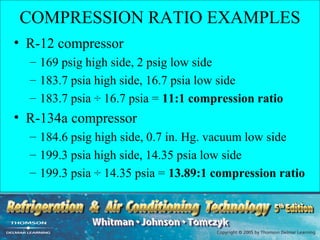

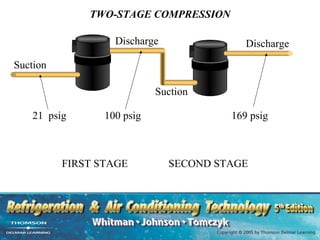

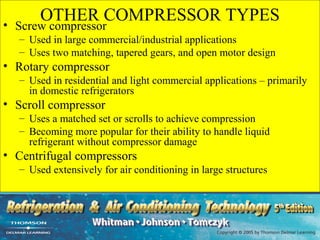

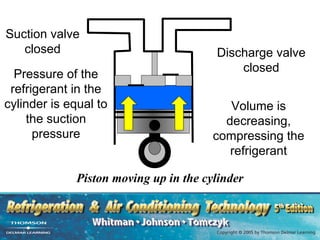

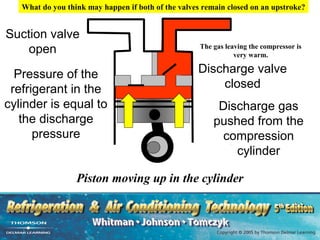

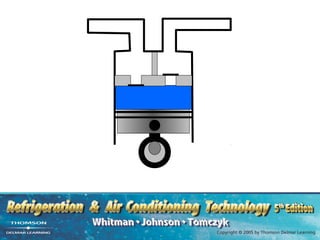

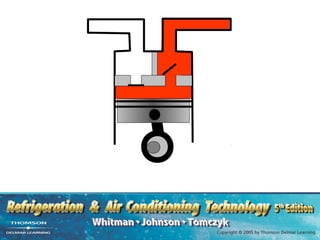

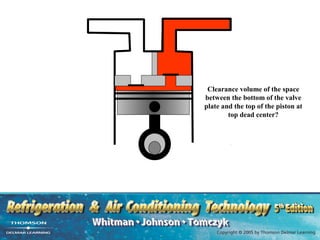

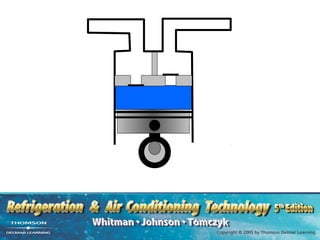

The compressor is the heart of refrigeration systems. It lowers pressure on the suction side and raises pressure on the discharge side. Compression ratio compares these pressures. Two-stage compression uses two compressors to lower the ratio. Common compressor types include reciprocating, screw, scroll, and centrifugal. Proper maintenance keeps the ratio low and prevents liquid slugging which can damage compressors.