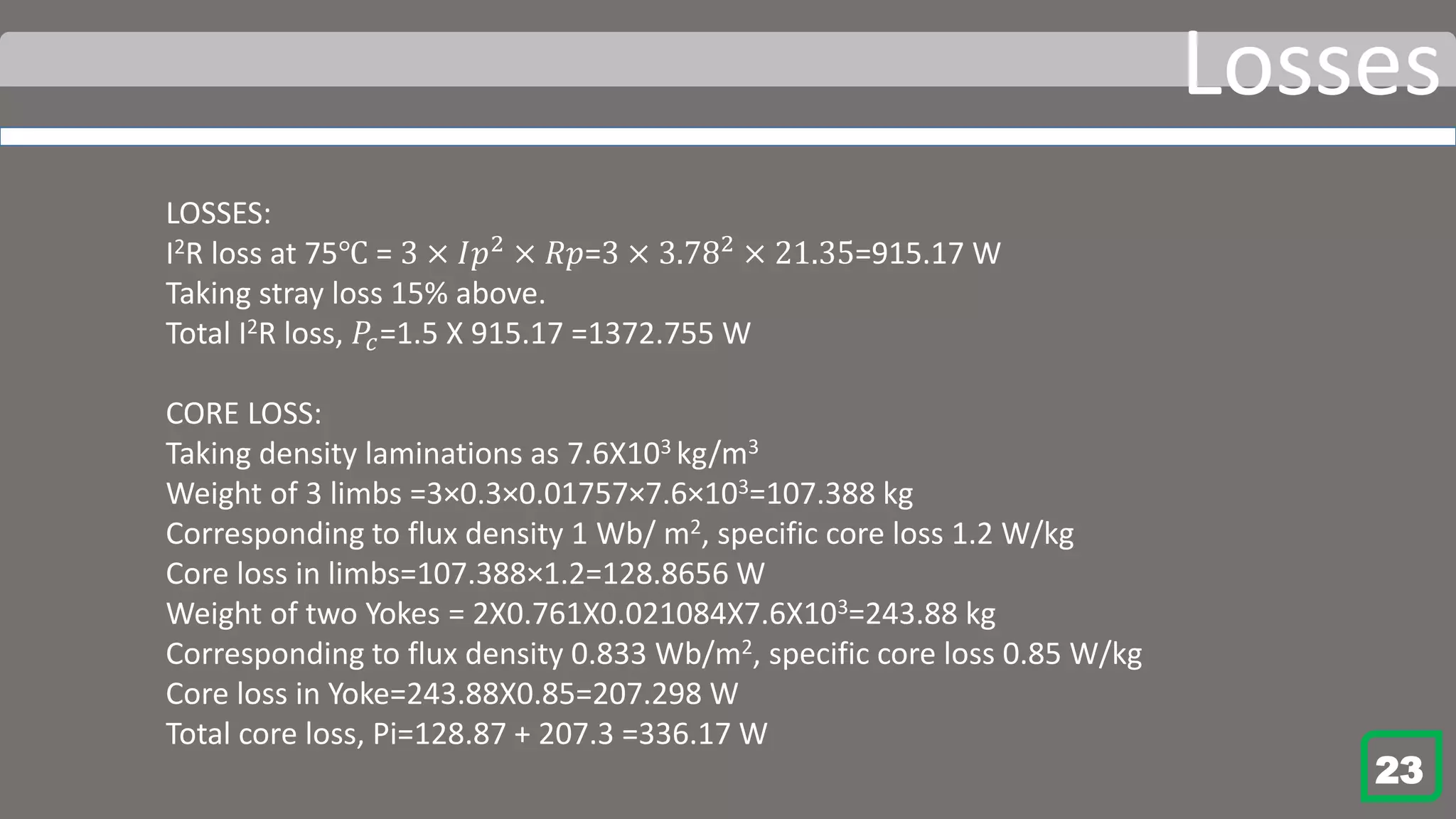

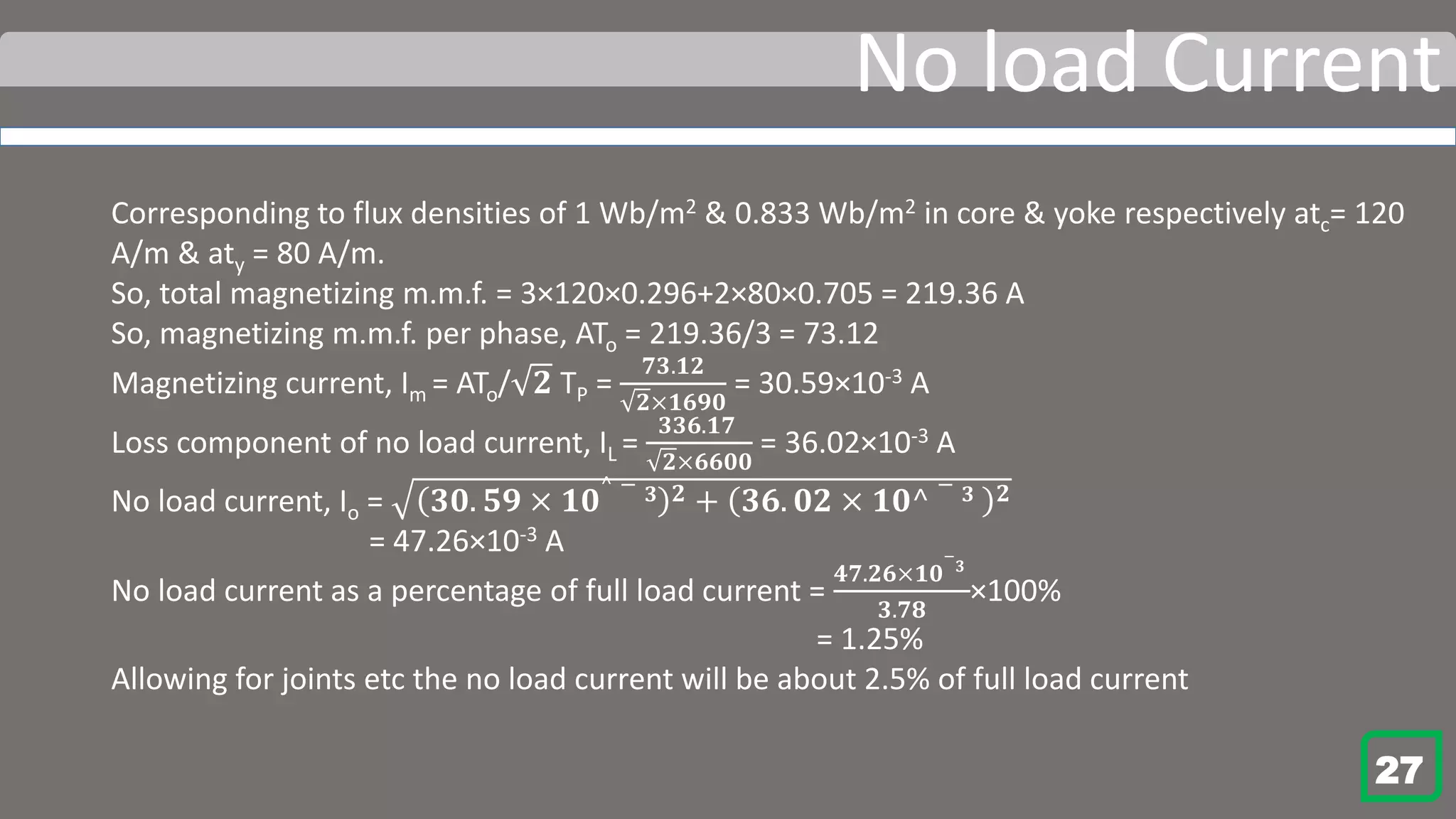

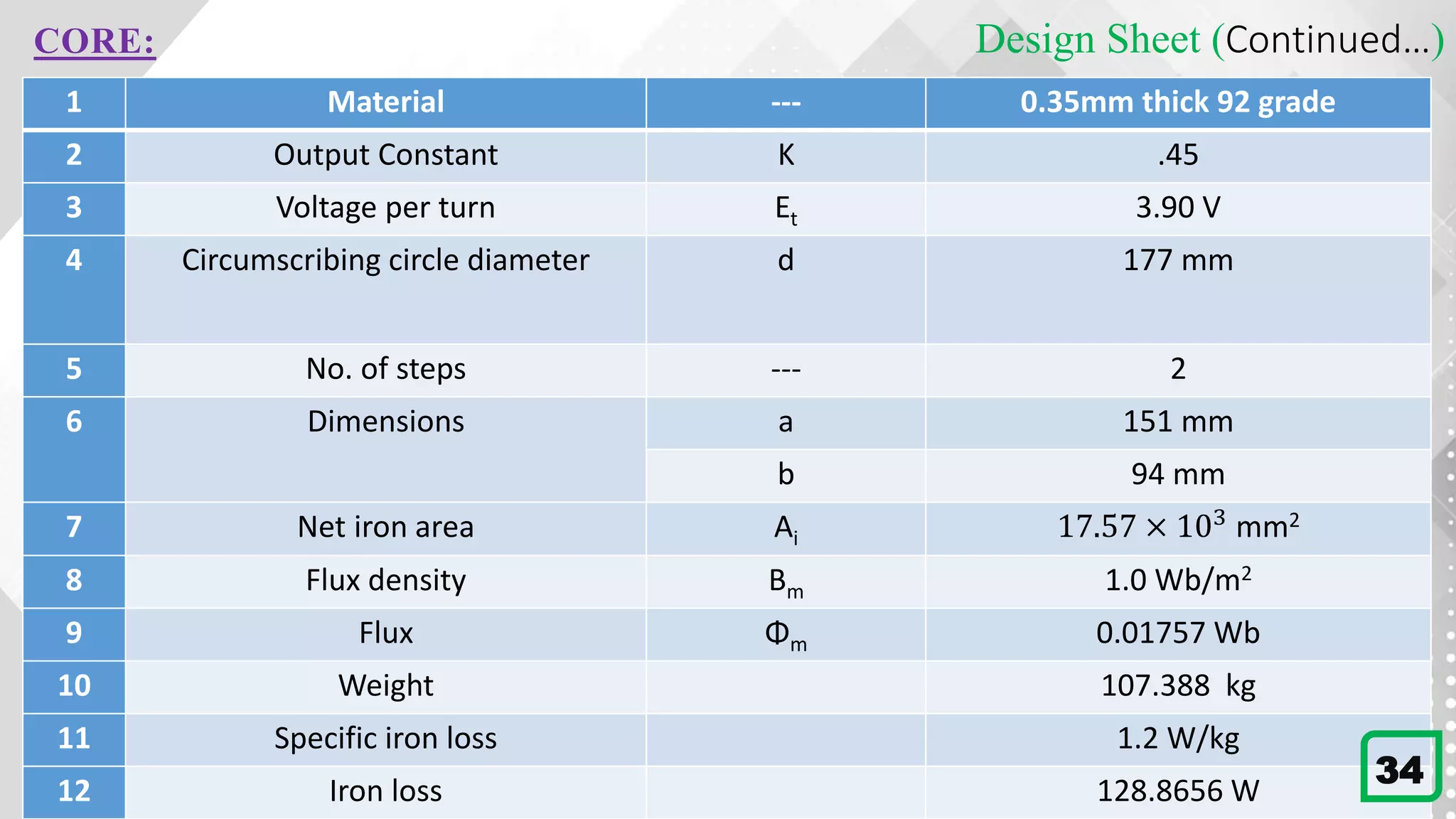

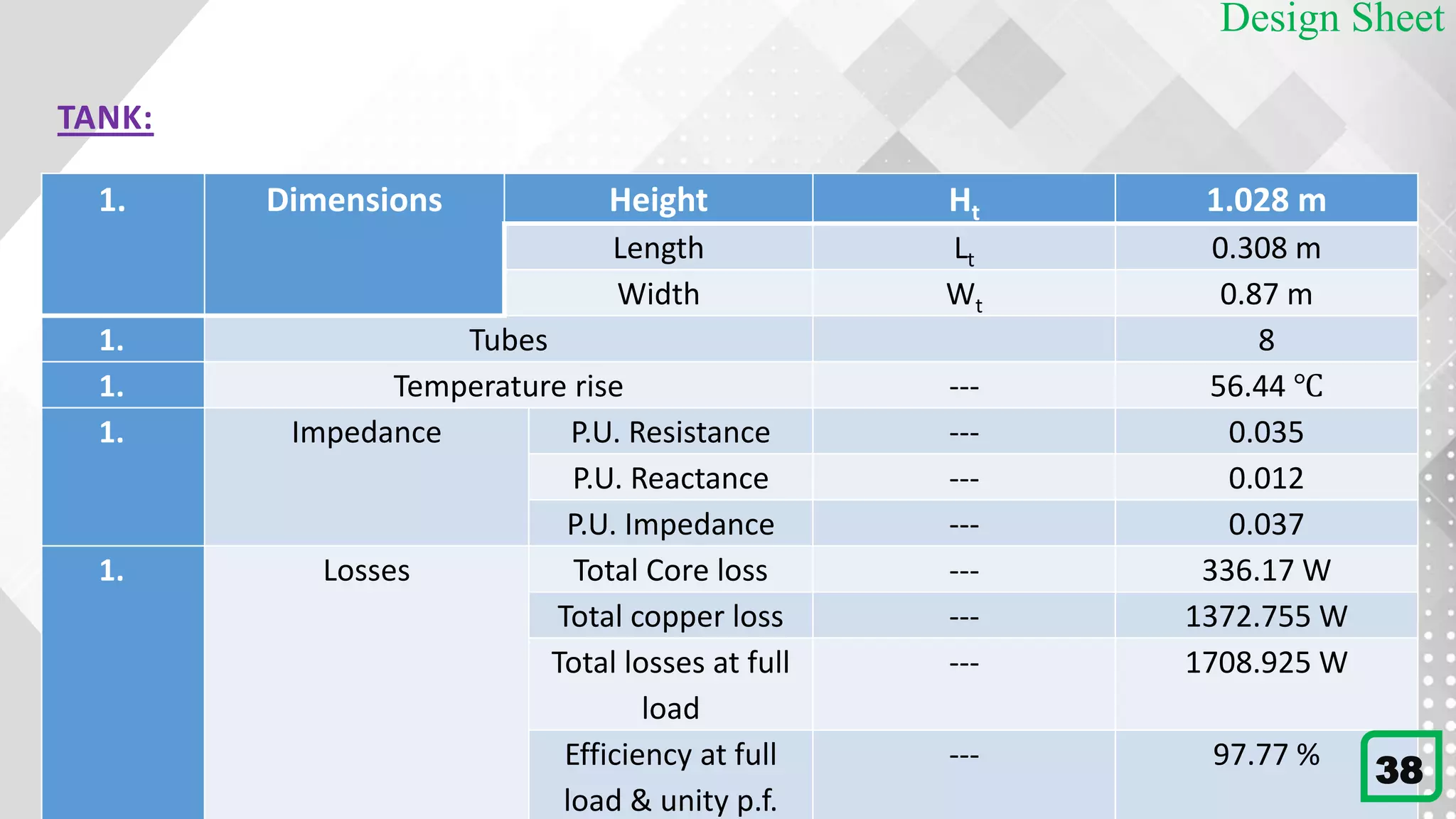

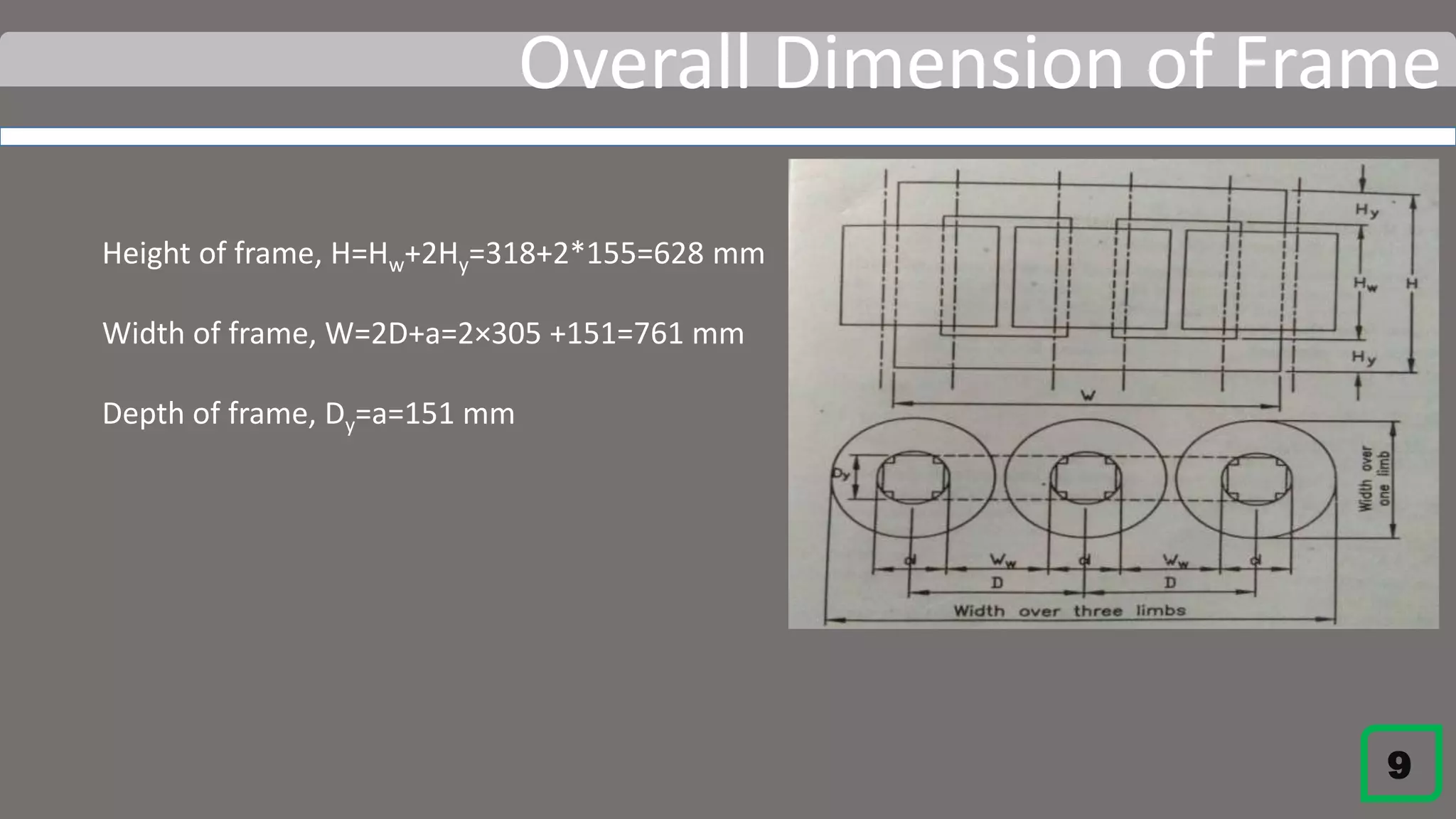

The value of k is taken from the table, [7.2 in A course in Electrical Machine Design. AK. Sawhney]

K=0.45 for 3-phase core type distribution transformer.

Voltage per turn Et =K 𝑄 =0.45 75 =3.90 V Therefore,

Flux in the core, Φm =

𝐸𝑡

4.44×𝑓

=

3.90

4.44×50

= 0.01757 Wb

Hot rolled silicon steel grade 92 is used. The value of flux density Bm is assumed as 1.0 Wb/m2.

Net iron Area Ai=

0.01757

1.0

= 0.01757 = 17.57×103 mm2

Using a cruciform core, Ai =0.56d2

Diameter of circumscribing circle, d =

17.57×103

0

.

56

=177.13 mm≈177 mm

Reference widths of laminations:

a=0.85d=0.85×177 =150.45 mm

b=0.53d=0.53×177=93.81 mm

The nearest standard dimensions are: a =151 mm and b =94 mm

3

Type K

Single phase shell type 1-1.2

Single phase core type 0.75-0.85

Three phase shell type 1.3

Three phase core

type(distribution)

0.45

Single phase shell

type(power)

0.6 to 0.7

Area percentage

of circumscribing

circle

Square Cruciform Three

Stepped

Four

step

Net core area,Ai 0.45 0.56 0.6 0.62](https://image.slidesharecdn.com/transformerdesign-200604230524/75/Project-on-Transformer-Design-Electrical-Machine-Design-5-2048.jpg)

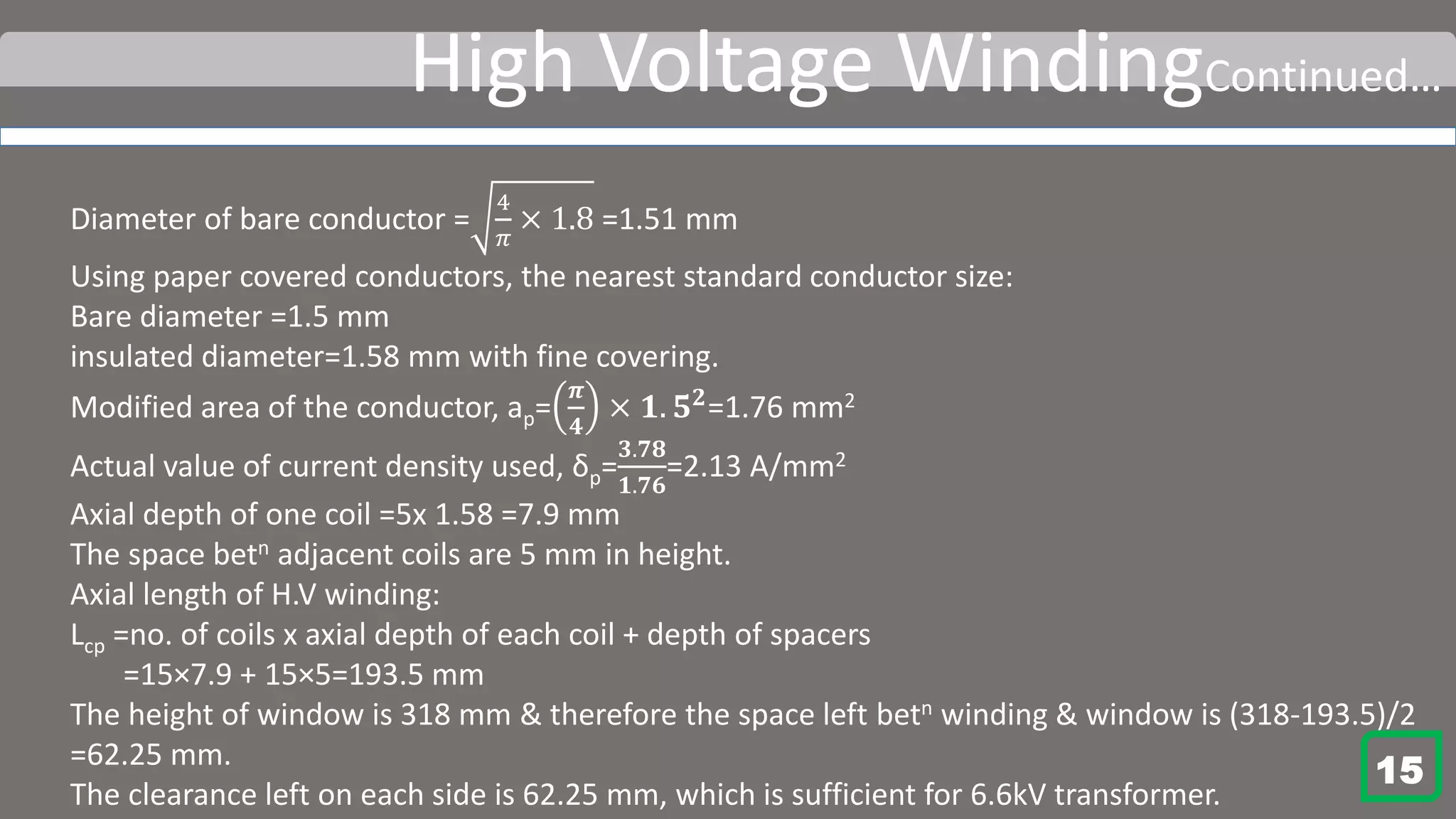

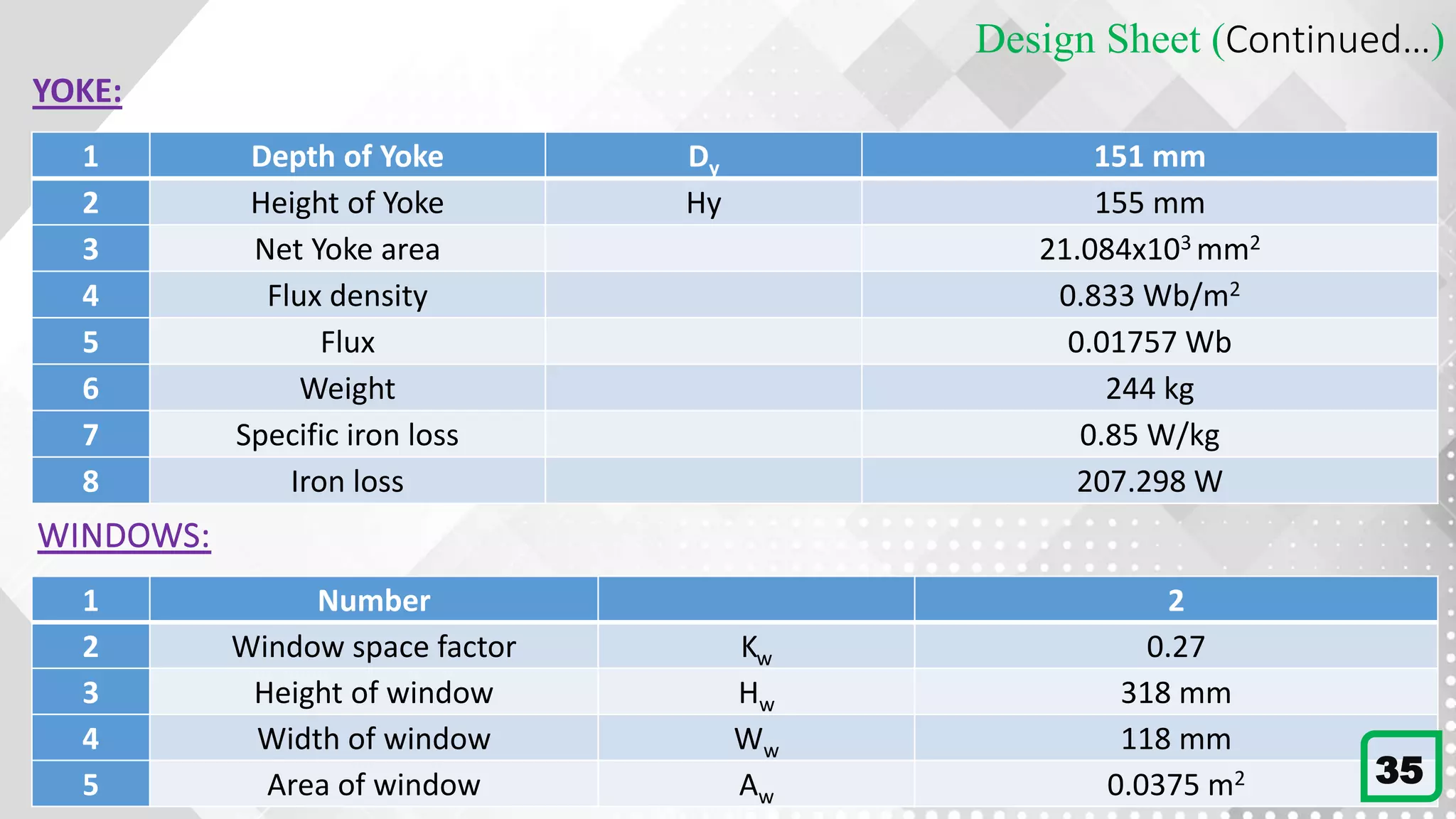

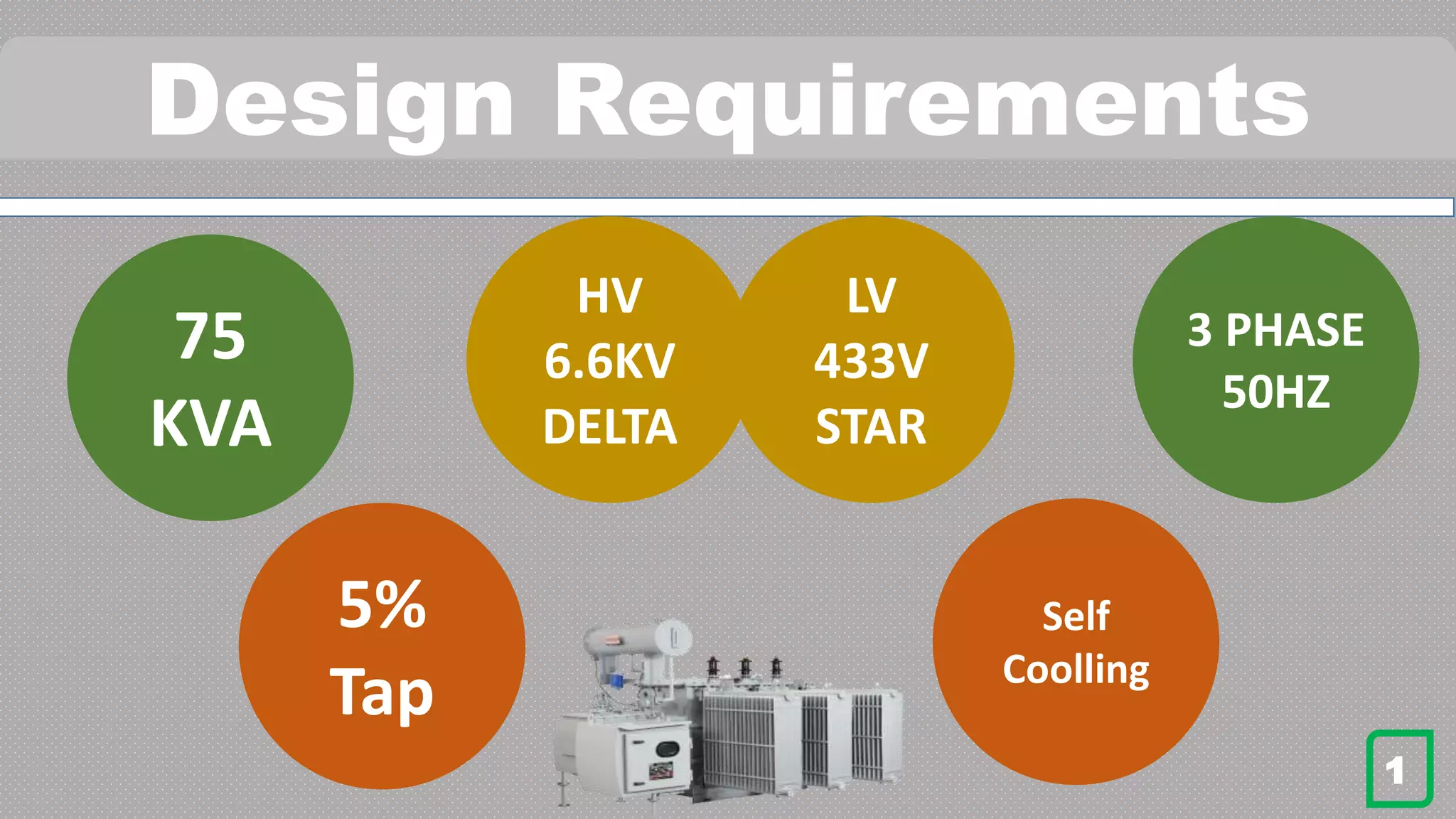

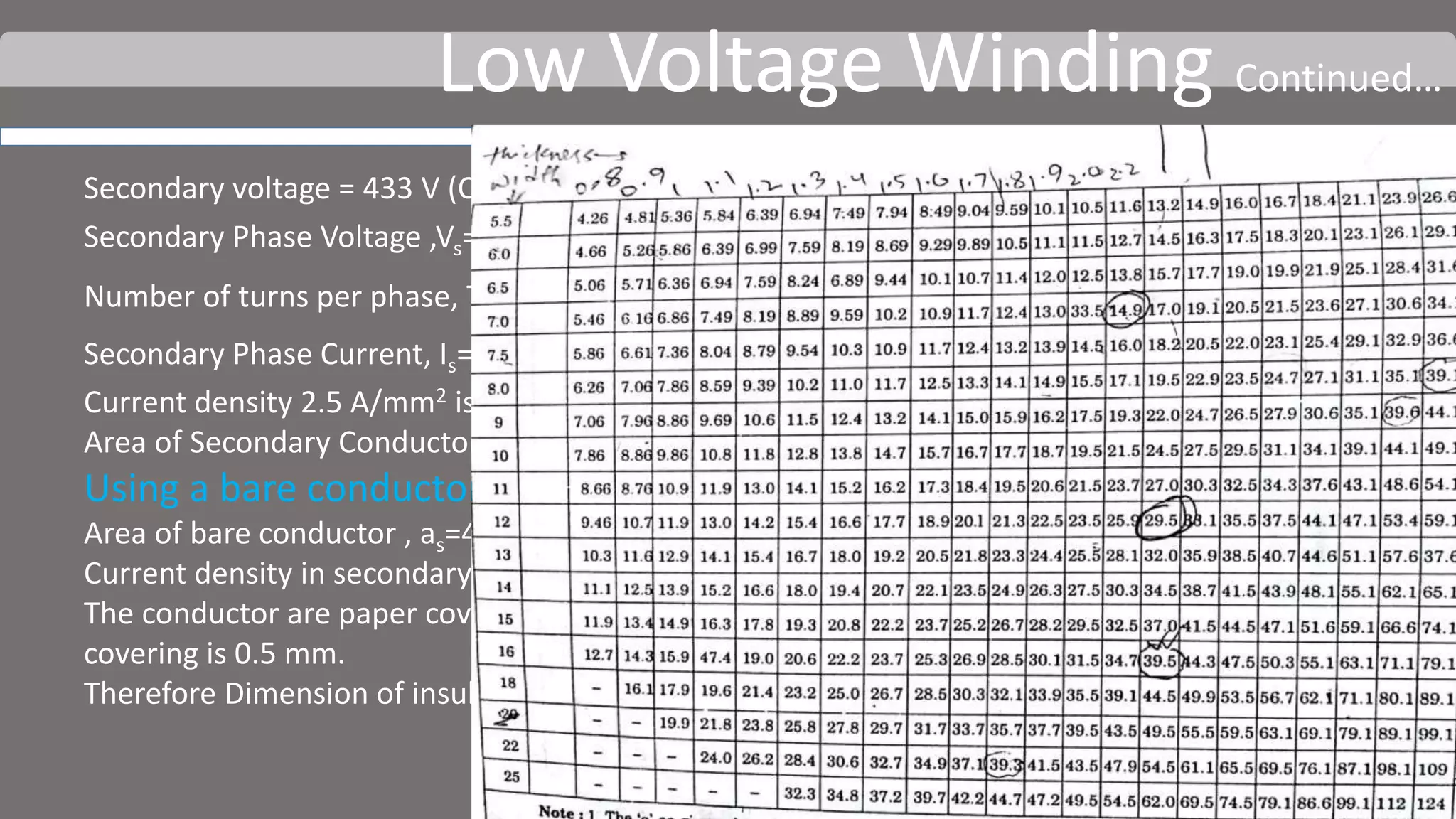

![Low Voltage Winding

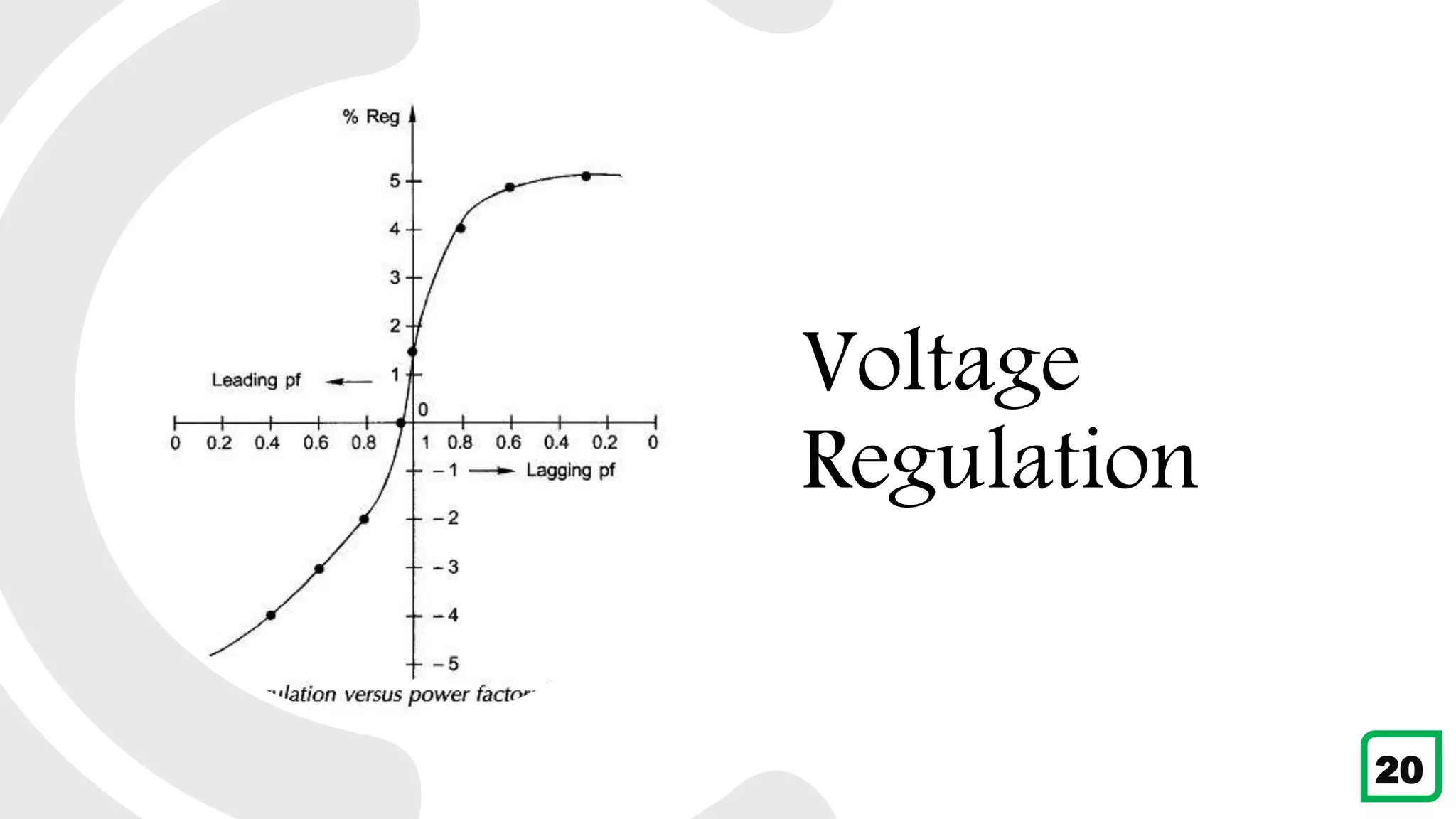

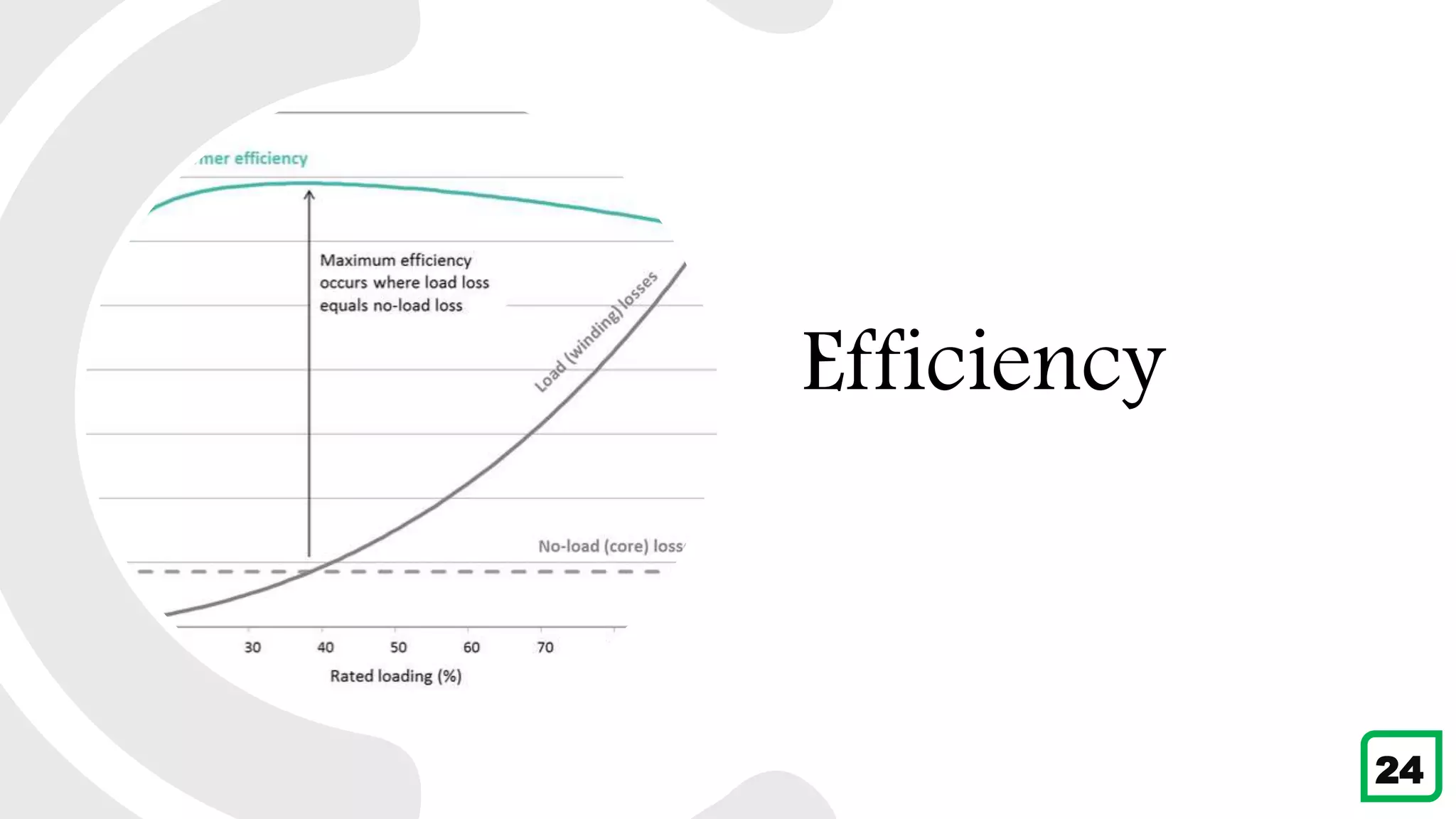

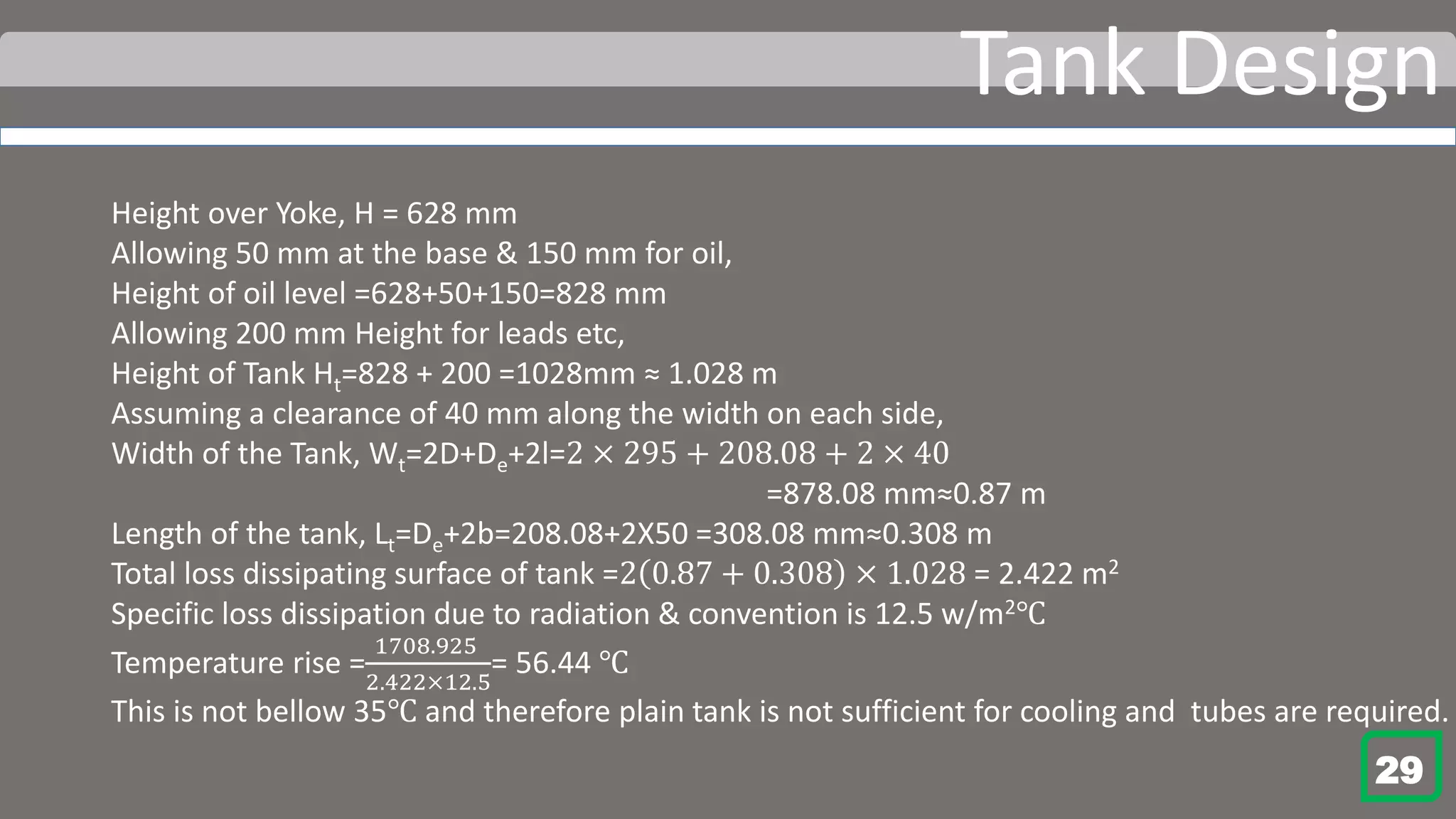

Using 3 layers for the winding.

Helical winding is used. Therefore, space has to be provided (

𝑇𝑠

3

+ 1)=(

64

3

+ 1) =22.3= 23 (approx)

turns along the axial depth.

Axial depth of L.V winding, Lcs =23×13=299 mm

The Height of window is 486 mm. This leaves a clearance of (318-299)/2=9.5 mm of each side of the

windings. [Which fulfill the minimum requirement 6 mm]

Radial depth of low voltage winding,

bs=no. of layers x radial depth of conductor + insulator betn layers

=3×3.2+2×0.5 = 10.6 mm

Diameter of circumscribing circle, d =177 mm

Using pressboard wraps 1.5 mm thick as insulation between l.v. winding and core.

Inside diameter of l.v. winding=117+1.5×2=120 mm

Outside diameter of l.v. winding= 120+10.6 =130.6 mm 12](https://image.slidesharecdn.com/transformerdesign-200604230524/75/Project-on-Transformer-Design-Electrical-Machine-Design-14-2048.jpg)