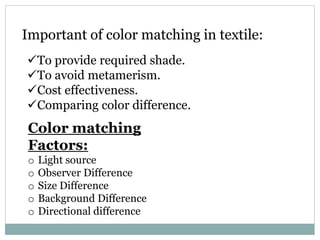

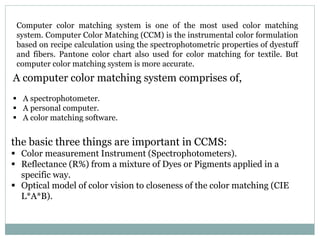

This document discusses color matching in the textile industry. It defines color matching as the process of ensuring a color remains consistent when converted to different mediums. It is important for textiles to provide the required shade, avoid metamerism, be cost effective, and allow for color comparison. Computer color matching systems are highly accurate and commonly used in the industry. They involve a spectrophotometer to measure color, a computer, and color matching software. The systems allow for color prediction, difference calculation, metamerism determination, and more. Advantages of these systems include providing customers the exact shade wanted and choosing optimal formulations faster and with more options.