This document provides an overview of digital color management, color gamut, rendering intent and color communication in textile digital printing. It discusses key topics such as color production and quality control, color communication systems in textile printing, color management systems and ICC profiles, analyzing and characterizing color rendering and reproduction, and ensuring accurate color reproduction through digital color management. The document also reviews color gamuts in different color systems like CMYK and RGB, gamut mapping techniques, and factors that influence the range of reproducible colors.

![1

1. INTRODUCTION

1.1. Definition of Colors

The color of a surface comes from the interpretation by the human visual system of the light

signal reflected or transmitted by the surface, especially its spectral distribution. By normalizing

the measured spectrum by a reference spectrum considered as the maximum signal (direct

incident light for transmittance measurements, and light scattered with a white standard for

reflectance measurements of the CIELAB color space is normally used. The coordinates—

lightness L, green/red coordinate a, and blue/yellow coordinate b can be derived from the

CIEXYZ tristimulus values by nonlinear relations[1].

The colour is one of the most important entities when a consumer purchases an item. Colour is

often the hardest to manage as its appearance and it is subjective and, now that most the

manufacturing of coloured goods are carried out over see, it will becomes increasingly harder to

control the color. The colour of an object depends on with the observer and the quality of the

light. The human beings have a poor color memory, so there is a mechanism help to

communicate with the color. The Color order systems have been used as extensively, and where

the specifier and the supplier each of them have a book of colors and each shades have a unique

reference[2].

Digital Colour display and communication systems are used successfully to complement the

spectrophotometer systems are using input devices, such as optical flatbed scanners and digital

cameras. The Images can be displayed on a calibrated monitor and colored either using

reflectance data from the spectrophotometer or by inputting color values. The advantage of such

systems are that it allow the specifier and the supplier to see the same appearance of a product as

well as having the numeric information, it allows quick and effective decisions will be made.

And The process of communications have to be managed and the information defined and

controlled[2]. The accuracy of Color between the original and final output being optimize using

the Color Management Systems (CMS). The term color managements refer to the use of

software‘s to automatically determine colour reproduction of the characteristics of the input

devices, monitors, and output devices, and also then automatically make the image settings

necessary for optimal color reproduction systems are very important[3].](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-10-320.jpg)

![2

One of the most abundant critical research and development (R&D) areas is the color gamut

analysis, particularly as new colourant sets, pretreatment formulas, and ink-jet heads are

developed. Effective and standard method of colour gamut analysis is needed for a number of

R&D and manufacturing scenarios. For example, if the company wishes to develop a six or

eight-colour ink set, using cyan, magenta, yellow, black (CMYK) as the base four colours,

decisions must be made as to which additional colours will provide the most impact on the

colour gamut[4].

ICC software allows the output profiles to contain four rendering intents - perceptual, absolute

colorimetric, relative colorimetric and saturation. It is possible that to store the intents as

forward lookup the relating profile connection space (PCS) to the device and as reverse lookup

tables relating PCS to the device and a reverse lookup tables relating device to PCS. The

profiles that are going to be used absolute colorimetric in color management systems. and

because we are going to verify the profiles on press with maximum of gamut spacing and

measured colorimetry for the range of color gamut and rendering intents on an object[5].](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-11-320.jpg)

![4

3. LITERATURE REVIEW

3.1. Color in textile industry

Colour is critical in the textile industry both in terms of meeting trends, client requirements and

obtaining consistent colour. The choices a designer makes about the colours in their designs may

come from trend forecasts or be dictated by the brand or textile agent the designer is working for.

Achieving the correct colours and meeting seasonal trends can ensure a product‘s success.

Digital screen colour, a mix of red, green and blue light known as additive colour, has a broader

colour range to printed colour, primarily a mix of cyan, magenta, yellow and black pigment

primaries known as subtractive colour. Whilst there are overlaps between the two colours spaces

there are many colours possible in one but not the other, thus out of gamut[6].

3.1.1. Colour Management and ICC

With the digitalization of the workflow in media production, there arises a demand for a more

effective colour control. The development of different colour management systems became the

solution. A control, based on mathematical equations, through the different conversion steps

became central. The development of such colour management systems very soon created the

need for a standard to be able to communicate colour profile data. The first systems developed

were all vendor specific. The International Colour Consortium (ICC), established in 1993 by

several of the leading companies in the prepress colour industry, created, promoted and

encouraged the standardization of an open, vendor-neutral, cross platform colour management

system architecture[7].

Development of electronic technology and the proliferation of low-cost colour imaging devices

allow more and more users to transfer images between devices (for example, from a computer

screen to a printer). Colour management enables this communication between devices minimal

loss of colour fidelity. This requires that devices be calibrated and characterized and a device

profile constructed for each device .the profile enables the mapping between the device-

independent colorimetric tristimulus data representing the output (CIEXYZ) and the device-

dependent coordinates (typically RGB or CMYK)[8].](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-13-320.jpg)

![5

3.1.2. Colour management in ink jet printing

Color is not a surface or an object. Color is the phenomenon of light reflected from a surface or

object as it is received by the eye and processed by the brain. Light and surfaces will vary, but

even the same conditions can result in differing mental interpretations and verbal descriptions by

a viewer. As the mental interpretation of a physical process, ―color is in the eye of the beholder,‖

and if there is more than one be holder, it is likely that their views will vary. This chapter aims to

detail those issues in color management relevant to printing on textiles by ink jet, rather than

being an exhaustive detailing of the entire field of color management. It considers both the

production of color and the perception of color with the need for individuals to agree on the

perception of a color when in a commercial situation and not all operating with calibrated

equipment. As even different parts of an office can change the perception of a color due to the

quality of the light in that area, this becomes particularly problematic when the individuals in

question are located in different parts of the world[9].

3.1.3. Color print production

One rarely asked but significant question is why one color must match another. Asking this

question allows for an appropriate allocation of resources according to the response, as there are

degrees of justification for expensive and extensive calibration practices. In ―batch matching,‖

there may be little or no allowance for difference and tolerance, particularly for applications such

as military parade uniforms or rolls of curtaining. In this case, calibration deserves the

appropriate amount of time, money, and attention. Some choose to recognize discrepancies

between processes and colors as part of the creative process and an inherent part of print

production. For color schemes, matching may be more relevant across the relative colors

contributing to the overall complimentary look, along with a fast and financially effective color

solution. Detailed color profiling also offers greater accuracy, but does not increase the overall

range of the color gamut. Profiling does not add different color gamuts together. It disregards

colors not reproducible by all, leaving the reduced range of only the shared hues; however,

avoiding calibrating will not change this[9].](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-14-320.jpg)

![6

3.2. Colour gamut in digital textile printing

A ―gamut‖ refers to the range of colors capable of being reproduced by any system of color

mixing. The gamuts of CMYK and RGB overlap; however, it is not an exact overlap, as each

system begins from different starting points. CMYK using its magenta and RGB using its red

will probably each mix a different color. Crucially, as these two systems work differently, they

can mimic each other rather than exactly reproduce each other‘s range of colors. In addition,

many printers use ―light‖ versions of the CMYK inks or an additional set of primaries, such as

red, orange, blue, and a deep or dark black to extend the range of possible colors. Many design

software programs use three variables in an interface, often in two steps to allow users to select

colors. These often correspond to three principle activities involved in producing a color.[9] And

in other words a colour gamut is the area enclosed by a colour space in three dimensions. It is

usual to represent the gamut of a colour reproduction system graphically as the range of colours

available in some device independent colour space. Often the gamut will be represented in only

two dimensions[10].

3.2.1. Gamut mapping

Gamut mapping is perhaps the most crucial part of colour management and research in this field

is extensive. The new gamut mapping algorithm for newsprint. The algorithm is derived from

analysis of high quality colour reproductions. Testing of the algorithms was performed in a

transparency to-newsprint workflow, assumed to be the most severe form of gamut compression

in commercial use. For each physical device in the colour imaging chain, there is a finite range

of colours that can be imaged on a given substrate, depending on factors such as the colorants

used, the densities at which they are imaged, the imaging characteristics of the device, and the

surface properties of the substrate[7].

Since the most notorious color gamut compressions involve reducing the total number of colors

that can be represented then going back to the original values is usually impossible. What has

been lost is lost. So it is best to delay any steps where gamut compression can occur to avoid

reducing the gamut of the data we have. It must be done for output to gamut reduced devices but

it is best to reduce your data in this way only in the last step. The gamut of a color space is the

total set of colors that can be represented within that color space. Typically a device CMYK](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-15-320.jpg)

![7

color space will represent less saturated and fewer colors than an RGB color space. When the

gamut of the source and destination color spaces differs a "gamut mapping" needs to be

performed. Those colors that cannot be represented in the destination need to be altered to colors

that can be represented.

3.2.2. Limitations of colour gamut

When converting colours from the gamut of the original or of the proof to the gamut of the print,

there is often a limit both in size and in shape. The available colour gamut is often smaller and

the conversion of colour values comprises some kind of decision as to what to do with those

colour values that fall outside of the available or reproducible gamut. When reproducing an

original image for printed media, there are certain limitations in the press that will influence the

available colour gamut. The press, with its certain characteristics, will limit the possibilities in

reproduction; the substrate used will limit the gamut, as will the inks or toners used. The

variations in the printing process itself heavily influence the print quality, not least the colour

rendering[7].

3.3. Color Rendering Intent

Rendering Intent: - A method for translating from one color space into another. Rendering

intents are necessary because of the different ―gamuts‖ of devices and Medias. There are four

main rendering intents in the ICC specification: Absolute Colorimetric Relative Colorimetric,

Perceptual, and Saturation. Which one you choose is crucial when gamuts are very different.

Color management provides another way to help in ―managing‖ gamut limitations. If a color

cannot be printed, a color management system helps us find the best replacement. The user can

select from different approaches to finding a replacement color. The methods used to find a

replacement are called rendering intents and typically the rendering intent for a color conversion

is specified in application. The ICC has specified four standard gamut compression schemes,

called rendering intents. The official terms for the rendering intents are perceptual, relative

colorimetric, absolute colorimetric, and saturation. Let‘s look at rendering intents as related to

different image types[11]](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-16-320.jpg)

![8

3.4. Colour Communication

The Colour talk filer supports all colour communication, storage and retrieval. Colours may be

saved either to the system's hard disk or to a 31/2 in floppy disk (which can be sent

through the mail). As colours are stored in terms of their screen CIE XYZ values, they

may be communicated to other Colour Talk systems without loss of fidelity. The filer also

provides another means to enter colours into the system. Using either floppy disk or a network

link, colours may be sent to and from the Coats CPS. This enables physical coloured

samples to be directly measured via the spectrophotometer (attached to the CPS) and be

subsequently reproduced on the screen. In addition, it allows for the prediction of dye

recipes for colours and colour palettes created using the system. Specifying only XYZ data

means that there are usually several possible recipes that can be used to match under

illuminant D65. However, these recipes may not match the target shade under other

lighting conditions. Another approach to the problem of colour constancy is to generate a

pseudo-reflectance curve. This information is ‗illuminant independent‘ meaning that the CPS

can use this to select only those recipes which match under several light sources.

However, it was felt that putting too many constraints on the prediction algorithm could

lead to failure to find any suitable recipe. Additionally, there is no guarantee that pseudo-

reflectance curves will produce a colour- constant shade. Although the representation used by

Colour Talk does not guarantee colour constancy, feedback is available (see later) from

the CPS which can be used to assess this property visually[12].

3.4.1. Effective colour communication for industry

How many times have you agreed to a colour design on a monitor, only to find that the final

version on your fabric is a totally different shade? The problem of mismatch between colours on

screen and on physical materials has been a focus on the result is the Colour Talk system, which

demonstrates that high colour fidelity and effective colour communication can be realized using

modern colour computer systems. Colour specification and communication are also problems for

industry. In practice, many physical colour specification systems (including Pantone, Natural

Color System (NCS) and Munsell Color System) are widely used by industry. Each system

consists of coloured chips arranged in some systematic fashion. Colour information can be](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-17-320.jpg)

![9

communicated using each system‗s own colour coordinates, such as value, chroma and hue (for

Munsell) or blackness, chromaticness and hue (NCS)[13].

3.4.2. Communication between Colour Measuring Instruments

Many people take it for granted that once a colour is measured (i.e. we can express it in numbers,

be they spectral reflectance, X, Y, Z tristimulus or CIELAB values, or some kind of colour

difference) we may freely communicate it, and the result will be perfect understanding of exactly

which colour we mean. Unfortunately, this is not so. There are always some differences between

measurements made on different instruments, even if we make sure that they are in perfect

operating conditions. The performance of colour measuring instruments may be specified

following the ASTM Standard Practice for Specifying and Verifying the Performance of Color-

Measuring Instruments. From the point of view of colour communication reproducibility is

extremely important, because we are generally comparing measurement results from different

locations, if possible between instruments of the same model[14].

3.4.3. Colour measurement, specification and prediction

At the highest levels of potential accuracy CIE L*a*b* colour co-ordinates can be confidently

measured and reproduced as product colours to within a just visible difference that are also

visually correct under more than one illuminant. In practical terms this means that under quality

control the basic CIE X, Y, Z co-ordinates of any given colour must be spectrally specified and

measured to three significant figures (or plus or minus one part in a thousand).This requirement

is demanding, it calls for best practice even from skilled production colorists, and the required

techniques lie well beyond the abilities of most of the other stakeholders in colour

management[15].

3.4.4. Virtual Colour Communication

Communicating colours by numbers is all very well, but what would really be nice is to show

you on your end of the line what I see here on my end which is what virtual colour

communication is all about. Nowadays this appears to be very simple: I have a digital camera or

a scanner, enter the colour (or a complex design of many colours) into some software, send the

file to you over the Internet, and you just see it on your monitor or print it out on your printer. As](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-18-320.jpg)

![10

we shall see, there is more to it than meets the eye (literally). If you ever tried to compare the

image you have on the monitor to the original you have just scanned in, or compare the print

from your printer to the monitor image, or the original you were very likely most disappointed

unless you are using colour management[14].

3.4.5. Device dependent colour

In today‘s world of digital imaging we can‘t really get even acceptable colour reproduction

across the media without colour management, and yet, it is a technique not at all well known, and

even less well understood. Why do we need colour management? To understand this rather

complex problem we have to first think about the different ways colours are produced. The mix

colours from three additive primaries red, green and blue (hence RGB), which works because

human colour perception is also based on RGB primaries, thus additive mixing obeys the laws of

psychophysics. Office printers produces colours by subtractive mixing (obeying the laws of

physics) based on three subtractive primaries yellow, magenta and cyan (hence YMC). For

technical reasons the great majority of these printers use a fourth colour, black (K), and therefore

we usually speak of the YMCK system. Here we are back again to an object colour, prints can be

characterized by their spectral reflectance curves, but these will inevitably be very different from

those of the originals[14].

Figure 1.Object colours (left); additive mixing (middle) and subtractive mixing (right)

3.4.6. Virtual Colour Communication in the Textile and Apparel Industry

In the previous section we have seen how digital communication works beyond traditional,

spectrophotometry-based colorimetry colour. New technologies in image capture and processing](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-19-320.jpg)

![11

together with the technology of colour management have made it possible to communicate not

only the colour of relatively large uniform spots (which may be measured on a conventional

instrument) but also that of complex images.

3.4.7. Colorimetry

To be able to communicate colour and what colour looks like, the special field of colour science,

namely colorimetry, was developed. The need to specify colour in numerical terms forced the

development of a definition of the physically defined stimulus in such a way that (a) when

viewed by an observer with normal color vision, under the same observing conditions, stimuli

with the same specifications look alike (i.e. Are in complete color-match). (b) Stimuli that look

alike have the same specification and (c) the numbers comprising the specifications are

continuous functions of the physical parameters defining the spectral radiant power distribution

of the stimulus.‖[7].](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-20-320.jpg)

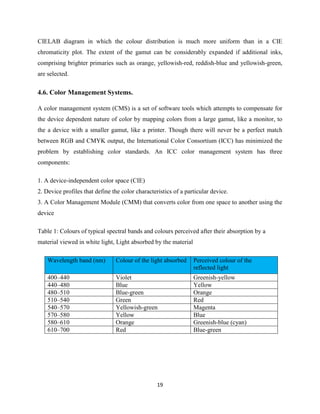

![14

3.3. CIE Tristimulus Values and Metamerism

Colour is three-dimensional; we can describe any colour with three attributes such as the

MUNSELL coordinates Hue, Value and Chroma, or the ones used in the NCS system: hue, white

content and black content. The CIE system of colour measurement reduces spectral data of

objects into three numbers called tristimulus values in such a way that the characteristics of the

illumination and the way a human observer perceives colours are also taken into

consideration[14].

3.4. General numerical colour specifications

Any colour may be specified by three coordinates that locate its position in a three-dimensional

colour space, which is, however, often represented graphically in two dimensions or as a planar

projection. There are a number of standard CIE (Commission International de l'Eclairage) colour

spaces, each varying in its overall uniformity and each having its own coordinates. Three

commonly used colour spaces are determined as follows: CIE xy colour coordinates: XYZ or

xyY (usually depicted as a 2-D, x/y plot). The total range of this colour space represents the

limits of human vision.

CIELAB colour coordinates: L*a*b*, a visually more uniform colour space usually displayed as

a 2-D, a*/b* plot.CIE LCH colour coordinates: LCH (lightness, chroma, hue) sometimes used as

an L/C plot to show the chromatic build-up of a particular colour.](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-23-320.jpg)

![17

will provide a much larger color gamut than a 12-color printer using CMYK with light shades. It

is important, however, to have a balance of colorants to light shades to eliminate visible dither.

When using textile inks such as reactive, acid, or disperse, the full potential of these color spaces

are not realized until the colors have reacted with the fabric, which occurs during post-processing

such as steaming and washing[16].

4.3. Defining and Profiling Color

Figure 5. Diagram of CIE L*a*b color space

CIE L*a*b* color space is one of the color standards used by the textile industry. The CIE,

International Commission on Lighting, realized that every color the human eye perceives could

be defined using three numbers: L* indicates luminosity, lightness from white to black. The* and

b* are the chromaticity coordinates that indicate color directions: +a* is the red direction, -a* is

the green direction, +b* is the yellow direction, and b* is the blue direction. The center is

achromatic, hues of gray. As the a* and b* values increase and the point moves out from the

center, the chroma or purity of the color increases. The pythagorean distance between two color

points plotted in the color space relates to the visual color difference between those two points.

In this way, color variation between points and a standard may be expressed using numbers[16].

Color management and RIP software manage color by creating profiles or characterizations

specific to the printer, ink, fabric and any post-processing, such as steaming and washing. All of

these variables have an impact on color and each variation must be profiled to insure accurate

color match. When a design is printed, a profile is selected based on the printer/ink/media](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-26-320.jpg)

![21

6. REFERENCE

[1] L. Simonot and M. J. J. A. Hébert, "Between additive and subtractive color mixings:

intermediate mixing models," vol. 31, pp. 58-66, 2014.

[2] S. J. O. Williams and L. Technology, "Practical colour management," vol. 38, pp. 399-

404, 2006.

[3] M. Strgar Kurečić, D. Agić, L. J. J. o. I. Mandić, and O. Sciences, "Color Management

implementation in Digital Photography," vol. 31, pp. 47-57, 2007.

[4] Y. Ding, L. Parrillo‐Chapman, and H. S. J. C. T. Freeman, "Developing the methodology

of colour gamut analysis and print quality evaluation for textile ink‐jet printing: Delphi

method," vol. 134, pp. 135-147, 2018.

[5] K. J. Pohnerkar, "Generating ICC Output Profiles for Different Substrates: Application

too a Shinohara Offset Press & Several Printers," 2003.

[6] B. Gooby, M. B. Gooby, and B. UWE, "The development of methodologies for designers

engaging with digital colour inkjet printing in textile design."

[7] M. Klaman, "Adpects on colour rendering, colour prediction and colour control in printed

media," Numerisk analys och datalogi, 2002.

[8] Y. Zhang, V. Cheung, S. Westland, and K. J. J. C. T. Beverley, "Colour management of a

low‐cost four‐colour ink‐jet printing system on textiles," vol. 125, pp. 29-35, 2009.

[9] D. Javoršek and A. J. C. T. Javoršek, "Colour management in digital textile printing,"

vol. 127, pp. 235-239, 2011.

[10] A. Ford and A. J. W. U. Roberts, London, "Colour space conversions," vol. 1998, pp. 1-

31, 1998.

[11] A. Sharma, Understanding color management: John Wiley & Sons, 2018.

[12] P. Rhodes, S. Scrivener, and M. J. D. Luo, "ColourTalk—a system for colour

communication," vol. 13, pp. 89-96, 1992.

[13] R. Luo, P. Rhodes, J. Xin, S. J. J. o. t. S. o. D. Scrivener, and Colourists, "Effective

colour communication for industry," vol. 108, pp. 516-520, 1992.

[14] R. J. R. o. D. I. Hirschler and S. M. Vol, "Electronic colour communication in the textile

and apparel industry," vol. 1, pp. 43-61, 2010.

[15] D. Oulton, "Technology for Colour Management," in Proceedings of the 1st International

Conference on Digital Technologies for the Textile Industries, 2013, p. 6.](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-30-320.jpg)

![22

[16] S. Gordon, "Color Mangement and RIP Software for Digital Textile Printing Managing

Color for Optimal esults," Published by [TC], vol. 2, 2001.](https://image.slidesharecdn.com/seminaroncolorfinal-211221053014/85/Seminar-on-color-final-31-320.jpg)