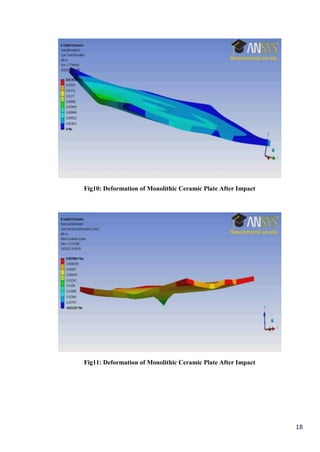

The document is a seminar report on ceramic composites for ballistic impact protection. It provides background on composites and ceramics, including their constituents, processing methods, and applications such as aerospace and military armor. The report describes a case study comparing the ballistic impact performance of steel plates, monolithic ceramic tiles, and ceramic composite tiles. Ceramic composites were found to provide the best solution by reinforcing ceramics to improve multi-hit capability while maintaining strength and reducing weight compared to steel.