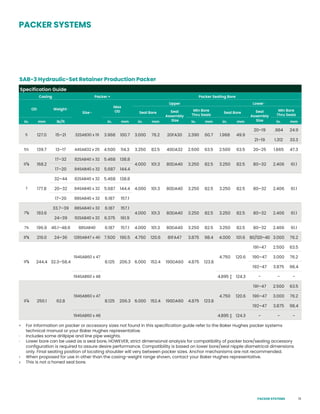

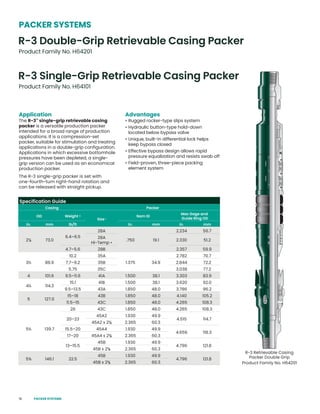

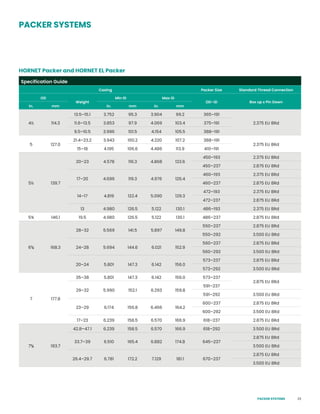

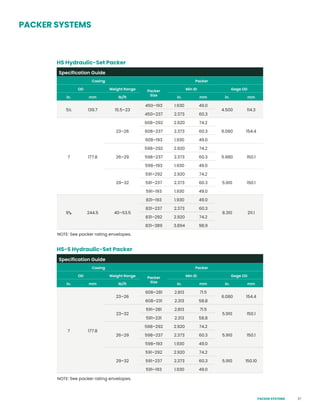

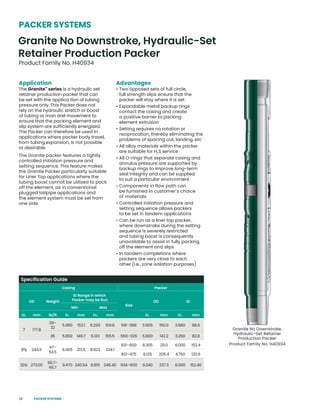

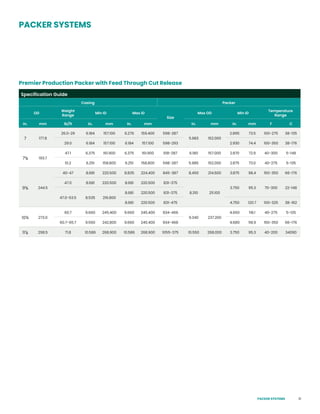

The document is a comprehensive catalog of packer systems offered by Baker Hughes, detailing a wide range of products and their applications in well completion and intervention solutions. It highlights the company's commitment to innovation and the development of technologies to optimize energy recovery in the oil and gas industry. Additionally, it includes technical specifications, design features, and operational advantages of various packer types.