This document discusses compressors and reciprocating compressors specifically. It provides details on:

- How compressors work to compress gases from lower to higher pressures using mechanical energy.

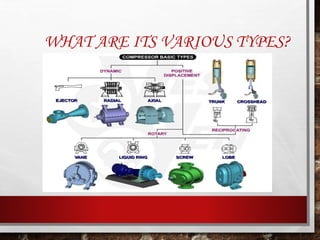

- The main types of positive displacement compressors, including rotary and reciprocating compressors.

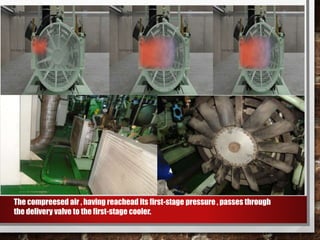

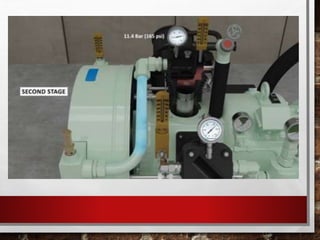

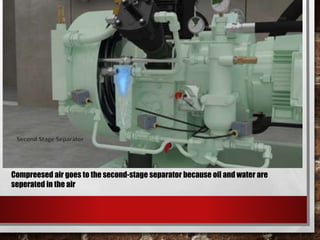

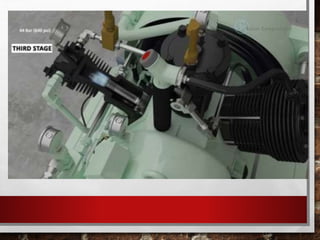

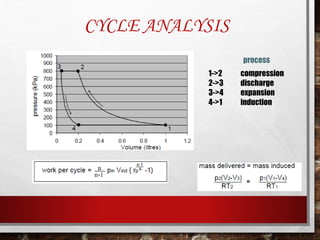

- The basic operating cycle of a reciprocating compressor, involving intake, compression, discharge, and expansion stages.

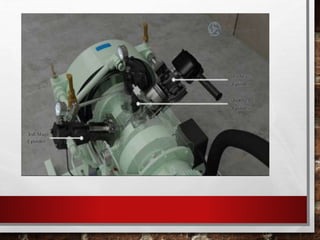

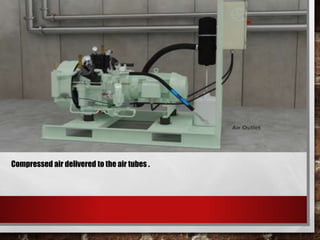

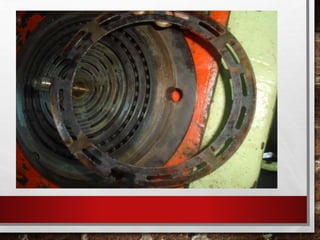

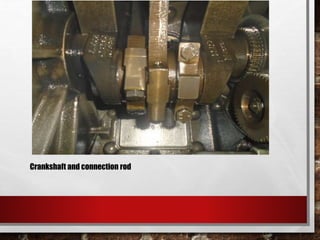

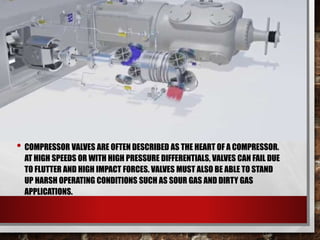

- Key components of a reciprocating compressor like valves, cylinders, coolers, and how compressed air is delivered.