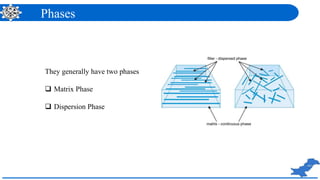

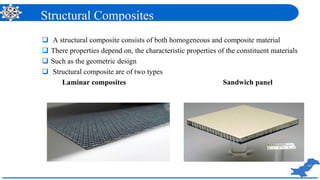

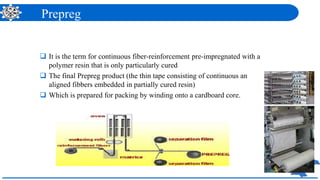

The presentation discusses composite materials, explaining their definition, properties, classification, and manufacturing processes. Key points include the advantages and drawbacks of composites, their applications in various industries, and the factors affecting their microstructure and performance. It also addresses potential failures that can occur in composite materials.